This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3042001 Shipping Bracket is a component designed for use in heavy-duty truck applications. Its purpose is to secure and stabilize specific parts of the truck during transportation and storage, ensuring that these components remain intact and properly positioned. This bracket is significant in the context of heavy-duty truck components as it contributes to the overall safety and efficiency of truck operations by maintaining the integrity of the parts it secures 1.

Purpose and Functionality

This Cummins part plays a role in the operation of a truck by providing a secure mounting solution for various components during transit and storage. It ensures that parts are held firmly in place, reducing the risk of damage or displacement. This functionality is vital for maintaining the condition of truck components, which is crucial for their performance and longevity once the truck is in service 2.

Key Features

The primary features of the 3042001 include its robust material composition, which is designed to withstand the rigors of transportation and storage. The bracket is crafted with precision to ensure a snug fit and secure hold on the components it is intended to support. Additionally, it may incorporate design elements such as reinforced edges or specialized mounting points to enhance its performance and reliability 3.

Benefits

The 3042001 offers several advantages. Its durable construction contributes to the longevity of the bracket, reducing the need for frequent replacements. The design of the bracket facilitates ease of installation, allowing mechanics to quickly and efficiently secure components. Furthermore, by ensuring that parts are properly secured during transportation and storage, the bracket contributes to the overall efficiency and safety of truck operations.

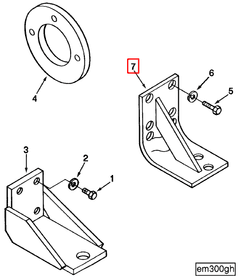

Installation Process

Installing the 3042001 involves several steps. First, the area where the bracket will be mounted should be cleaned and prepared. The bracket should then be aligned with the designated mounting points on the truck or component it is securing. Using the appropriate fasteners, the bracket is secured in place, ensuring that it is firmly attached and that the components are held securely. It is important to follow the manufacturer’s guidelines for installation to ensure proper fit and function.

Maintenance and Troubleshooting

To maintain the 3042001, regular inspections should be conducted to check for any signs of wear, damage, or loosening of the fasteners. Common issues may include corrosion or deformation of the bracket, which can compromise its effectiveness. If any issues are detected, they should be addressed promptly to prevent further damage or failure. Troubleshooting may involve tightening fasteners, applying corrosion-resistant coatings, or replacing the bracket if it is beyond repair.

Compatibility and Usage

The 3042001 is designed for use with specific types of trucks and engines. It is particularly beneficial in scenarios where components need to be securely transported or stored, such as during manufacturing, shipping, or maintenance operations. The bracket’s compatibility ensures that it can be effectively utilized across a range of heavy-duty truck applications.

Safety Considerations

When installing and maintaining the 3042001, it is important to adhere to safety protocols to ensure the well-being of mechanics and truck operators. This includes using personal protective equipment, following proper lifting techniques, and ensuring that the work area is free from hazards. Additionally, it is crucial to verify that the bracket is securely installed and that all fasteners are tightened to the manufacturer’s specifications to prevent accidents or injuries.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the automotive industry, particularly in the realm of heavy-duty truck components. The company’s product range includes a variety of parts and systems designed to enhance the performance, efficiency, and safety of trucks and other vehicles.

Cummins Engine Part 3042001: Shipping Bracket Compatibility

The Cummins part 3042001, identified as a Shipping Bracket, is designed to be compatible with a range of Cummins engines. This bracket is essential for securing and stabilizing the engine during transportation and installation processes.

V903 and VTA903 Engines

The Shipping Bracket 3042001 is specifically engineered to fit the V903 and VTA903 engines. These engines are known for their robust design and reliability, often used in heavy-duty applications. The bracket ensures that the engine remains securely in place, preventing any movement that could lead to damage during transit or installation.

CM2250 V105 Engine

Similarly, the CM2250 V105 engine is also compatible with the Shipping Bracket 3042001. This engine is part of Cummins’ lineup of medium-duty engines, providing a balance of power and efficiency. The bracket’s design allows for easy attachment and removal, facilitating the safe handling of the engine.

Grouping of Engines

The V903 and VTA903 engines, while distinct in their specific applications, share a commonality in their need for a secure mounting solution during transportation. The CM2250 V105, on the other hand, represents a different segment of Cummins’ engine offerings, yet it still benefits from the same level of secure mounting provided by the Shipping Bracket 3042001. This grouping highlights the versatility and broad applicability of the bracket across various engine models.

Role of Part 3042001 Shipping Bracket in Engine Systems

The 3042001 Shipping Bracket is an essential component in the secure transportation of engine systems. Its primary function is to ensure that the engine remains stable and undamaged during shipping.

When an engine is prepared for shipping, the cylinder block is the central component that requires secure fastening. The 3042001 Shipping Bracket is strategically positioned to interface with the cylinder block, providing a robust connection point. This bracket is part of a larger arrangement that includes multiple shipping brackets and mounting points, collectively designed to distribute the weight and secure the engine effectively.

The engine mounting system plays a significant role in this process. The shipping bracket works in conjunction with the engine mounting points to create a stable framework. This framework is vital for maintaining the integrity of the engine during transit, preventing any movement that could lead to damage.

Conclusion

In summary, the 3042001 Shipping Bracket is a key element in the shipping arrangement, ensuring that the engine, particularly the cylinder block, is securely fastened and protected throughout the shipping process. Its integration with the engine mounting system and other shipping brackets forms a comprehensive solution for safe engine transportation.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.