This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Control Linkage Bracket 3010999, manufactured by Cummins, is a component designed for use in commercial trucks. Its purpose is to facilitate the connection and movement between various parts of the truck’s control system, ensuring that commands from the driver are accurately transmitted to the vehicle’s mechanical systems. Cummins, a well-established name in the industry, is known for producing reliable and high-performance parts that contribute to the efficient operation of commercial vehicles 1.

Function and Operation

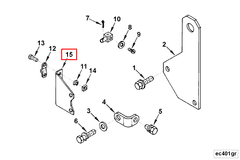

The Control Linkage Bracket 3010999 operates by providing a stable and secure mounting point for the linkage components within the truck’s control system. It interacts with other components such as the throttle lever, governor, and accelerator pedal, playing a role in the precise transmission of driver inputs to the engine’s fuel system. This ensures that the vehicle responds accurately to driver commands, contributing to smooth and controlled operation 2.

Key Features

The Control Linkage Bracket 3010999 is constructed from durable materials, typically a combination of high-strength steel and corrosion-resistant coatings, which enhance its longevity and performance in demanding environments. Its design includes features such as reinforced mounting points and precise machining to ensure a snug fit and reliable operation. Additionally, the bracket may incorporate unique attributes such as vibration dampening elements to reduce wear and tear on connected components 3.

Benefits

The advantages of using the Control Linkage Bracket 3010999 include improved durability due to its robust material composition, enhanced performance through precise engineering, and reliability under various operating conditions. These attributes contribute to the overall efficiency and longevity of the truck’s control system, reducing the likelihood of malfunctions and the need for frequent repairs.

Installation Process

To install the Control Linkage Bracket 3010999, begin by ensuring the truck is securely supported and the engine is off. Gather the necessary tools, which may include wrenches, sockets, and possibly a torque wrench. Follow the manufacturer’s instructions for removing the old bracket, if applicable, and carefully position the new bracket in its designated location. Secure it with the provided fasteners, ensuring they are tightened to the specified torque settings to avoid over-tightening or under-tightening, which could affect performance.

Maintenance Tips

Regular maintenance of the Control Linkage Bracket 3010999 involves periodic inspection for signs of wear, corrosion, or damage. Cleaning the bracket and its surrounding components can prevent the buildup of dirt and debris that may interfere with its operation. It is also important to lubricate moving parts as recommended by the manufacturer to ensure smooth function. Replacement should be considered if significant wear is observed or if the bracket no longer secures the linkage components effectively.

Troubleshooting Common Issues

Common problems with the Control Linkage Bracket 3010999 may include loose connections, wear on mounting points, or corrosion. Symptoms of these issues can manifest as erratic engine performance or difficulty in controlling the vehicle’s speed. To address these problems, inspect the bracket and its connections for signs of wear or corrosion. Tighten any loose fasteners and clean or replace corroded components as necessary. If wear is significant, replacement of the bracket may be required.

Safety Considerations

When working with the Control Linkage Bracket 3010999, it is important to follow safety guidelines to prevent injury and ensure the correct operation of the vehicle. This includes wearing appropriate personal protective equipment, ensuring the vehicle is securely supported before beginning work, and following all manufacturer recommendations for installation and maintenance. Additionally, be aware of the potential for moving parts within the control system and take precautions to avoid contact with them while the engine is running.

Cummins Overview

Cummins is a leading manufacturer in the commercial truck industry, with a history of innovation and quality production. The company offers a wide range of products, including engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial transportation. Cummins’ reputation for reliability and performance makes its parts, like the Control Linkage Bracket 3010999, a popular choice among fleet operators and maintenance professionals.

Cummins Control Linkage Bracket 3010999 Compatibility

The Cummins Control Linkage Bracket, part number 3010999, is designed to be compatible with a range of Cummins engines, including the K19 and K50 series. This bracket plays a role in the engine’s operation by ensuring the control linkage is properly mounted and aligned, which is important for the smooth functioning of the engine’s control systems.

For the K19 engines, the 3010999 bracket is engineered to fit seamlessly, providing a robust connection point for the control linkage. This ensures that the engine’s control mechanisms are effectively managed, contributing to the overall performance and reliability of the K19 engine.

Similarly, the K50 engines benefit from the precise fit and construction of the 3010999 bracket. This part ensures that the control linkage is securely attached, which is important for the K50 engines’ operational integrity. The bracket’s design allows for easy installation and maintenance, making it a reliable choice for these engines.

In both engine series, the 3010999 bracket is crafted from high-quality materials to withstand the rigors of engine operation. Its compatibility with both the K19 and K50 engines underscores Cummins’ commitment to providing parts that meet the highest standards of durability and performance.

Role of Part 3010999 Control Linkage Bracket in Engine Systems

The Part 3010999 Control Linkage Bracket is an integral component in the orchestration of various engine systems, ensuring precise and responsive control over engine functions. This bracket plays a role in the assembly and operation of several key components, facilitating smooth and efficient engine performance.

Integration with the American Bosch Governor

In systems utilizing the American Bosch Governor, the Control Linkage Bracket serves as a pivotal connection point. It secures the governor’s linkage to the engine, allowing for accurate modulation of engine speed in response to load changes. This ensures the governor can effectively manage the engine’s RPM, contributing to stable and efficient operation.

Connection to the Cable Clamp Bracket

The Control Linkage Bracket interfaces with the Cable Clamp Bracket to maintain the integrity of the throttle control system. By providing a stable mounting point, it ensures that the cable clamp can adjust the throttle position with precision, directly influencing the engine’s power output and responsiveness.

Role in the Delay Cylinder Mechanism

When integrated with the Delay Cylinder, the Control Linkage Bracket aids in the gradual adjustment of engine components. This is particularly important in systems where a delayed response is required, such as in certain fuel injection systems, allowing for smoother transitions and reduced wear on engine parts.

Interaction with the Fuel Pump

In fuel pump systems, the Control Linkage Bracket helps in the accurate positioning and operation of the fuel pump lever. This ensures that the fuel pump delivers the correct amount of fuel to the engine, optimizing combustion efficiency and overall engine performance.

Mounting and Stability

The Control Linkage Bracket provides essential mounting points for various engine components, including the Throttle Control and Throttle Lever. Its robust design ensures that these components remain securely in place, even under the dynamic conditions of engine operation, thereby enhancing the reliability and durability of the engine system.

Enhancing Vernier Throttle Control

For engines equipped with Vernier Throttle Control, the Control Linkage Bracket is vital in allowing fine adjustments to the throttle position. This precision control is essential for applications requiring exact throttle settings, such as in aviation or marine engines, where even minor adjustments can significantly impact performance.

In summary, the Part 3010999 Control Linkage Bracket is a fundamental component in the coordination and operation of various engine systems. Its role in connecting, stabilizing, and facilitating the precise adjustment of engine components underscores its importance in achieving optimal engine performance and reliability.

Conclusion

The Control Linkage Bracket 3010999 by Cummins is a critical component in the operation of commercial truck engines, ensuring precise and responsive control over engine functions. Its robust design, compatibility with various Cummins engines, and role in integrating key engine systems highlight its importance in achieving optimal engine performance and reliability. Regular maintenance and proper installation are essential to maximize the benefits of this Cummins part.

-

Bonnick, A. (2004). A Practical Approach to Motor Vehicle Engineering and Maintenance. Elsevier.

↩ -

Asef, P., Padmanaban, S., & Lapthorn, A. (2022). Modern Automotive Electrical Systems. Wiley.

↩ -

Goodnight, N., & VanGelder, K. (2019). Automotive Braking Systems CDX Master Automotive Technician Series. Jones Bartlett Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.