This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 204960 Lifting Bracket, manufactured by Cummins, is a specialized component designed for use in commercial trucks. Cummins, a well-established name in the diesel engine and component industry, produces this lifting bracket to aid in the maintenance and operational efficiency of heavy-duty trucks. Lifting brackets play a significant role in the safe handling and securing of truck components during maintenance and repair procedures 1.

Basic Concepts of Lifting Brackets

Lifting brackets are mechanical devices used across the automotive industry to support and secure components during maintenance or repair. In heavy-duty trucks, these brackets are essential for safely lifting and positioning large and heavy parts, such as engines or transmissions, facilitating easier and more efficient service work. They function by providing a secure attachment point for lifting equipment, ensuring that components are held firmly in place during the lifting process 2.

Purpose of the 204960 Lifting Bracket

The 204960 Lifting Bracket is specifically designed to support and secure heavy components in commercial trucks. It plays a role in ensuring the stability and safety of these components during lifting operations, which is vital for the integrity of the maintenance process. By providing a robust and reliable attachment point, this bracket helps in the precise and secure handling of truck parts, reducing the risk of accidents and component damage 3.

Key Features

The 204960 Lifting Bracket boasts several key features that enhance its durability and functionality. It is constructed from high-strength materials, ensuring it can withstand the rigors of heavy-duty use. The design incorporates elements that promote easy installation and secure attachment, while unique attributes such as corrosion resistance and precise engineering set it apart from other lifting brackets in the market.

Benefits

Using the 204960 Lifting Bracket offers several advantages. It enhances safety during lifting operations by providing a secure and stable attachment point. Its durable construction leads to a longer service life, reducing the frequency of replacements. Additionally, the bracket can contribute to cost savings by minimizing maintenance needs and the risk of component damage during lifting procedures.

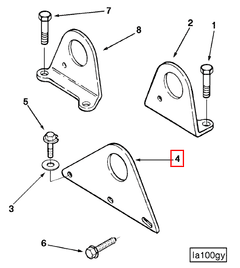

Installation Process

Installing the 204960 Lifting Bracket requires careful attention to detail and adherence to safety protocols. The process involves securing the bracket to the truck frame or component it is designed to support, ensuring all fasteners are tightened to the manufacturer’s specifications. Best practices include verifying the bracket’s alignment and stability before commencing any lifting operations. Safety precautions, such as wearing appropriate personal protective equipment and ensuring the work area is clear of obstacles, are paramount.

Troubleshooting and Maintenance

Common issues with the 204960 Lifting Bracket may include corrosion, wear, or loose fasteners. Troubleshooting steps involve inspecting the bracket for signs of damage or wear, tightening any loose fasteners, and addressing corrosion with appropriate treatments. Regular maintenance, including inspections and cleaning, can prolong the life of the bracket and ensure it continues to function safely and effectively.

Safety Considerations

Adhering to safety protocols when using the 204960 Lifting Bracket is crucial. Improper use can lead to risks such as component failure during lifting, posing a danger to personnel and potentially causing damage to the truck. Mitigating these risks involves following the manufacturer’s guidelines for installation and use, conducting regular inspections, and ensuring all personnel are trained in safe lifting practices.

Cummins: Manufacturer Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes diesel and natural gas engines, as well as related technologies. With a rich history in the automotive industry, Cummins is renowned for its expertise in diesel engines and components, including the 204960 Lifting Bracket. The company’s commitment to quality, innovation, and customer satisfaction has established it as a trusted name in the commercial truck sector.

Cummins Lifting Bracket 204960 in Engine Applications

The Cummins Lifting Bracket 204960 is a critical component in the installation and maintenance of various Cummins engines. This part is specifically designed to ensure secure and efficient lifting of the engine during assembly, disassembly, and maintenance procedures. It is engineered to withstand the rigors of engine handling, providing a reliable connection point for lifting equipment.

N14 Mechanical Engines

In the N14 Mechanical engine series, the Lifting Bracket 204960 is integral to the engine’s structural integrity during maintenance operations. This bracket is strategically placed to support the engine’s weight, ensuring that the lifting process is both safe and effective. The precise fit and robust construction of the bracket are essential for preventing damage to the engine and ensuring the safety of maintenance personnel.

Grouping of Engines

The Cummins Lifting Bracket 204960 is compatible with a range of Cummins engines, including but not limited to the N14 Mechanical series. Its design allows for versatility across different engine models, making it a valuable tool in the maintenance toolkit for these engines. The bracket’s compatibility extends to various configurations within the engine group, providing a standardized solution for lifting needs.

Role of Part 204960 Lifting Bracket in Engine Systems

The Part 204960 Lifting Bracket is integral to the structural integrity and operational efficiency of various engine systems. It is primarily used in the arrangement and securement of components, ensuring that they remain in the correct position during operation.

Integration with Engine Components

-

Lifting Arrangement: The Lifting Bracket is often part of the lifting arrangement in engine systems. It provides a stable and secure point for lifting and moving heavy engine components during maintenance or installation. This ensures that the components are handled safely and efficiently.

-

EBM (Engine Bracket Mounting): In engine bracket mounting systems, the Lifting Bracket plays a key role. It helps in the precise alignment and secure attachment of engine brackets, which are essential for the proper functioning of the engine. This includes supporting various engine parts and ensuring they operate within specified tolerances.

-

Brake System: When integrated with the lifting braket system, the Lifting Bracket assists in the secure mounting of brake components. This is vital for the reliable operation of the braking system, ensuring that all parts are correctly aligned and under the appropriate tension.

-

General Lifting Operations: Beyond specific systems, the Lifting Bracket is used in general lifting operations within engine maintenance. It provides a robust connection point for lifting equipment, facilitating the safe movement of engine parts without risk of damage or misalignment.

Operational Benefits

The use of the Lifting Bracket in these systems offers several operational benefits. It enhances the safety of maintenance procedures by providing secure points for lifting and moving components. Additionally, it contributes to the overall reliability of the engine system by ensuring that all parts are correctly positioned and supported. This can lead to improved performance and longevity of the engine components.

Conclusion

The 204960 Lifting Bracket by Cummins is a vital component in the maintenance and operational efficiency of commercial trucks and heavy-duty engines. Its robust design, compatibility with various engine models, and integration into critical engine systems underscore its importance in ensuring safe and efficient maintenance procedures. Regular maintenance and adherence to safety protocols are essential to maximize the benefits and longevity of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.