This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Corrosion Resistor Bracket, part number 208759, is a component manufactured by Cummins, a prominent name in the commercial truck industry. This bracket is designed to enhance the durability and reliability of truck components by providing superior resistance to corrosion. Its role is particularly significant in environments where trucks are exposed to harsh conditions, such as moisture, salt, and other corrosive elements.

Purpose and Function

The Corrosion Resistor Bracket plays a role in protecting critical components of a truck from the adverse effects of corrosion. It is typically positioned in areas where metal parts are vulnerable to environmental damage. By securing and supporting these components, the bracket ensures that they remain intact and functional over time. Its interaction with other components is crucial for maintaining the structural integrity and operational efficiency of the truck.

Key Features

This Cummins part is constructed from high-quality materials that offer excellent resistance to corrosion. Its design includes features such as a robust frame and precise mounting points, which ensure a secure fit and long-lasting performance. Additionally, the bracket may incorporate unique attributes like a protective coating or specialized alloys that further enhance its durability and effectiveness in challenging environments.

Benefits

One of the primary advantages of the Corrosion Resistor Bracket is its ability to withstand harsh environmental conditions, which helps in prolonging the life of connected components. This results in reduced maintenance costs and increased reliability of the truck. Furthermore, the bracket contributes to the overall performance and safety of the vehicle by ensuring that critical parts remain in optimal condition.

Installation Considerations

Proper installation of the Corrosion Resistor Bracket is vital for its effectiveness. It is recommended to follow specific guidelines, which may include preparatory steps such as cleaning the installation area and ensuring that all mounting points are free from debris. The use of appropriate tools and alignment procedures is also important to achieve a secure and accurate fit. Detailed instructions provided by Cummins should be consulted to ensure correct installation.

Maintenance and Troubleshooting

Routine maintenance of the Corrosion Resistor Bracket involves inspecting it for signs of wear or damage and ensuring that it remains securely attached. Any corrosion or deterioration should be addressed promptly to prevent further damage to connected components. Common issues may include loosening of the bracket or corrosion at the mounting points. Troubleshooting steps typically involve re-tightening fasteners or applying a protective coating to affected areas.

Environmental and Operational Factors

Various environmental conditions, such as exposure to moisture, salt, and extreme temperatures, can impact the performance of the Corrosion Resistor Bracket. Operational factors, including the type of cargo transported and the frequency of use, also play a role. To mitigate potential issues, it is advisable to implement regular inspections and maintenance practices. Additionally, storing the truck in a protected environment when not in use can help preserve the bracket’s integrity.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its wide range of high-quality components and engines. With a history spanning several decades, Cummins has built a reputation for reliability and innovation. The company’s commitment to excellence is reflected in its products, including the Corrosion Resistor Bracket Part #208759, which embodies the quality and durability that Cummins is renowned for 1.

Application in NH/NT 855 Engines

In the NH/NT 855 engines, the Corrosion Resistor Bracket 208759 plays a pivotal role in protecting sensitive engine components from the damaging effects of corrosion. These engines, known for their robust performance and reliability, benefit significantly from the strategic placement of this bracket. By providing a barrier against corrosive elements, it helps maintain the integrity of the engine’s structure and function 2.

Integration with Other Cummins Engines

The Corrosion Resistor Bracket 208759 is also compatible with a range of other Cummins engines. Its design allows for seamless integration into various engine configurations, ensuring that it can be utilized across different models. This versatility makes it a valuable component for maintaining engine health and performance in a wide array of applications.

Importance of the Corrosion Resistor Bracket

The importance of the Corrosion Resistor Bracket 208759 cannot be overstated. Its primary function is to protect critical engine components from corrosion, which can otherwise lead to costly repairs and downtime. By providing a durable and reliable solution, this bracket helps ensure that the engine operates at peak efficiency, contributing to the overall reliability and longevity of the engine system.

Compatibility and Installation

When installing the Corrosion Resistor Bracket 208759, it is crucial to follow the manufacturer’s guidelines to ensure proper fit and function. This bracket is designed to be easy to install, with precise dimensions and mounting points that align with the specific requirements of the engine it is being fitted to. Proper installation is key to maximizing the benefits of this component, ensuring that it effectively protects the engine from corrosion.

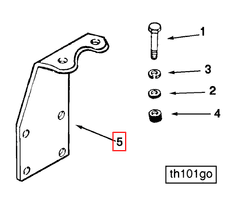

Role of Part 208759 Corrosion Resistor Bracket in Engine Systems

The Part 208759 Corrosion Resistor Bracket is an essential component in various engine systems, primarily designed to enhance durability and performance under harsh conditions. This bracket is integral in securing and supporting the Corrosion Resistor, which is often situated near the Thermostat Housing.

When installed, the Corrosion Resistor Bracket ensures that the Corrosion Resistor remains firmly in place, minimizing the risk of displacement or damage during engine operation. This stability is vital for the consistent performance of the resistor, which plays a significant role in regulating temperature and preventing corrosion within the engine system.

Additionally, the bracket’s design allows for efficient heat dissipation from the Corrosion Resistor, contributing to the overall thermal management of the engine. This is particularly important in high-stress environments where temperature fluctuations can lead to component failure.

The integration of the Corrosion Resistor Bracket with the Mounting system ensures a secure fit, reducing vibrations and stress on the Corrosion Resistor. This mounting solution is engineered to withstand the rigors of engine operation, providing a reliable platform for the Corrosion Resistor to function effectively.

Conclusion

In summary, the Part 208759 Corrosion Resistor Bracket is a key component in maintaining the integrity and performance of the engine system, particularly in relation to the Corrosion Resistor and Thermostat Housing. Its robust design and secure mounting contribute significantly to the longevity and efficiency of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.