This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

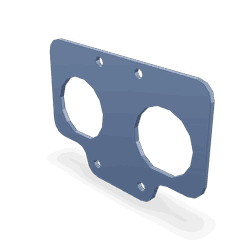

The Wiring Retainer Bracket, identified by part number 3092051, is a component manufactured by Cummins, a well-established name in the commercial vehicle industry. This bracket is integral to the electrical systems of heavy-duty trucks, ensuring the secure and organized placement of wiring harnesses. Its application in commercial vehicles underscores the importance of reliable and efficient electrical management in maintaining vehicle performance and safety 1.

Purpose and Function

The Wiring Retainer Bracket serves a pivotal role in the electrical system of a truck by securing and organizing wiring harnesses. This function is vital for preventing damage to the wires, which can occur due to vibrations or movement during operation. By maintaining the integrity and position of the wiring, the bracket contributes to the efficient operation of the truck’s electrical system, reducing the likelihood of electrical faults that could arise from unsecured or damaged wires 2.

Key Features

The design and material characteristics of the Wiring Retainer Bracket are tailored to withstand the harsh operating environments typical of heavy-duty trucks. Constructed from durable materials, the bracket is resistant to corrosion and physical wear, ensuring longevity and reliability. Its design allows for easy installation and adjustment, accommodating various wiring configurations and ensuring a snug fit that secures the harnesses effectively 3.

Benefits

Utilizing the Wiring Retainer Bracket offers several advantages. It enhances wire management by keeping harnesses organized and protected, which in turn reduces the risk of electrical faults. This organized approach to wiring not only improves the reliability of the truck’s electrical system but also enhances safety by minimizing the potential for electrical issues that could compromise vehicle operation 4.

Installation and Compatibility

Proper installation of the Wiring Retainer Bracket is crucial for its effective function. Installation procedures should follow manufacturer guidelines to ensure the bracket is securely fastened and correctly positioned. While specific compatibility details are provided separately, it is important to note that this bracket is designed for use in a variety of truck models and engine types, ensuring broad applicability across the commercial vehicle sector.

Maintenance and Troubleshooting

Regular inspection and maintenance of the Wiring Retainer Bracket are recommended to ensure its continued effectiveness. This includes checking for signs of wear or damage and ensuring that the wiring harnesses remain securely fastened. Common issues may include loosening of the bracket or damage to the wiring, which can often be addressed through re-securing the bracket or repairing the wiring as necessary.

Safety Considerations

A well-maintained Wiring Retainer Bracket plays a role in the overall safety of the truck by ensuring the electrical system operates reliably. Adhering to manufacturer guidelines for installation and maintenance is important for optimal performance and safety, helping to prevent electrical faults that could lead to more serious issues.

Cummins: Manufacturer Overview

Cummins Inc. is a leading manufacturer in the commercial vehicle industry, known for its wide range of products and commitment to quality and innovation. With a history of providing reliable and high-performance components, Cummins has established a reputation for excellence. The company’s focus on advancing technology and meeting the needs of its customers underscores its position as a trusted provider in the automotive components market.

Wiring Retainer Bracket 3092051 Compatibility with Cummins Engines

The Wiring Retainer Bracket part number 3092051, manufactured by Cummins, is designed to be compatible with a range of Cummins engines. This part is crucial for securing and organizing the wiring within the engine compartment, ensuring that electrical connections remain stable and protected.

QST30 Series

The QST30 series includes engines such as the QST30 CM2350 T101 and QST30 CM552. The Wiring Retainer Bracket 3092051 fits seamlessly into these engines, providing a reliable method to manage the wiring harness. This bracket helps maintain the integrity of the electrical system by preventing wires from becoming loose or damaged due to engine vibrations or movement.

CM2350 T101

For the QST30 CM2350 T101 engine, the Wiring Retainer Bracket 3092051 is specifically engineered to align with the engine’s design. It ensures that the wiring is neatly routed and secured, which is essential for the engine’s optimal performance and longevity. The bracket’s placement is critical to avoid interference with other engine components, ensuring smooth operation.

CM552

Similarly, the QST30 CM552 engine benefits from the use of the Wiring Retainer Bracket 3092051. This part is designed to fit the unique layout of the CM552 engine, providing a secure mounting point for the wiring harness. By doing so, it helps in maintaining the electrical system’s efficiency and reliability, reducing the risk of electrical faults that could lead to engine downtime.

In both engines, the bracket’s design ensures that it can be easily installed and removed, facilitating maintenance and repairs. Its robust construction guarantees that it can withstand the operational stresses of the engine environment, providing long-term durability and performance.

Role of Part 3092051 Wiring Retainer Bracket in Engine Systems

The part 3092051 Wiring Retainer Bracket is instrumental in maintaining the integrity and organization of the wiring systems within engine assemblies. This component is specifically designed to secure and route the Electronic Control Module (ECM) wiring harness, ensuring that it remains protected from potential damage caused by engine vibrations, heat, and other environmental factors.

When installed, the Wiring Retainer Bracket clamps down on the ECM wiring harness, holding it in place against the engine block or other sturdy components. This not only prevents the wires from chafing against moving parts but also helps in dissipating heat away from sensitive electronic components.

Moreover, the bracket plays a significant role in the Engine Control Module (ECM) system by ensuring that the wiring harness is correctly positioned. This is essential for maintaining the efficiency of the ECM, which relies on accurate and consistent data from various sensors distributed throughout the engine. Proper placement and securement of the wiring harness by the retainer bracket facilitate optimal signal transmission, thereby enhancing the overall performance and reliability of the engine control system.

Conclusion

In summary, the 3092051 Wiring Retainer Bracket is a key component in the engine’s electrical system, providing necessary support and protection to the ECM wiring harness, and contributing to the seamless operation of the Engine Control Module.

-

Huzij, R., Spano, A., & Bennett, S. (2019). Modern Diesel Technology: Heavy Equipment Systems. Cengage Learning.

↩ -

Mananathan, R. (2022). Automobile Wheel Alignment and Wheel Balancing. SAE International.

↩ -

Kasab, J., & Strzelec, A. (2020). Automotive Emissions Regulations and Exhaust Aftertreatment Systems. SAE International.

↩ -

Fischer, R., Kucukay, F., Jurgens, G., Najork, R., & Pollak, B. (2015). The Automotive Transmission Book Powertrain. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.