This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

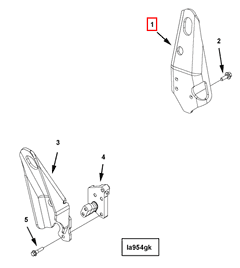

The Cummins 2883158 Lifting Bracket is a specialized component designed for use in commercial truck maintenance and operation. Its purpose is to facilitate the safe and efficient lifting and securing of heavy components during maintenance or repair procedures. This part is integral to ensuring that maintenance tasks are performed with precision and safety, contributing to the overall reliability and performance of commercial trucks.

Purpose and Functionality

The Cummins 2883158 Lifting Bracket plays a role in the operation of a commercial truck by providing a secure point for lifting heavy components. It is used during maintenance or repair procedures to ensure that parts are lifted and held in place safely. This bracket allows mechanics to work on components that would otherwise be difficult to access, enhancing the efficiency and safety of maintenance operations 1.

Key Features

The primary features of the Cummins 2883158 Lifting Bracket include its robust design and high-quality material composition. The bracket is typically made from durable materials such as steel, which provide strength and longevity. Its design includes features that enhance performance and durability, such as reinforced attachment points and a corrosion-resistant finish. These attributes ensure that the bracket can withstand the rigors of frequent use in a commercial setting 2.

Benefits

The Cummins 2883158 Lifting Bracket offers several advantages. It improves safety during lifting operations by providing a secure attachment point for heavy components. This reduces the risk of accidents and injuries. Additionally, the bracket enhances stability during maintenance tasks, allowing mechanics to work more efficiently. The use of this bracket can also lead to time savings, as it streamlines the process of lifting and securing components 3.

Installation Process

Proper installation of the Cummins 2883158 Lifting Bracket involves several steps. First, ensure that the truck is parked on a level surface and the engine is turned off. Use appropriate tools, such as wrenches and bolts, to attach the bracket to the designated mounting points on the truck. Follow the manufacturer’s guidelines for torque specifications to ensure a secure fit. Safety precautions, such as wearing protective gear and ensuring the work area is clear of obstacles, should be observed throughout the installation process 4.

Troubleshooting Common Issues

Frequent problems with the Cummins 2883158 Lifting Bracket may include loose connections or corrosion. To address these issues, regularly inspect the bracket for signs of wear or damage. Tighten any loose bolts and clean the bracket to remove any corrosion. If significant damage is detected, consider repairing or replacing the bracket to maintain optimal performance.

Maintenance Guidelines

Regular maintenance of the Cummins 2883158 Lifting Bracket is important to ensure its continued effectiveness. Inspection routines should include checking for loose bolts, signs of corrosion, and any physical damage. Cleaning the bracket with a suitable cleaner and applying a corrosion-resistant coating can help prolong its lifespan. Replacement or repair should be considered if the bracket shows significant wear or if it no longer provides a secure attachment point.

Safety Considerations

When using the Cummins 2883158 Lifting Bracket, it is important to follow safety protocols. This includes proper training on the use of the bracket and adherence to manufacturer guidelines. Ensure that all personnel involved in maintenance tasks are familiar with the bracket’s features and limitations. Regular safety audits and updates to training materials can help maintain a high standard of safety in the workplace.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is committed to innovation and excellence in the automotive and heavy-duty truck industries. The company’s product range includes a variety of components and systems designed to enhance the performance, efficiency, and reliability of commercial vehicles.

Cummins Lifting Bracket 2883158 Compatibility

The Cummins Lifting Bracket part number 2883158 is designed to be compatible with a range of Cummins engines, ensuring secure and efficient lifting operations during maintenance and repair procedures. This bracket is engineered to fit seamlessly with the following engine models:

- ISX12 CM2350 X102

- ISX12 G CM2180 EJ

- ISX12/ISX11.9 CM2250

- QSX11.9 CM2250 ECF

These engines, while varying in their specific configurations and applications, share common structural elements that allow the 2883158 Lifting Bracket to be effectively utilized across the board. The bracket’s design accommodates the unique mounting points and load requirements of these engines, facilitating safe and reliable lifting operations.

Role of Part 2883158 Lifting Bracket in Engine Systems

The Part 2883158 Lifting Bracket is a key component in the arrangement and lifting processes of engine systems. It facilitates the secure attachment of lifting equipment to the engine, ensuring stability and safety during transportation or installation.

In the context of engine arrangement, the Lifting Bracket provides a robust connection point for hoists or cranes, allowing for precise positioning of the engine within its designated space. This is particularly important in environments where space is limited, and accurate placement is required to ensure optimal performance and safety.

During the lifting process, the Lifting Bracket distributes the engine’s weight evenly, reducing the risk of structural damage to both the engine and the lifting equipment. This even weight distribution is vital for maintaining the integrity of the engine components, preventing misalignment or stress that could lead to future operational issues.

Additionally, the Lifting Bracket plays a role in simplifying the installation process by providing a secure point for attachment, which can significantly reduce the time and labor required for engine setup. This efficiency is beneficial in both manufacturing and maintenance scenarios, where minimizing downtime is a priority.

Conclusion

In summary, the Cummins 2883158 Lifting Bracket is a critical component in the safe and efficient handling of engine systems, contributing to both the arrangement and lifting processes with its reliable and sturdy design. Regular maintenance and adherence to safety protocols are essential to ensure the continued effectiveness and safety of this part in commercial truck operations.

-

Fischer, R., Kucukay, F., Jurgens, G., Najork, R., & Pollak, B. (2015). The Automotive Transmission Book Powertrain. Springer.

↩ -

Randall, M. (2015). Haynes Manual on Diesel Engines. Haynes Publishing.

↩ -

Caines, A. J., Haycock, R. F., & Hillier, J. E. (2004). Automotive Lubricants Reference Book. SAE International.

↩ -

Aird, F. (2001). Bosch Fuel Injection Systems. HP Books.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.