This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

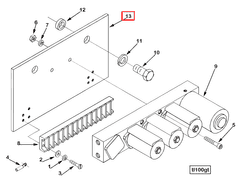

The Bracket, Solenoid Mounting (Part #3007703) manufactured by Cummins is a component designed for use in commercial trucks. This Cummins part plays a role in securing the solenoid, which is integral to the operation of various truck systems. Proper solenoid mounting is important for the reliable functioning of electrical components in truck operations.

Function and Operation

The Solenoid Mounting Bracket functions within the truck’s electrical system by providing a stable platform for the solenoid. The solenoid itself is responsible for controlling the flow of electricity to different components, such as the starter motor or fuel injectors. The bracket ensures that the solenoid is correctly positioned and securely held in place, which is necessary for the consistent and reliable operation of these components 1.

Key Features

This part is constructed from durable materials, typically a corrosion-resistant metal alloy, which enhances its longevity in the demanding environment of a commercial truck. Its design includes features such as pre-drilled holes and mounting tabs that align with standard solenoid dimensions, facilitating straightforward installation. Additionally, the bracket may incorporate vibration dampening elements to reduce the impact of road vibrations on the solenoid’s performance 2.

Benefits of Using the 3007703 Bracket

Utilizing the 3007703 Solenoid Mounting Bracket offers several advantages. Its robust construction contributes to the reliability of the solenoid’s operation, which in turn supports the overall efficiency of the truck’s electrical system. The bracket’s design allows for ease of installation, reducing downtime during maintenance procedures. Furthermore, by ensuring the solenoid is securely mounted, the bracket helps maintain the integrity of the electrical connections, which is vital for the consistent performance of truck components 3.

Installation Process

Installing the Solenoid Mounting Bracket involves several steps to ensure it is correctly and safely secured. First, the area where the bracket will be mounted should be cleaned to remove any debris. The bracket is then aligned with the solenoid and the truck’s chassis, using the pre-drilled holes as a guide. Fasteners are inserted through these holes and tightened to secure the bracket in place. It is important to follow the manufacturer’s torque specifications to avoid over-tightening, which could damage the bracket or solenoid 4.

Maintenance and Troubleshooting

To maintain the Solenoid Mounting Bracket and ensure its longevity, regular inspections should be conducted to check for signs of corrosion, wear, or loose fasteners. If any issues are detected, they should be addressed promptly to prevent further damage. Common problems may include solenoid malfunction due to a loose mount, which can be rectified by re-securing the bracket. Additionally, ensuring that the electrical connections remain clean and free from corrosion will help maintain the solenoid’s performance.

Compatibility and Applications

The 3007703 Solenoid Mounting Bracket is designed for use with specific types of trucks and engine models. It is applicable in various commercial truck settings where reliable solenoid operation is required. The bracket’s design allows it to be compatible with a range of solenoids used in these applications, making it a versatile component for truck maintenance and upgrade procedures.

Cummins: A Brief Overview

Cummins Inc. is a well-established manufacturer in the commercial truck industry, known for its wide range of engine and component products. The company has a history of innovation and commitment to quality, which is reflected in its product offerings. Cummins’ reputation is built on its ability to deliver reliable and high-performance components that meet the rigorous demands of commercial trucking operations.

Role of Part 3007703 Bracket, Solenoid mtg. in Engine Systems

The Part 3007703 Bracket, Solenoid mtg. is an integral component in the orchestration of several engine systems, ensuring precise and efficient operation. This bracket is specifically designed to secure the solenoid, which plays a significant role in the modulation of engine functions.

In the context of mounting maintenance, the bracket provides a stable and secure platform for the solenoid. This stability is essential for the consistent performance of the solenoid, which in turn affects the overall reliability of the engine system.

When integrated with a multi-unit throttle control (MUTC) system, the bracket facilitates the accurate positioning of the solenoid. This precise placement allows for the solenoid to effectively communicate with the throttle control unit, ensuring that the throttle plate responds appropriately to commands. The MUTC system relies on this interaction to maintain optimal air-fuel ratios, which are vital for engine efficiency and performance.

The bracket also plays a role in the solenoid mounting valve system. By providing a firm attachment point, it ensures that the valve can operate without undue stress or movement. This is particularly important in high-stress environments where vibrations and thermal expansion could otherwise compromise the valve’s function.

Conclusion

In summary, the Part 3007703 Bracket, Solenoid mtg. is a foundational element in the effective operation of solenoid-based systems within engine components. Its role in securing and stabilizing the solenoid ensures that critical functions such as throttle control and valve operation are performed with precision and reliability.

-

Bonneau, D., Fatu, A., & Souchet, D. (2014). Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings. Wiley-ISTE.

↩ -

Reif, K. (Ed.). (2014). Diesel Engine Management Systems and Components. Springer Vieweg.

↩ -

Drozdziel, P. (2023). The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects. Routledge.

↩ -

Lakshminarayanan, P. A., & Agarwal, A. K. (2019). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.