This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

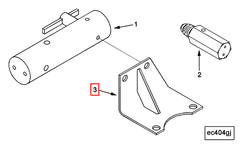

The Safety Control Bracket 188739, manufactured by Cummins, is a component designed to enhance the operation of commercial trucks. This bracket plays a role in ensuring the secure attachment and proper functioning of safety-related systems within the vehicle. Cummins, a well-established manufacturer in the automotive industry, produces this bracket with a focus on reliability and performance 1.

Purpose and Function

The Safety Control Bracket 188739 serves to support and secure various safety mechanisms within a commercial truck. By providing a stable mounting point, it contributes to the overall safety and efficiency of the vehicle. This bracket ensures that safety components are correctly positioned and operate as intended, thereby enhancing the truck’s performance and reliability 2.

Key Features

The Safety Control Bracket 188739 is characterized by several key features that enhance its performance. It is constructed from high-strength materials to ensure durability and longevity. The design incorporates precise engineering to provide a secure fit and easy installation. Additionally, the bracket features corrosion-resistant coatings to protect against environmental factors, ensuring consistent performance over time 3.

Benefits

The advantages of using the Safety Control Bracket 188739 include improved safety, increased durability, and enhanced operational efficiency. By securely mounting safety components, it helps prevent malfunctions and ensures that these systems operate correctly. The robust construction and corrosion-resistant properties contribute to the bracket’s longevity, reducing the need for frequent replacements. Furthermore, the efficient design aids in maintaining the overall performance of the truck.

Installation Process

Installing the Safety Control Bracket 188739 involves several steps to ensure proper attachment and functionality. Begin by identifying the correct mounting location on the truck. Use the appropriate tools to secure the bracket in place, following the manufacturer’s guidelines for torque specifications. Ensure that all safety components are correctly attached to the bracket and that there is no interference with other parts of the truck. Verify the installation by conducting a thorough inspection and testing the secured components.

Maintenance Tips

To ensure the longevity and optimal performance of the Safety Control Bracket 188739, regular maintenance is recommended. Inspect the bracket periodically for signs of wear, corrosion, or damage. Clean the bracket and its mounting area to remove any debris or contaminants that could affect its performance. Check the tightness of all fasteners and re-torque as necessary. Address any issues promptly to prevent further complications and ensure the continued safety and efficiency of the truck.

Troubleshooting Common Issues

Common issues associated with the Safety Control Bracket 188739 may include loose fasteners, corrosion, or damage to the bracket itself. To address these problems, first, inspect the bracket and its attachments for any signs of wear or corrosion. Tighten any loose fasteners and re-torque to the manufacturer’s specifications. If corrosion is present, clean the affected areas and apply a corrosion-resistant coating. For damaged brackets, replacement may be necessary to ensure the safety and functionality of the truck’s systems.

Regulatory Compliance

The Safety Control Bracket 188739 meets industry standards and regulations, ensuring compliance with safety and performance requirements. Cummins adheres to stringent manufacturing processes and quality control measures to produce components that meet or exceed these standards. The bracket may include certifications or compliance details that verify its adherence to industry regulations, providing fleet operators with confidence in its use.

Cummins Overview

Cummins is a renowned manufacturer with a long-standing reputation for producing high-quality automotive components. Founded with a commitment to innovation and excellence, Cummins has established itself as a leader in the industry. Their products are known for reliability, performance, and durability, making them a preferred choice for commercial truck operators. Cummins continues to invest in research and development to enhance their offerings and maintain their position as a trusted manufacturer in the automotive sector.

Cummins Safety Control Bracket 188739 Compatibility

The Cummins Safety Control Bracket, part number 188739, is a critical component designed to enhance the operational safety of various Cummins engines. This bracket is engineered to provide structural support and secure connections within the engine’s control systems, ensuring that all parts remain properly aligned and fastened.

N14 MECHANICAL

For the N14 MECHANICAL engine, the Safety Control Bracket 188739 plays a pivotal role in maintaining the integrity of the engine’s control mechanisms. It is specifically designed to fit seamlessly with the engine’s architecture, ensuring that all safety-related components are correctly positioned and secured. This bracket is essential for the proper functioning of the engine’s safety systems, contributing to overall engine reliability and safety.

NH/NT 855

Similarly, in the NH/NT 855 engines, the Safety Control Bracket 188739 is integral to the engine’s safety infrastructure. This bracket is tailored to fit the unique design of the NH/NT 855 engines, providing the necessary support and alignment for the engine’s control components. Its precise fit ensures that the engine operates safely and efficiently, with all safety-related parts securely in place.

Grouping of Engines

Both the N14 MECHANICAL and NH/NT 855 engines benefit from the use of the Safety Control Bracket 188739, as it is designed to be compatible with the structural and operational requirements of these engines. The bracket’s design allows it to be a versatile component, fitting well within the diverse range of Cummins engines it supports. This compatibility ensures that the bracket can be used across different engine models without compromising its functionality or the engine’s safety standards.

Role of Part 188739 Safety Control Bracket in Engine Systems

The Part 188739 Safety Control Bracket is an integral component in ensuring the secure and efficient operation of various engine systems. It primarily interfaces with the Control Safety mechanism, providing a stable foundation that allows for precise adjustments and reliable performance. This bracket is designed to integrate seamlessly with the Mounting Safety Control, enhancing the overall stability of the safety control apparatus.

In conjunction with the Safety Control system, the bracket facilitates the proper alignment and secure attachment of safety components, which is essential for maintaining operational integrity under varying engine conditions. It also plays a significant role in the Safety Tube Mounting system, where it ensures that the safety tubes are correctly positioned and supported. This is particularly important for maintaining the structural integrity of the safety tubes during engine operation.

Furthermore, the bracket is instrumental in the Tubing Safety Control setup. By providing a robust mounting point, it allows for the safe and efficient routing of tubing, which is vital for the proper functioning of fluid and gas systems within the engine. This ensures that all safety-related tubing is securely held in place, reducing the risk of detachment or misalignment that could lead to operational failures.

Overall, the Part 188739 Safety Control Bracket is a key component in the safe and effective operation of engine systems, offering a reliable interface for various safety mechanisms and ensuring that all connected components are securely and correctly positioned.

Conclusion

The Safety Control Bracket 188739 by Cummins is a vital component for the safe and efficient operation of commercial trucks and various Cummins engines. Its robust construction, precise engineering, and corrosion-resistant features ensure durability and reliable performance. Regular maintenance and proper installation are crucial for maximizing the benefits of this part, contributing to the overall safety and efficiency of the vehicle.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.