This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3000271 Switch Bracket is a component designed for use in commercial trucks. It serves a specific role in the vehicle’s electrical system by providing a secure mounting point for switches. This bracket ensures that switches are properly positioned and maintained, contributing to the overall functionality and safety of the truck’s electrical operations.

Purpose and Function

The primary purpose of the 3000271 Switch Bracket is to facilitate the mounting and secure placement of switches within the truck’s electrical system. By providing a stable and organized platform for switches, it ensures that they are easily accessible for operation and maintenance. This bracket plays a role in maintaining the integrity of the electrical connections, which is vital for the reliable performance of the truck’s electrical components 1.

Key Features

The 3000271 Switch Bracket is characterized by several key features that enhance its performance and reliability. It is constructed from durable materials to withstand the rigors of commercial truck environments. The bracket is designed to be compatible with various switch types, offering versatility in application. Its design allows for easy installation, reducing the time and effort required during setup. Additionally, the bracket may include unique attributes such as corrosion resistance or vibration damping features that further contribute to its durability and functionality 2.

Benefits

Utilizing the 3000271 Switch Bracket offers several benefits. It improves switch accessibility, making it easier for operators to interact with the electrical system. The bracket contributes to enhanced organization within the electrical system, reducing the likelihood of wiring issues. Its durable construction increases the longevity of the switch mounting solution, leading to reduced maintenance needs. These benefits collectively contribute to improved truck performance and maintenance efficiency 3.

Installation Process

Installing the 3000271 Switch Bracket involves several steps to ensure a proper and secure setup. Begin by identifying the appropriate location for the bracket within the truck’s electrical system. Use the necessary tools to mount the bracket securely, following the manufacturer’s guidelines for torque specifications. Connect the switches to the bracket, ensuring all electrical connections are secure and properly insulated. Finally, perform a functionality check to confirm that the switches operate correctly and that the bracket is securely installed.

Troubleshooting and Maintenance

Common issues with the 3000271 Switch Bracket may include loose connections or damage to the bracket itself. To address these issues, first, ensure that all mounting screws are tightened to the specified torque. Inspect the bracket for signs of wear or damage, and replace it if necessary. Regular maintenance involves checking the condition of the bracket and switches, ensuring that all connections remain secure and free from corrosion. Conducting periodic inspections can help identify potential issues before they lead to more significant problems.

Compatibility and Applications

The 3000271 Switch Bracket is designed for use in various commercial truck settings, including long-haul, construction, and fleet operations. It is compatible with a range of truck models and electrical systems, making it a versatile component for many applications. Its design and construction are tailored to meet the demands of these environments, ensuring reliable performance across different types of commercial trucks.

Safety Considerations

When installing and maintaining the 3000271 Switch Bracket, it is important to observe several safety considerations. Ensure that the electrical system is de-energized before beginning any work to prevent the risk of electric shock. Use the appropriate personal protective equipment, such as gloves and safety glasses, to protect against potential hazards. Follow all manufacturer guidelines and best practices to ensure the safety of mechanics and truck operators during installation and maintenance procedures.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its commitment to innovation and quality. The company offers a wide range of products, including engines, powertrains, and components, designed to meet the needs of various commercial applications. Cummins’ reputation for reliability and performance is built on a history of technological advancement and a dedication to customer satisfaction. The 3000271 Switch Bracket is part of Cummins’ extensive product line, reflecting the company’s ongoing efforts to provide high-quality solutions for the commercial truck market.

Role of Part 3000271 Switch Bracket in Engine Systems

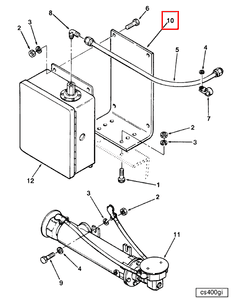

The part 3000271 Switch Bracket is an essential component in the integration and operation of various engine systems, particularly those involving starting aids and coolant heaters. This bracket facilitates the secure mounting of switches and pressure sensors, ensuring reliable performance and safety of the engine systems.

Integration with Coolant Heater Systems

In coolant heater systems, the Switch Bracket is used to mount the press switch, which is integral to the operation of the coolant heater. This setup is commonly found in systems like the Kim Hot Start 460V.4000 W, Kim Hotstart 460V 8000 W, and Kim Hotstart 460V.2500 W. The bracket ensures that the press switch is correctly positioned to monitor the pressure within the coolant system, allowing for precise control over the heating process. This is vital for maintaining optimal engine temperature during cold starts, enhancing engine performance and longevity.

Hydraulic Starting Aid Systems

For hydraulic starting aid systems, the Switch Bracket plays a significant role in the mounting of switches that activate the hydraulic components. These systems often include accessories that require precise switch activation to ensure the hydraulic components engage at the correct time during the starting sequence. The bracket’s robust design ensures that these switches remain securely in place, even under the vibrations and stresses typical of engine operation.

Cold Start Aid Systems

In cold start aid systems, the Switch Bracket is employed to mount switches that control the activation of various heating elements, such as the engine coolant heater or water heater. These systems are designed to preheat the engine coolant or other fluids to facilitate easier starting in cold conditions. The bracket ensures that the switches are reliably mounted, allowing for consistent and safe operation of the cold start aids.

Pressure Switch Mounting

The Switch Bracket is also utilized in pressure switch mounting applications. In these scenarios, it secures pressure switches that monitor the pressure levels within the engine’s coolant or hydraulic systems. Accurate pressure monitoring is essential for the safe and efficient operation of these systems, preventing issues such as overheating or hydraulic failure.

To B Rail MTG

In applications where the switch needs to be mounted to the B rail, the Switch Bracket provides a stable and secure attachment point. This is particularly important in systems where the B rail is subjected to significant stress or vibration, ensuring that the switch remains operational and accurately positioned.

Overall System Reliability

By providing a stable and secure mounting solution for switches and pressure sensors, the part 3000271 Switch Bracket contributes to the overall reliability and performance of engine systems. Its role in ensuring that these components are correctly positioned and remain operational under various conditions is fundamental to the efficient and safe operation of modern engine systems.

Conclusion

The Cummins 3000271 Switch Bracket is a critical component in the electrical systems of commercial trucks, ensuring the secure and reliable mounting of switches and pressure sensors. Its durable construction, ease of installation, and compatibility with various truck models make it a versatile and essential part for maintaining the functionality and safety of truck electrical systems. Regular maintenance and adherence to safety guidelines are crucial for maximizing the benefits of this Cummins part.

-

Shashank Arora, Alireza Tashakori Abkenar, and Shantha Gamini Jayasi, Heavyduty Electric Vehicles: From Concept to Reality (Elsevier, 2021).

↩ -

Sean Bennett, Modern Diesel Technology: Light Duty Diesels (Cengage Learning, 2012).

↩ -

Robert Fischer, Ferit Kucukay, Gunter Jurgens, Rolf Najork, and Burkhard Pollak, The Automotive Transmission Book Powertrain (Springer, 2015).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.