This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3043118 Switch Bracket is a component designed for use in commercial trucks. It serves as a mounting point for various electrical switches and controls within the vehicle’s system. A switch bracket generally functions to secure and organize switches, ensuring they are easily accessible and properly integrated into the truck’s electrical network 1.

Purpose and Function

This Cummins part is designed to facilitate the operation of multiple switches and controls in a commercial truck’s electrical system. It provides a stable platform for mounting switches, allowing for efficient and organized management of electrical components. This bracket plays a role in ensuring that switches are securely positioned and correctly wired, contributing to the reliable operation of the truck’s electrical system 2.

Key Features

The 3043118 is characterized by several key features that enhance its performance and durability. Its design is engineered to accommodate various switch sizes and types, ensuring versatility in application. The bracket is constructed from high-quality materials, which contribute to its robustness and resistance to wear and environmental factors. Additionally, it features precise mounting points and secure attachment mechanisms, which aid in the stable installation of switches 3.

Benefits

The 3043118 offers several benefits that contribute to the efficiency and reliability of commercial trucks. It provides improved electrical connectivity by ensuring switches are properly aligned and wired. The durable construction of the bracket enhances the longevity of the installed switches, reducing the need for frequent replacements. Furthermore, its design allows for ease of installation, minimizing downtime during maintenance procedures 4.

Installation Process

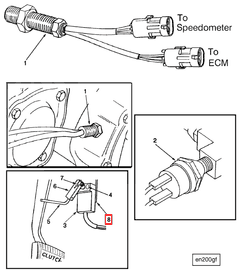

Installing the 3043118 involves several steps to ensure proper fitting and functionality. Begin by gathering the necessary tools, which may include a wrench, screwdriver, and electrical tape. Prepare the installation site by ensuring the surface is clean and free of obstructions. Align the bracket with the designated mounting points and secure it using the provided fasteners. Once the bracket is firmly in place, proceed to install the switches, ensuring they are correctly wired and connected to the truck’s electrical system.

Troubleshooting Common Issues

Common issues with the 3043118 may include electrical faults or physical damage to the bracket or switches. To address electrical faults, check the wiring connections for any loose or corroded terminals. Ensure that all switches are correctly installed and that there are no short circuits. In the case of physical damage, inspect the bracket and switches for signs of wear or breakage. Replace any damaged components as necessary to restore functionality.

Maintenance Tips

Regular maintenance of the 3043118 is important for ensuring its longevity and optimal performance. Inspect the bracket and switches periodically for signs of wear, corrosion, or damage. Clean the bracket and switches to remove any dirt or debris that may accumulate over time. If any components show signs of significant wear or malfunction, consider replacing them to maintain the reliability of the truck’s electrical system.

Compatibility and Applications

The 3043118 is designed for use in various commercial truck models. It is compatible with a range of truck configurations and electrical systems, making it a versatile component for fleet management. Its application extends to both new and existing truck models, providing a reliable solution for switch mounting and organization.

Safety Considerations

When installing or maintaining the 3043118, it is important to observe safety precautions to avoid electrical hazards. Ensure that the truck’s battery is disconnected before beginning any work on the electrical system. Use insulated tools to prevent electrical shocks. Follow all manufacturer guidelines and safety instructions to ensure a safe working environment.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its commitment to quality and innovation. The company has a long history of producing reliable and high-performance truck components, including the 3043118. Cummins’ dedication to excellence is evident in its rigorous manufacturing processes and continuous investment in research and development.

Cummins Switch Bracket 3043118 Compatibility

The Cummins Switch Bracket part number 3043118 is designed to fit seamlessly within several engine models, ensuring compatibility and reliability across different engine types. This part is integral in maintaining the operational integrity of the engines it is used in.

N14 MECHANICAL Engines

In the N14 MECHANICAL engines, the Switch Bracket 3043118 plays a role in the electrical system. It is specifically engineered to mount and secure various switches, ensuring they are positioned correctly and function without interference. This bracket is essential for maintaining the alignment and operational efficiency of the switches, which are critical for the engine’s electrical operations.

NH/NT 855 Engines

Similarly, in the NH/NT 855 engines, the Switch Bracket 3043118 is utilized to mount and secure switches in a manner that ensures they are both accessible and functional. This bracket is designed to fit the specific layout and design of the NH/NT 855 engines, providing a reliable mounting solution that supports the engine’s electrical components.

By ensuring that the switches are securely mounted and correctly positioned, the Switch Bracket 3043118 contributes to the overall reliability and performance of both the N14 MECHANICAL and NH/NT 855 engines. This part is a testament to Cummins’ commitment to providing high-quality, reliable components that enhance the functionality and longevity of their engines.

Role of Part 3043118 Switch Bracket in Engine Systems

The part 3043118 Switch Bracket is an integral component in various engine systems, particularly those involving brake mechanisms and control systems. It serves as a mounting point and support structure for switches that are essential for the operation of the brake systems.

In the context of the Brake Engine and Cable system, the Switch Bracket securely holds the switches that activate the brake functions. This ensures that the electrical signals are reliably transmitted to the brake actuators, allowing for precise and responsive braking.

For the Cab Controls, the Switch Bracket is used to mount switches that are part of the control interface. These switches are operated by the driver to engage or modulate the brake systems, providing a direct link between the driver’s actions and the brake performance.

In the C Brake (Top Level) Kit, C Brake Kit, and C-Brake (444) Kit, the Switch Bracket plays a similar role. It ensures that the switches are correctly positioned and supported, which is vital for the consistent operation of these brake kits.

The Cable Control Brake and Cable Control Kit also benefit from the Switch Bracket. It provides a stable platform for the switches that control the cable-operated brake systems, ensuring that the cables are actuated smoothly and effectively.

In the Cummins Engine Brake Kit and Engine and Cable Brake systems, the Switch Bracket is essential for mounting the switches that interface with the engine’s electronic control unit (ECU). This allows for the integration of engine braking functions with the overall brake system, enhancing the vehicle’s stopping power and control.

Overall, the part 3043118 Switch Bracket is a fundamental component in ensuring that the switches within various brake and engine systems are securely mounted and operational, contributing to the reliability and performance of the braking mechanisms.

Conclusion

The Cummins 3043118 Switch Bracket is a critical component in the electrical systems of commercial trucks, providing a stable and organized platform for mounting switches. Its robust construction, compatibility with various truck models, and ease of installation make it a valuable asset for fleet management. Regular maintenance and adherence to safety guidelines are essential for ensuring the longevity and reliability of this part.

-

Happian-Smith, Julian. An Introduction to Modern Vehicle Design. Butterworth-Heinemann, 2002.

↩ -

Norman, Andrew. Diesel Technology Fundamentals Service Repair Eighth Edition. The Goodheart-Willcox Company Inc, 2016.

↩ -

Fehan, Douglas R. Design of Racing and High-Performance Engines 2004-2013. SAE International, 2013.

↩ -

ElSayed, Mohamed PE. Fundamentals of Integrated Vehicle Realization. SAE International, 2017.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.