This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

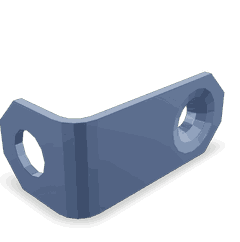

Introduction to Noise Panel Brackets

Noise panel brackets are essential components in commercial truck engines, designed to manage and reduce noise levels. These brackets support noise panels, which are typically made of acoustic materials, to dampen sound produced by the engine and its components. Effective noise management is crucial for maintaining a comfortable and safe environment for drivers and passengers, as well as for meeting regulatory standards 1.

The Role of the Cummins Noise Panel Bracket

The Cummins Noise Panel Bracket, identified as part #3013107, is specifically engineered to support noise panels in Cummins engines. This bracket ensures that the noise panels are securely attached and properly positioned to maximize their acoustic performance. By doing so, it helps in reducing the overall noise output of the engine, contributing to a quieter cabin environment 2.

How the Cummins Noise Panel Bracket Works

The Cummins Noise Panel Bracket works by providing a stable mounting point for noise panels. These panels are often made from materials such as fiberglass, foam, or other sound-absorbing substances. The bracket is typically bolted to the engine block or other structural components, ensuring that the noise panels are held in place under all operating conditions. The design of the bracket is critical to its function, as it must withstand the vibrations and stresses of engine operation while maintaining the integrity of the noise panel attachment 3.

Importance in Truck Operations

In commercial truck operations, maintaining a quiet and comfortable cabin is essential for driver comfort and safety. Excessive noise can lead to driver fatigue, which can negatively impact performance and increase the risk of accidents. The Cummins Noise Panel Bracket plays a vital role in achieving these goals by ensuring that noise levels are kept within acceptable limits. This is particularly important for long-haul drivers who spend extended periods in the cab.

Troubleshooting and Maintenance

Proper maintenance of the Cummins Noise Panel Bracket is crucial for ensuring its effectiveness over time. Regular inspections should be conducted to check for any signs of wear, corrosion, or damage to the bracket or its mounting points. If any issues are detected, the bracket should be repaired or replaced as necessary to maintain optimal performance.

In terms of troubleshooting, if noise levels increase unexpectedly, it may indicate that the noise panels have shifted or become damaged. Inspecting the bracket and noise panels for proper attachment and integrity is the first step in addressing such issues. Ensuring that all bolts and fasteners are tight and that the noise panels are not damaged or degraded will help maintain the bracket’s effectiveness.

Cummins: A Leader in Engine Technology

Cummins is a renowned manufacturer of heavy-duty engines and related components, known for its innovation and quality. The company has a long history of developing advanced engine technologies that meet the demanding needs of commercial truck operators. The Cummins Noise Panel Bracket is a testament to the company’s commitment to providing reliable and effective solutions for noise management in commercial truck engines.

Expert Insights and Best Practices

To ensure the longevity and effectiveness of the Cummins Noise Panel Bracket, it is important to follow best practices for installation and maintenance. This includes using the correct fasteners and ensuring that all components are properly aligned during installation. Additionally, regular maintenance checks can help identify potential issues before they become significant problems.

By understanding the role and function of the Cummins Noise Panel Bracket, commercial truck operators and maintenance professionals can better appreciate its importance in maintaining a quiet and comfortable cabin environment. Proper installation, regular maintenance, and timely troubleshooting are key to maximizing the performance of this critical component.

Compatibility with Cummins Engines

The Noise Panel Bracket, identified by the part number 3013107, is a crucial component designed to secure and support noise panels in various Cummins engine models. This part ensures that the noise panels are properly aligned and fastened, contributing to the overall noise reduction and operational efficiency of the engines.

ISM Series Engines

- ISM CM570

- ISM CM570/870

The Noise Panel Bracket is compatible with the ISM CM570 and ISM CM570/870 engines, providing a secure mounting point for the noise panels. This ensures that the noise levels are kept within acceptable limits, enhancing the operational environment.

L10 Series Engines

- L10 CELECT

- L10 GAS

- L10 MECHANICAL

For the L10 series, which includes the CELECT, GAS, and MECHANICAL variants, the Noise Panel Bracket is designed to fit seamlessly. This compatibility is essential for maintaining the structural integrity and noise reduction capabilities of these engines.

M11 Series Engines

- M11 CELECT

- M11 CELECT PLUS

The Noise Panel Bracket is also suitable for the M11 CELECT and M11 CELECT PLUS engines. This ensures that the noise panels are correctly positioned, contributing to the overall performance and noise management of these engines.

N14 Series Engines

- N14 CELECT

- N14 CELECT PLUS

- N14 MECHANICAL

The N14 series, including the CELECT, CELECT PLUS, and MECHANICAL engines, are also compatible with the Noise Panel Bracket. This compatibility is vital for maintaining the noise reduction standards and operational efficiency of these engines.

NH/NT 855

The Noise Panel Bracket is designed to fit the NH/NT 855 engine, ensuring that the noise panels are securely mounted and contributing to the engine’s noise management system.

QSM11 CM570

Lastly, the Noise Panel Bracket is compatible with the QSM11 CM570 engine, providing a reliable mounting solution for the noise panels. This ensures that the engine operates within the desired noise levels, enhancing its performance and reliability.

Role of Part 3013107 Noise Panel Bracket in Engine Systems

The Part 3013107 Noise Panel Bracket is an essential component in the assembly and integration of various engine systems. It provides a stable mounting platform for the noise control panel, which is designed to reduce the acoustic emissions from the engine. This bracket ensures that the noise control panel is securely fastened and properly aligned with other components.

Integration with Engine Components

-

Cylinder Block and Engine Cover: The Noise Panel Bracket is typically mounted on the engine cover, which is attached to the cylinder block. This positioning allows the bracket to support the noise control panel directly over the noisiest parts of the engine, effectively dampening sound.

-

Breather and Valve Cover: The bracket often interfaces with the breather and valve cover system. It may be positioned to allow easy access to the breather mounting tube and breather tube mounting points, ensuring that the ventilation system operates efficiently without interference from the noise control panel.

-

Turbocharger and Plumbing: In turbocharged engines, the Noise Panel Bracket must be carefully positioned to avoid obstructing the turbocharger plumbing. It ensures that the turbocharger can be mounted and connected without conflict, maintaining optimal performance and reliability.

-

Wiring and Harnesses: The bracket plays a role in the arrangement and protection of wiring harnesses. It may provide mounting points for the pacer wire harness and other electrical components, ensuring that wires are neatly organized and shielded from engine heat and vibration.

-

Accessories and Control Systems: The Noise Panel Bracket can also support various accessories and control systems. For instance, it may hold the pacer control unit or components of the pressure-time pacer conversion kit, ensuring these systems are securely mounted and function correctly.

-

Cable and Control Mounting: Additionally, the bracket can be used to mount cables and control linkages, such as those for the turbocharger or other engine controls. This helps in maintaining a clean and organized engine bay, reducing the risk of cable damage or interference.

Noise Reduction and System Efficiency

By providing a robust mounting solution for the noise control panel, the Part 3013107 Noise Panel Bracket contributes to the overall noise reduction strategy of the engine system. It ensures that the panel is effectively positioned to absorb and dissipate sound, enhancing the engine’s acoustic performance. Furthermore, its role in organizing and securing various engine components contributes to the system’s efficiency and reliability, making it a valuable part of the engine assembly.

Conclusion

The Cummins Noise Panel Bracket, part #3013107, is a critical component in the noise management system of commercial truck engines. Its role in securely mounting and aligning noise panels ensures that engine noise is effectively reduced, contributing to a quieter and more comfortable cabin environment. Proper installation, regular maintenance, and timely troubleshooting are essential to maximizing the performance and longevity of this part. By understanding and appreciating the importance of this Cummins part, operators and maintenance professionals can ensure optimal engine performance and driver comfort.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.