This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

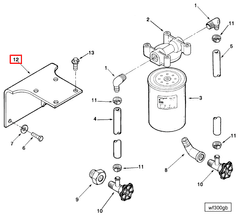

The Corrosion Resistor Bracket 212779 is a component designed for use in heavy-duty truck applications. Its primary role is to provide structural support and protection against corrosion for various engine components. This bracket is significant in maintaining the integrity and longevity of truck engines, particularly in harsh operating environments.

Purpose and Function

The Corrosion Resistor Bracket 212779 is positioned to support and secure specific engine components, ensuring they remain in place and function correctly. It interacts with other parts of the engine system, providing a stable mounting point and protecting against environmental factors that could lead to corrosion. This bracket is integral to the overall operation of the truck, contributing to the stability and reliability of the engine.

Key Features

The Corrosion Resistor Bracket 212779 is constructed from materials that offer superior resistance to corrosion, such as high-grade steel or specialized alloys. Its design includes features like protective coatings and precise engineering to ensure a snug fit and effective protection. These characteristics enhance its performance and durability in demanding conditions.

Benefits

The advantages of using the Corrosion Resistor Bracket 212779 include improved durability and resistance to environmental factors. Its design helps protect engine components from corrosion, which can extend the lifespan of the truck and reduce maintenance costs. Additionally, the bracket contributes to the overall reliability of the truck by ensuring that engine components remain securely in place and function as intended.

Installation Considerations

Proper installation of the Corrosion Resistor Bracket 212779 involves several steps to ensure it is securely and correctly fitted. Preparatory steps may include cleaning the mounting area and inspecting the bracket for any damage. Tools required for installation might include wrenches, screwdrivers, and possibly a torque wrench to ensure bolts are tightened to the manufacturer’s specifications. Following the manufacturer’s guidelines for installation is recommended to achieve the best results.

Maintenance and Troubleshooting

Routine maintenance of the Corrosion Resistor Bracket 212779 involves inspecting it for signs of corrosion or structural damage. Regular cleaning and applying protective coatings can help maintain its condition. Troubleshooting common issues, such as corrosion or loosening of the bracket, may involve reapplying protective coatings or tightening bolts as necessary. Addressing these issues promptly can help prevent more significant problems down the line.

Environmental and Operational Factors

Various environmental and operational conditions can affect the performance and longevity of the Corrosion Resistor Bracket 212779. Exposure to moisture, salt, and other corrosive elements can accelerate corrosion, while high temperatures and vibrations can impact the bracket’s structural integrity. Understanding these factors and taking appropriate measures to mitigate their effects is important for maintaining the bracket’s effectiveness.

Cummins Overview

Cummins Inc. is a leading manufacturer in the heavy-duty truck industry, known for its wide range of engine and power generation products. With a history of innovation and quality, Cummins has established a strong reputation for producing reliable and durable components. The company’s commitment to excellence is reflected in its products, including the Corrosion Resistor Bracket 212779, which is designed to meet the demanding requirements of heavy-duty applications.

Integration with Engine Components

The Corrosion Resistor Bracket 212779 is instrumental in maintaining the integrity and efficiency of various engine components. This bracket is specifically designed to resist corrosion, ensuring longevity and reliable performance in harsh environments.

-

Exhaust Manifold: The Corrosion Resistor Bracket secures the exhaust manifold to the engine block. Its resistance to corrosion prevents degradation from exhaust gases and heat, ensuring a stable connection over time.

-

Turbocharger Mounting: In turbocharged engines, this bracket is used to mount the turbocharger to the engine. The corrosion-resistant properties are vital in withstanding the high temperatures and pressures associated with turbocharging.

-

Heat Shield Attachment: Heat shields are often attached using this bracket to protect nearby components from excessive heat. Its durability ensures that the heat shield remains securely in place, providing consistent protection.

-

Intercooler Support: In engines equipped with intercoolers, the bracket supports the intercooler piping and components. Its resistance to corrosion is essential in environments where the intercooler may be exposed to moisture and road salts.

-

Accessory Drive Belt Tensioner: The bracket is also employed to secure the accessory drive belt tensioner. This ensures that the belt remains properly tensioned, contributing to the efficient operation of accessories like the alternator and power steering pump.

-

Engine Mount Reinforcement: In some applications, the Corrosion Resistor Bracket reinforces engine mounts. This added support helps in maintaining the structural integrity of the engine within the vehicle chassis.

-

Sensor and Wiring Harness Support: Various sensors and wiring harnesses are often supported by this bracket. Its corrosion-resistant nature ensures that these critical components remain protected and functional, even in adverse conditions.

Conclusion

The Corrosion Resistor Bracket 212779 by Cummins is a vital component in heavy-duty truck applications, designed to enhance the durability and longevity of engine systems. By providing structural support and protection against corrosion, this bracket ensures that engine components remain securely in place and function correctly, even in harsh operating environments. Its integration with various engine components, such as the exhaust manifold, turbocharger, and intercooler, underscores its importance in maintaining the overall performance and reliability of the engine. Regular maintenance and proper installation are key to maximizing the benefits of this bracket, contributing to the extended lifespan and reduced maintenance costs of heavy-duty trucks.

, , , ,

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.