This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

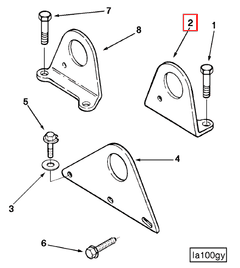

The Cummins 204961 Lifting Bracket is a specialized component designed for use in commercial trucks. Its primary role is to facilitate the safe and efficient lifting and securing of heavy components during maintenance and repair operations. A lifting bracket, in general, is a device used in the automotive industry to provide a secure point of attachment for lifting equipment, ensuring that components are handled safely and effectively 2.

Purpose and Function

This Cummins part is engineered to support the lifting and securing of substantial truck components. It plays a role in maintenance operations by providing a stable and reliable attachment point for lifting equipment. This ensures that components are lifted without risk of damage or injury. Secure mounting and lifting are vital in heavy-duty truck maintenance to prevent accidents, ensure component integrity, and maintain operational efficiency 1.

Key Features

The 204961 boasts several key features that enhance its functionality. It is constructed from high-strength materials, ensuring durability and resistance to wear and tear. The design incorporates robust mounting points and a sturdy frame, which contribute to its strength and reliability. Additionally, the bracket is engineered for ease of use, allowing for quick and secure attachment during maintenance procedures.

Benefits

This part offers several benefits that contribute to safer and more efficient truck maintenance. Its design enhances safety during lifting operations by providing a secure attachment point, reducing the risk of accidents. The bracket’s durability and reliability ensure long-term use, minimizing the need for frequent replacements. These attributes contribute to efficient maintenance processes and help reduce downtime for commercial trucks.

Installation and Usage

Proper installation and usage of the 204961 are crucial for its effective performance. Installation involves identifying the correct mounting points on the truck and ensuring the bracket is securely attached. It is important to follow the manufacturer’s guidelines to achieve optimal performance and safety. Regular checks should be performed to ensure the bracket remains securely fastened during use.

Troubleshooting and Maintenance

Common issues with lifting brackets may include wear and tear or loose mounting points. Troubleshooting steps involve inspecting the bracket for signs of damage or wear and ensuring all mounting points are secure. Regular maintenance, such as cleaning and checking for corrosion, can help prolong the life of the bracket. It is also important to replace the bracket if it shows signs of significant wear or damage to maintain safety and effectiveness.

Safety Considerations

When using lifting brackets, safety practices are paramount. Personnel should receive proper training on the correct use of lifting equipment and brackets. Adhering to safety standards and regulations relevant to lifting operations in commercial truck maintenance is crucial. This includes understanding load limits, using appropriate personal protective equipment, and ensuring all equipment is in good working condition before use 2.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and commitment to quality, Cummins plays a significant role in the automotive and engine manufacturing industry. The company’s dedication to producing reliable and high-performance components is evident in products like the 204961, which is designed to meet the demanding requirements of commercial truck maintenance.

Cummins Lifting Bracket 204961 Compatibility

The Cummins Lifting Bracket part number 204961 is a versatile component designed to fit various Cummins engines. This bracket is essential for safely lifting and supporting the engine during maintenance or installation processes. Here is a detailed look at its compatibility with specific Cummins engines:

N14 MECHANICAL Engines

The Cummins Lifting Bracket 204961 is specifically engineered to fit the N14 MECHANICAL engines. This bracket ensures secure attachment and provides the necessary support to lift the engine without causing damage. Its design accommodates the unique structural features of the N14 MECHANICAL engine, making it an ideal choice for maintenance and repair tasks.

NH/NT 855 Engines

Similarly, the Cummins Lifting Bracket 204961 is also compatible with the NH/NT 855 engines. This bracket is designed to fit the specific dimensions and mounting points of the NH/NT 855, ensuring a secure and stable lift. Its robust construction and precise fit make it an essential tool for technicians working on these engines.

Grouping for Efficiency

When working with multiple Cummins engines, the 204961 Lifting Bracket offers a streamlined solution. Its compatibility with both the N14 MECHANICAL and NH/NT 855 engines allows for efficient inventory management and reduces the need for multiple specialized parts. This versatility enhances operational efficiency, making it a preferred choice for workshops and maintenance facilities that service a variety of Cummins engines.

Role of Part 204961 Lifting Bracket in Engine Systems

The Part 204961 Lifting Bracket is an essential component in the arrangement and secure handling of various engine systems. It is specifically designed to facilitate the lifting and mounting processes of engines, ensuring stability and safety during maintenance, installation, or removal procedures.

Integration with Engine Mounting and Front Engine Support

In engine mounting applications, the Lifting Bracket (Part 204961) works in conjunction with the Front Engine Support to provide a robust framework. This setup allows for the even distribution of weight and stress across the engine during lifting operations. The Bracket ensures that the Front Engine Support remains aligned and secure, minimizing the risk of misalignment or damage to the engine or supporting structures.

Coordination with Heat Exchanger and PDC Systems

When dealing with Heat Exchanger units, the Lifting Bracket plays a significant role in the safe handling of these components. It is often integrated into the Lifting Arrangement to support the weight of the Heat Exchanger, ensuring it is lifted without causing strain on the connections or pipes. Similarly, in Power Distribution Center (PDC) systems, the Bracket aids in the secure lifting of the PDC, maintaining the integrity of electrical connections and preventing any potential hazards.

Use in Lifting Kits and Front Lifting Brackets

Part 204961 is a common component in Lifting Kits, where it is used alongside other Brackets and Base Parts to create a comprehensive Lifting Arrangement. In scenarios involving the Front Lifting Bracket, this part ensures that the front section of the engine or related components is lifted smoothly and without risk of tipping or instability.

Application in Engine Maintenance and Replacement

During engine maintenance or replacement, the Lifting Bracket is employed in conjunction with the Mounting Engine components to facilitate the secure removal and reinstallation of the engine. It interacts with the Front Lifting Bracket and other Bracket components to provide a stable lifting point, ensuring that the engine can be maneuvered safely into position without causing damage to surrounding parts or the engine itself.

Enhanced Safety in Complex Lifting Operations

In more complex lifting operations, such as those involving the EBM (Engine Bracket Mounting) system, the Lifting Bracket (Part 204961) is critical. It ensures that the engine and its associated brackets are lifted in unison, maintaining the structural integrity of the engine system. This is particularly important in scenarios where the engine is heavily integrated with other components, such as the Heat Exchanger or PDC.

Conclusion

Overall, the Part 204961 Lifting Bracket is a versatile and indispensable component in the safe and efficient handling of engine systems, providing essential support and stability in a variety of applications. Its robust design, compatibility with various Cummins engines, and integration with other engine components make it a critical tool for technicians and maintenance professionals.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.