This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

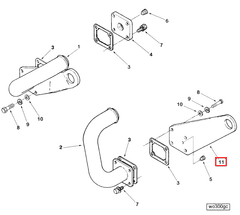

The Cummins 3058533 Lifting Bracket is a component designed for use in commercial truck maintenance and operation. Cummins, a well-established name in the industry, produces a range of parts and systems that contribute to the efficiency and reliability of commercial vehicles. This part plays a role in facilitating the safe and effective maintenance of trucks.

Basic Concepts of Lifting Brackets

A lifting bracket is a device used to secure and lift heavy components during vehicle maintenance. It operates by providing a stable attachment point for lifting equipment, ensuring that the component being moved is held securely. In the context of a commercial truck, lifting brackets are integral to the maintenance process, allowing for the safe removal and replacement of parts such as engines, transmissions, and other heavy assemblies.

Purpose of the 3058533 Lifting Bracket

This Cummins part is specifically designed to aid in the lifting and securing of components during repairs or inspections of commercial trucks. It plays a role in ensuring that the lifting process is conducted safely and efficiently, reducing the risk of damage to both the vehicle and the personnel involved. By providing a secure attachment point, the bracket facilitates the precise and controlled movement of heavy components, which is crucial for complex maintenance tasks.

Key Features

The 3058533 Lifting Bracket boasts several features that enhance its functionality and durability. It is constructed from high-strength materials, ensuring it can withstand the rigors of heavy-duty use. The design incorporates robust attachment points and a sturdy frame, which contribute to its reliability. Additionally, the bracket may include unique attributes such as corrosion-resistant coatings or ergonomic design elements that improve its performance and ease of use.

Benefits

Utilizing the 3058533 Lifting Bracket offers several advantages. It enhances safety during lifting operations by providing a secure and stable attachment point. Its durable construction ensures longevity, reducing the need for frequent replacements. The bracket’s design also contributes to ease of use, allowing for quick and efficient attachment and detachment during maintenance tasks. These benefits collectively contribute to more efficient and safer truck maintenance operations.

Installation Process

Installing the 3058533 Lifting Bracket requires careful attention to detail and adherence to safety protocols. Preparatory steps include ensuring the truck is securely supported and the work area is clear of obstacles. The necessary tools, such as wrenches and alignment tools, should be gathered beforehand. During installation, it is important to follow the manufacturer’s instructions precisely, ensuring that all bolts and fasteners are tightened to the specified torque settings. Safety precautions, such as wearing appropriate personal protective equipment, should be observed throughout the process.

Troubleshooting and Maintenance

Common issues with the 3058533 Lifting Bracket may include wear and tear on attachment points or corrosion. Troubleshooting steps involve inspecting the bracket for signs of damage or deterioration and addressing any issues promptly. Regular maintenance, such as cleaning and applying protective coatings, can help ensure the longevity and optimal performance of the bracket. It is also important to conduct periodic inspections to identify and rectify any potential problems before they lead to more significant issues.

Safety Considerations

When using the 3058533 Lifting Bracket, it is vital to adhere to safety guidelines and best practices. This includes conducting regular inspections of the bracket to ensure it is in good condition and free from damage. Safety protocols should be followed during installation and use, such as securing the truck properly and using appropriate lifting equipment. Additionally, personnel should be trained in the correct use of the bracket to minimize the risk of accidents and ensure a safe working environment.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and related technologies. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-quality components. The company’s commitment to innovation and customer satisfaction has made it a trusted name for truck components, including the 3058533 Lifting Bracket.

Cummins Lifting Bracket 3058533 Compatibility with Cummins Engines

The 3058533 Lifting Bracket is a versatile component designed to fit seamlessly with various Cummins engines. This bracket is essential for the secure and efficient lifting of engine components during maintenance and repair operations. Below is a detailed overview of the compatibility of this lifting bracket with specific Cummins engines.

V903 Engine Series

The 3058533 Lifting Bracket is specifically engineered to fit the V903 engine series. This engine series is known for its robust design and reliability, making it a popular choice in various industrial and commercial applications. The lifting bracket ensures that the engine components are lifted with precision and safety, reducing the risk of damage during maintenance procedures.

Grouping of Compatible Engines

While the V903 engine series is a primary focus, the 3058533 Lifting Bracket is also compatible with other Cummins engines that share similar structural and design characteristics. This compatibility extends to engines within the same family or those that have been designed with similar lifting requirements.

By ensuring that the lifting bracket fits a range of engines, Cummins provides technicians and maintenance personnel with a reliable tool that can be used across multiple engine models, enhancing efficiency and reducing the need for multiple specialized parts.

Role of Part 3058533 Lifting Bracket in Engine Systems

In the orchestration of engine systems, the 3058533 Lifting Bracket assumes a significant role by facilitating the secure attachment and alignment of various components. This bracket is instrumental in ensuring that the components are held in the correct position, thereby contributing to the overall efficiency and safety of the engine operation.

Integration with the Connection

The Lifting Bracket is designed to interface with the connection points of the engine, providing a stable foundation for other components. It ensures that the connections are maintained under operational stresses, which is essential for the integrity of the engine’s performance. The bracket’s design allows for easy access during maintenance, which is beneficial for routine checks and repairs.

Synergy with the Water Outlet

When paired with the water outlet, the Lifting Bracket plays a part in maintaining the correct orientation and support for the outlet. This is particularly important in engines where the water outlet is subject to dynamic forces during operation. The bracket helps in reducing the strain on the water outlet, which can prevent leaks and ensure consistent coolant flow, which is vital for engine temperature regulation.

Overall Component Support

Beyond its specific roles with the connection and water outlet, the Lifting Bracket contributes to the structural integrity of the engine system as a whole. It provides a robust mounting solution that can accommodate various components, ensuring they remain in place and function as intended. This is especially important in high-vibration environments where component stability is paramount.

Conclusion

In summary, the 3058533 Lifting Bracket is a key player in the engine system, offering support and stability to critical components, and thereby enhancing the engine’s reliability and performance. Its compatibility with various Cummins engines, robust design, and ease of use make it an invaluable tool for maintenance and repair operations.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.