This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3073121 Control Bracket is a component designed for use in heavy-duty truck operations. It serves a specific function within the truck’s system, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and significance can help in maintaining and optimizing the performance of heavy-duty trucks.

Purpose and Function

The Cummins 3073121 Control Bracket plays a role in the operation of a truck by providing a secure mounting point for various control systems. It integrates with other components to ensure that control mechanisms are properly positioned and supported. This bracket is part of a larger system that includes sensors, actuators, and other control devices, all working together to manage the truck’s functions 1.

Design and Construction

The Cummins 3073121 Control Bracket is manufactured using high-quality materials that ensure durability and reliability. The production process involves precision engineering to meet the stringent requirements of heavy-duty applications. The materials used are resistant to corrosion and wear, which helps in maintaining the bracket’s integrity over time 2.

Key Features

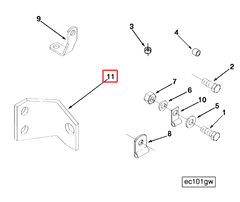

The primary features of the Cummins 3073121 Control Bracket include its robust mounting points, which provide a stable base for control systems. It also features secure attachment mechanisms that ensure the bracket remains firmly in place under various operating conditions. Unique design elements may include reinforced sections to handle higher stress areas and ergonomic considerations for easier installation and maintenance 3.

Benefits

The Cummins 3073121 Control Bracket offers several advantages. It contributes to improved stability of the control systems it supports, which can enhance the overall performance of the truck. Additionally, its design allows for ease of installation, reducing downtime during maintenance procedures. The durability of the bracket ensures long-term reliability, which is crucial for heavy-duty truck operations 4.

Installation Process

Installing the Cummins 3073121 Control Bracket involves several steps to ensure proper integration with the truck’s systems. The process begins with preparing the mounting area, followed by aligning the bracket with the designated points. Tools such as torque wrenches may be required to secure the bracket in place. It is important to follow recommended procedures to avoid damage to the bracket or surrounding components.

Maintenance and Care

To ensure the longevity and optimal performance of the Cummins 3073121 Control Bracket, regular maintenance is recommended. This includes periodic inspections to check for signs of wear or damage. Cleaning the bracket and its mounting points can prevent the buildup of debris that might affect its function. Following these guidelines can help in maintaining the bracket’s condition over time.

Troubleshooting Common Issues

Common issues with the Cummins 3073121 Control Bracket may include loose connections or damage to the mounting points. Diagnostic techniques such as visual inspections and functional tests can help identify problems. Suggested solutions may involve tightening connections or replacing damaged parts. Addressing these issues promptly can help maintain the bracket’s effectiveness.

Cummins Overview

Cummins Inc. is a well-established company in the automotive industry, known for its range of engines and components. With a history of innovation and quality, Cummins has built a reputation for producing reliable and high-performance parts. The company’s product range includes engines, filtration systems, and aftermarket parts, all designed to meet the demands of various applications.

Conclusion

The Cummins 3073121 Control Bracket is a vital component in heavy-duty truck operations, contributing to the stability and efficiency of control systems. Its robust design, ease of installation, and long-term reliability make it an essential part of the truck’s system. Regular maintenance and prompt troubleshooting of common issues can ensure the continued performance and longevity of this Cummins part.

-

Taghavifar, H., & Mardani, A. (2017). Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer.

↩ -

Bonnick, A. (2004). A Practical Approach to Motor Vehicle Engineering and Maintenance. Elsevier.

↩ -

Rajamani, R. (2005). Vehicle Dynamics and Control. Springer.

↩ -

Minaker, B. P. (2019). Fundamentals of Vehicle Dynamics and Modelling. John Wiley & Sons.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.