This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

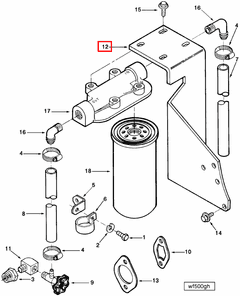

The Corrosion Resistor Bracket, part number 3009379, manufactured by Cummins, is a component designed for use in commercial truck applications. Cummins, a well-established name in the automotive industry, is known for its robust and reliable parts. This bracket is particularly significant in environments where corrosion resistance is paramount, ensuring the longevity and reliability of truck components.

Purpose and Function

The Corrosion Resistor Bracket plays a role in supporting and securing various components within a truck’s engine system. It is typically positioned in areas exposed to moisture and other corrosive elements. By providing a stable mounting point, it ensures that connected parts remain firmly in place, which is vital for the proper operation of the truck. Its interaction with other components helps maintain the structural integrity and efficiency of the engine system.

Key Features

This Cummins part is constructed from materials specifically chosen for their resistance to corrosion. Common materials include stainless steel or coated metals that offer enhanced durability in harsh environments. The design of the bracket includes features such as reinforced edges and precise mounting points to ensure a secure fit. Additionally, the bracket may incorporate unique characteristics like anti-corrosive coatings or specialized alloys that further enhance its performance.

Benefits

One of the primary advantages of the Corrosion Resistor Bracket is its improved durability. The materials and design elements work together to resist corrosion, which can extend the lifespan of the bracket and the components it supports. This resistance to environmental factors contributes to the overall reliability of the truck, reducing the need for frequent replacements or repairs. Furthermore, the bracket’s robust construction helps maintain the structural integrity of the engine system, ensuring consistent performance 1.

Installation Process

Installing the Corrosion Resistor Bracket involves several steps to ensure proper placement and function. Begin by identifying the correct location for the bracket within the engine system. Use the provided mounting hardware to secure the bracket in place, ensuring that all connections are tight and stable. It is important to follow the manufacturer’s guidelines for torque specifications to avoid over-tightening, which could damage the bracket or surrounding components. After installation, perform a visual inspection to confirm that the bracket is correctly positioned and that all connected parts are secure.

Maintenance and Troubleshooting

To maintain the Corrosion Resistor Bracket, regular inspections are recommended to check for signs of wear or corrosion. Cleaning the bracket with a mild detergent and water can help remove any buildup that may accelerate corrosion. If corrosion is detected, applying a protective coating can help restore the bracket’s resistance to environmental factors. Common issues include loose connections or damage to the bracket, which can often be addressed by re-tightening hardware or replacing damaged parts. Following these maintenance practices can help ensure the longevity and optimal performance of the bracket 2.

Environmental and Operational Considerations

Environmental conditions and operational factors can significantly influence the performance and lifespan of the Corrosion Resistor Bracket. Exposure to moisture, salt, and other corrosive elements can accelerate wear and corrosion. Regular maintenance and inspections are crucial in environments where these factors are prevalent. Additionally, operational factors such as vibration and temperature fluctuations can impact the bracket’s stability and integrity. Understanding these influences allows for better maintenance practices and prolongs the bracket’s service life 3.

Cummins Overview

Cummins is a renowned manufacturer in the commercial truck industry, with a history of producing high-quality, reliable parts. The company offers a wide range of products designed to meet the demanding requirements of commercial vehicles. Cummins’ reputation for durability and performance is built on a commitment to innovation and excellence. The Corrosion Resistor Bracket, part number 3009379, is just one example of Cummins’ dedication to providing components that enhance the reliability and efficiency of commercial trucks.

Cummins Corrosion Resistor Bracket 3009379 in Engine Applications

The Cummins Corrosion Resistor Bracket, part number 3009379, is a critical component in maintaining the structural integrity and longevity of various engine systems. This part is designed to mitigate the effects of corrosion, a common issue in engine environments due to exposure to moisture, chemicals, and other corrosive agents.

V28 Engine Series

In the V28 engine series, the Corrosion Resistor Bracket 3009379 is strategically placed to protect key engine components from corrosion. This bracket is typically used in conjunction with other mounting and support structures to ensure that the engine remains stable and operational under various conditions. Its placement is crucial in areas where corrosion can lead to significant damage, such as around exhaust manifolds, coolant passages, and other vulnerable spots.

The bracket’s design ensures that it can withstand the stresses and strains of engine operation while providing a robust barrier against corrosive elements. This is particularly important in heavy-duty applications where the engine is exposed to harsh environments, such as marine or industrial settings.

Integration with Engine Systems

The integration of the Corrosion Resistor Bracket 3009379 into the engine system is a meticulous process that involves precise alignment and secure fastening. This part is engineered to fit seamlessly with other components, ensuring that it does not interfere with the engine’s performance or maintenance procedures. The bracket’s material and construction are chosen to provide maximum resistance to corrosion, ensuring that it can perform reliably over the engine’s operational life.

Compatibility and Usage

The Cummins Corrosion Resistor Bracket 3009379 is designed to be compatible with a range of engine configurations within the V28 series. Its versatility allows it to be used in various applications, providing a consistent level of protection across different engine models. This compatibility is essential for maintaining uniformity in engine maintenance and repair processes, making it easier for technicians to service and replace parts as needed.

Overall, the Corrosion Resistor Bracket 3009379 plays a vital role in the longevity and reliability of the V28 engine series, ensuring that critical components remain protected from the damaging effects of corrosion.

Role of Part 3009379 Corrosion Resistor Bracket in Engine Systems

The part 3009379 Corrosion Resistor Bracket is integral to the efficient and reliable operation of various engine systems. This component is designed to enhance the durability and performance of the engine by providing a robust mounting solution that resists corrosion.

Integration with Fuel Plumbing

In fuel systems, the Corrosion Resistor Bracket secures fuel lines and components, ensuring they remain firmly in place despite the corrosive nature of fuel. This stability is essential for maintaining the integrity of the fuel plumbing, preventing leaks, and ensuring consistent fuel delivery to the engine.

Support for Resistors

When used with electrical systems, the bracket provides a secure mounting point for resistors. This is particularly important in high-temperature environments where resistors can be susceptible to damage. The corrosion-resistant properties of the bracket ensure that the resistors remain protected and functional over extended periods.

Enhancing Corrosion Resistance

The primary function of the Corrosion Resistor Bracket is to offer superior protection against corrosion. In marine or industrial applications where engines are exposed to harsh environments, this bracket helps prolong the lifespan of attached components by preventing rust and degradation. This is achieved through its material composition and design, which are tailored to withstand corrosive agents.

Application in Various Engine Components

Across different engine systems, the bracket plays a supportive role by ensuring that critical components are securely mounted. Whether it is securing sensors, actuators, or other auxiliary parts, the bracket’s corrosion-resistant features contribute to the overall reliability and performance of the engine.

By providing a stable and durable mounting solution, the part 3009379 Corrosion Resistor Bracket enhances the functionality and longevity of engine systems, making it a valuable component in both maintenance and upgrade scenarios.

Conclusion

The Corrosion Resistor Bracket, part number 3009379, is a critical component in the maintenance and reliability of commercial truck engines. Its design and material composition provide superior resistance to corrosion, ensuring the longevity and performance of engine components. Proper installation, regular maintenance, and understanding environmental and operational factors are essential for maximizing the benefits of this Cummins part. By integrating this bracket into engine systems, Cummins continues to demonstrate its commitment to innovation and excellence in the commercial truck industry.

-

Vehicle Crash Dynamics, Matthew Huang, CRC Press, 2002

↩ -

Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition, John Dixon, Cengage Learning, 2014

↩ -

Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems, Konrad Reif, Springer Vieweg, 2014

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.