This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

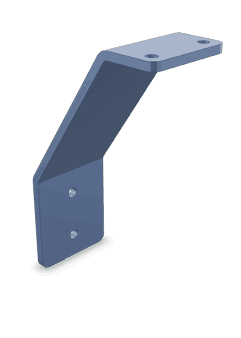

The Ignition Coil Bracket 2878615, manufactured by Cummins, is a component designed for use in commercial truck engines. Cummins, a well-established name in the automotive industry, is known for producing reliable and high-quality engine components. This Cummins part is significant in ensuring the proper functioning of the ignition system in trucks, contributing to overall engine performance and reliability.

Basic Concepts of Ignition Coil Brackets

An ignition coil bracket serves as a mounting point for the ignition coil within the engine’s ignition system. Its primary function is to secure the ignition coil in place, ensuring it remains stable during engine operation. The bracket also plays a role in maintaining proper electrical connections between the ignition coil and other components of the ignition system, such as the spark plugs. This ensures efficient transmission of electrical energy required for igniting the air-fuel mixture in the engine cylinders 1.

Purpose of the 2878615 Ignition Coil Bracket

The 2878615 Ignition Coil Bracket is specifically designed to secure the ignition coil in commercial truck engines. By holding the ignition coil firmly in place, it ensures that the coil remains stable under the vibrations and stresses encountered during engine operation. This stability is crucial for maintaining consistent electrical connections, which in turn supports reliable ignition and combustion processes. Proper installation and maintenance of the bracket contribute to the overall efficiency and performance of the engine 2.

Key Features

The 2878615 Ignition Coil Bracket is constructed from high-quality materials, ensuring durability and resistance to corrosion. Its design includes precise mounting points that align perfectly with the ignition coil and engine components, facilitating easy installation and secure fitting. The bracket may also feature additional elements such as insulation materials to protect against electrical interference and enhance safety. These features contribute to the bracket’s performance and longevity in demanding engine environments 3.

Benefits

The use of the 2878615 Ignition Coil Bracket offers several benefits. It contributes to improved engine performance by ensuring stable and reliable operation of the ignition system. The secure mounting of the ignition coil leads to consistent spark delivery to the spark plugs, enhancing combustion efficiency. Additionally, the bracket’s design and material construction support long-term reliability and ease of maintenance, reducing the likelihood of ignition-related issues and facilitating straightforward replacement or repair procedures when necessary.

Installation Process

Installing the 2878615 Ignition Coil Bracket involves several steps to ensure proper fitting and functionality. Begin by locating the designated mounting points on the engine. Align the bracket with these points and secure it in place using the provided fasteners. Ensure that the ignition coil is correctly positioned within the bracket and that all electrical connections are firmly established. It is important to follow the manufacturer’s instructions carefully to avoid damage to the components and to ensure optimal performance.

Common Issues and Troubleshooting

Common issues with the 2878615 Ignition Coil Bracket may include loose connections, corrosion, or physical damage to the bracket itself. Troubleshooting these problems involves inspecting the bracket and its connections for signs of wear or damage. Tightening loose fasteners, cleaning corroded surfaces, or replacing damaged components can often resolve these issues. Regular maintenance and inspection can help prevent such problems from arising.

Maintenance Tips

To ensure the longevity and optimal performance of the 2878615 Ignition Coil Bracket, regular maintenance is recommended. This includes periodic inspection of the bracket and its connections for signs of wear, corrosion, or damage. Cleaning the bracket and its surroundings can prevent the buildup of dirt and debris that may interfere with electrical connections. Following the manufacturer’s guidelines for maintenance intervals and procedures will help maintain the bracket’s condition and contribute to the overall reliability of the engine’s ignition system.

Cummins Overview

Cummins is a renowned manufacturer in the automotive industry, with a history of producing high-quality engine components. The company is known for its commitment to innovation, quality, and customer satisfaction. Cummins’ reputation is built on a foundation of reliable products that meet the demanding requirements of commercial and industrial applications. The Ignition Coil Bracket 2878615 is a testament to Cummins’ dedication to providing components that enhance engine performance and durability.

Ignition Coil Bracket 2878615 Compatibility with Cummins Engines

The Ignition Coil Bracket part number 2878615, manufactured by Cummins, is designed to fit seamlessly with several of their engine models. This bracket is a critical component in the ignition system, ensuring that the ignition coil is properly positioned and secured within the engine compartment.

G8.3 CM558 Engines

The G8.3 CM558 engine series is one of the key applications for the Ignition Coil Bracket 2878615. This engine is known for its robust performance and reliability, often used in heavy-duty applications. The bracket’s design ensures that the ignition coil is held firmly in place, preventing any movement that could disrupt the ignition process and lead to performance issues.

Grouping of Compatible Engines

While the G8.3 CM558 is a notable example, the Ignition Coil Bracket 2878615 is also compatible with other Cummins engine models that share similar design and mounting requirements. This compatibility extends to various engine configurations, ensuring that the bracket can be used across a range of applications without modification.

By ensuring a secure fit, the bracket contributes to the overall efficiency and longevity of the ignition system, making it a vital part for maintaining engine performance.

Role of Part 2878615 Ignition Coil Bracket in Engine Systems

The Ignition Coil Bracket (Part 2878615) serves as a foundational component in the arrangement of the ignition system within various engine setups. This bracket securely holds the ignition coil in place, ensuring it remains stable and correctly aligned with other ignition system components.

In the ignition system, the coil is responsible for transforming the battery’s low voltage into the high voltage needed to create a spark at the spark plugs. The Ignition Coil Bracket not only supports the coil but also aids in dissipating heat generated during operation, contributing to the overall efficiency and reliability of the ignition process.

Moreover, the bracket facilitates easy access for maintenance and replacement of the ignition coil, which is essential for routine engine servicing. Its design allows for precise alignment with the distributor or direct ignition system, depending on the engine’s configuration, ensuring optimal performance and consistent spark delivery.

In summary, the Ignition Coil Bracket (Part 2878615) plays a significant role in maintaining the structural integrity and functional efficiency of the ignition system within engine arrangements.

Conclusion

The Ignition Coil Bracket 2878615, manufactured by Cummins, is a critical component in the ignition systems of commercial truck engines. Its role in securing the ignition coil ensures stable and reliable engine performance. The bracket’s design, featuring high-quality materials and precise mounting points, contributes to its durability and ease of maintenance. Regular inspection and maintenance of this part are essential for preventing common issues such as loose connections and corrosion, thereby ensuring the longevity and efficiency of the engine’s ignition system.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.