This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Marine Gear Bracket 208665, manufactured by Cummins, is a specialized component designed for heavy-duty truck operations. This bracket plays a role in the drivetrain system, ensuring the efficient transfer of power from the engine to the transmission. Cummins, a well-established manufacturer in the automotive industry, is known for its commitment to quality and innovation in producing reliable truck components 1.

Basic Concepts of Marine Gear Brackets

A Marine Gear Bracket is a structural component that supports and aligns the marine gear within the drivetrain system. It interfaces with various parts such as the transmission, engine, and driveshaft, facilitating the smooth operation of the vehicle. The mechanical principles involved include torque management, vibration dampening, and precise alignment to ensure optimal performance and longevity of the drivetrain components 2.

Purpose of the 208665 Marine Gear Bracket

The 208665 Marine Gear Bracket is specifically engineered to enhance the operation of heavy-duty trucks. It plays a role in maintaining the alignment and stability of the marine gear, which is crucial for the efficient transfer of power. By ensuring proper alignment, the bracket contributes to the overall performance and efficiency of the vehicle, reducing the likelihood of drivetrain issues and enhancing the truck’s operational reliability 3.

Key Features

The 208665 Marine Gear Bracket is designed with several features that enhance its functionality. Constructed from high-strength materials, it offers durability and resistance to wear and tear. The engineering specifications ensure precise fitment and alignment, while unique attributes such as corrosion-resistant coatings and vibration-dampening properties further enhance its performance in demanding environments 4.

Benefits

Using the 208665 Marine Gear Bracket in truck operations offers several advantages. Its robust construction ensures durability and reliability, even under heavy-duty conditions. The precise engineering enhances the performance of the drivetrain system, leading to improved efficiency and reduced maintenance requirements. Additionally, the cost-effectiveness of the bracket makes it a valuable component for fleet operators looking to maximize their investment in vehicle maintenance and performance 5.

Installation Process

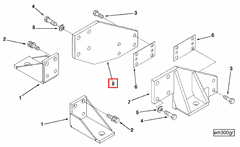

Proper installation of the 208665 Marine Gear Bracket is crucial for ensuring its effectiveness. The process involves several steps, including preparing the mounting surface, aligning the bracket with the marine gear, and securing it in place using the appropriate fasteners. Tools such as torque wrenches and alignment tools may be required, and safety precautions, including wearing protective gear and ensuring the vehicle is securely supported, should be observed throughout the installation process 6.

Maintenance and Troubleshooting

Regular maintenance of the 208665 Marine Gear Bracket is important for ensuring its longevity and optimal performance. This includes periodic inspections for signs of wear, corrosion, or misalignment. Common issues that may arise include loose fasteners, corrosion, or damage to the bracket itself. Troubleshooting tips include tightening fasteners to the specified torque, applying corrosion-resistant coatings, and replacing damaged components as necessary. Following these guidelines helps maintain the integrity of the drivetrain system and prevents potential failures 7.

Cummins: Manufacturer Overview

Cummins Inc. is a leading manufacturer in the automotive industry, with a strong reputation for producing high-quality truck components. Founded with a commitment to innovation and excellence, Cummins has a long history of delivering reliable and efficient solutions for heavy-duty applications. The company’s dedication to quality is evident in its rigorous manufacturing processes and continuous investment in research and development, ensuring that its products meet the demanding requirements of modern truck operations 8.

Role of Part 208665 Marine Gear Bracket in Engine Systems

The Part 208665 Marine Gear Bracket is an integral component in the assembly and operation of marine engine systems. It serves as a pivotal connection point between the engine and the gear system, ensuring stability and efficient power transmission.

Integration with Engine and Gear Bracket

When integrating the Marine Gear Bracket with the engine, it acts as a secure mounting point. This bracket is designed to withstand the dynamic forces generated during engine operation, providing a stable foundation for the gear system. The bracket’s precise engineering allows for optimal alignment of the gear components, which is essential for smooth and reliable operation 9.

Function in Engine Mounting

In the context of engine mounting, the Marine Gear Bracket plays a significant role in distributing the engine’s weight and vibrational forces. It is attached to the engine block and the surrounding structure, ensuring that the engine remains firmly in place. This stability is vital for maintaining the integrity of the engine’s components and preventing undue stress on the mounting points 10.

Interaction with Gear System

The bracket facilitates the connection between the engine and the gear system, allowing for the efficient transfer of power from the engine to the propulsion system. This interaction is crucial for the overall performance of the marine vessel, as it ensures that the engine’s output is effectively utilized to drive the gears and, subsequently, the propeller 11.

Enhanced Durability and Performance

By providing a robust and reliable connection, the Marine Gear Bracket contributes to the durability and performance of the engine system. Its design considerations include factors such as material strength, corrosion resistance, and fatigue life, ensuring that it can endure the harsh marine environment without compromising functionality 12.

Conclusion

In summary, the Part 208665 Marine Gear Bracket is a key component in the integration of engine and gear systems, offering stability, efficient power transmission, and enhanced durability. Its robust construction, precise engineering, and unique features make it a valuable component for heavy-duty truck operations, contributing to the overall performance and reliability of the vehicle.

-

Hilgers, M. (2023). Alternative Powertrains and Extensions to the Conventional Powertrain. Springer Nature.

↩ -

Awari, G.K., Kumbhar, V.S., & Tirpude, R.B. (2011). Automotive Systems Principles and Practice. CRC Press.

↩ -

Smil, V. (2010). The History and Impact of Diesel Engines and Gas Turbines. The MIT Press.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5659635.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5659635.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5659635.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5659635.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5659635.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5659635.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5659635.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5659635.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5659635.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.