This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

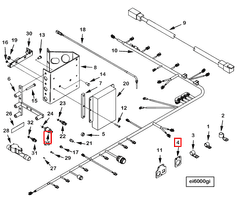

The Cummins 3092052 Wiring Retainer Bracket is a component designed to secure and organize wiring harnesses within heavy-duty trucks. Its role is significant in maintaining the integrity and performance of the truck’s electrical system. By providing a structured environment for the wiring, it helps ensure that the electrical connections remain secure and protected from potential damage 3.

Purpose and Function

The Wiring Retainer Bracket serves to hold wiring harnesses in place, preventing them from moving or becoming dislodged during operation. This bracket contributes to the overall electrical system integrity by reducing the risk of wire chafing, abrasion, and disconnection. It also aids in organizing the wiring, which can simplify troubleshooting and maintenance tasks. The secure placement of wires ensures consistent electrical performance and reduces the likelihood of faults that could arise from unsecured wiring 1.

Key Features

The design of the Cummins 3092052 incorporates durable materials that can withstand the harsh conditions typical of heavy-duty truck environments. It is engineered to be robust, providing long-lasting support for the wiring harnesses. The bracket’s construction includes features that enhance its effectiveness, such as secure mounting points and a design that accommodates various wiring configurations. These attributes contribute to its reliability in demanding applications 3.

Benefits

Utilizing the Cummins 3092052 offers several advantages. It improves wire management by keeping the harnesses organized and protected. This organization reduces the risk of electrical faults that can occur when wires are left unsecured. Additionally, the bracket enhances the safety and reliability of the truck’s electrical system by ensuring that all connections remain intact and functioning correctly. This can lead to improved overall performance and longevity of the electrical components 1.

Installation and Compatibility

Proper installation of the Wiring Retainer Bracket is crucial for its effectiveness. It should be mounted according to the manufacturer’s guidelines to ensure it securely holds the wiring harnesses in place. Compatibility with specific truck models and engine types is important to ensure correct application. Following the provided instructions during installation will help maintain the integrity of the electrical system 2.

Maintenance and Troubleshooting

Regular inspection of the Wiring Retainer Bracket is recommended to ensure its ongoing functionality. During maintenance checks, look for signs of wear, damage, or loose connections. Common issues may include bracket misalignment or wire abrasion. Addressing these issues promptly can prevent more significant problems. Troubleshooting steps may involve re-securing the bracket, replacing damaged components, or adjusting the wiring to ensure it fits properly within the bracket 3.

Safety Considerations

When working with the Wiring Retainer Bracket and the truck’s electrical system, it is important to follow safety practices to avoid electrical hazards. Ensure the truck’s power is off before beginning any work on the electrical components. Use appropriate personal protective equipment (PPE) and follow all safety guidelines provided by the manufacturer. Taking these precautions will help ensure personal safety and prevent accidents 1.

Cummins Overview

Cummins Inc. is a leading manufacturer of diesel engines and related technologies, with a history of innovation and quality in the automotive industry. The company is known for developing and producing a wide range of components, including the Wiring Retainer Bracket, that are designed to meet the demanding requirements of heavy-duty applications. Cummins’ commitment to quality and performance is evident in the design and functionality of their products 3.

Compatibility with Cummins Engines

The Wiring Retainer Bracket part number 3092052, manufactured by Cummins, is designed to fit seamlessly with a variety of Cummins engines. This bracket is a component for securing and organizing the engine’s wiring, ensuring that electrical connections remain stable and protected during operation.

QST30 CM552 Engines

For the QST30 CM552 engines, the Wiring Retainer Bracket 3092052 is specifically engineered to fit the engine’s architecture. This bracket is crucial for maintaining the integrity of the electrical system by preventing wires from becoming dislodged or damaged due to engine vibrations or movement. Its precise fit ensures that the bracket can be easily installed and removed, facilitating maintenance and repairs 2.

Other Cummins Engines

The Wiring Retainer Bracket 3092052 is also compatible with other Cummins engines, providing a reliable solution for securing wiring in various engine configurations. Cummins has designed this bracket to be versatile, allowing it to fit a range of engine models while maintaining the same high standards of quality and performance. This versatility makes it a valuable component for technicians and mechanics working with multiple engine types 3.

Role in Engine Systems

The 3092052 Wiring Retainer Bracket is a component in the organization and protection of wiring within engine systems. It ensures that wires are securely held in place, reducing the risk of chafing, abrasion, and potential short circuits.

In the context of a Monitor, the Wiring Retainer Bracket plays a significant role in maintaining the integrity of the wiring that connects various sensors and feedback mechanisms. By securing these wires, it ensures that the monitor receives accurate and consistent data from the engine components, allowing for precise monitoring and diagnostics 1.

For an Electronic Engine, the Wiring Retainer Bracket is equally important. It organizes the complex network of wires that power the engine’s electronic control unit (ECU), fuel injectors, ignition system, and other electronic components. This organization is vital for the efficient operation of the engine, as it prevents wires from interfering with moving parts or becoming damaged due to heat or vibration 2.

Additionally, the Wiring Retainer Bracket helps in managing the thermal environment around the wires. By keeping wires away from high-temperature areas and ensuring proper airflow, it contributes to the overall reliability and longevity of the engine’s electrical system.

Conclusion

The Cummins 3092052 Wiring Retainer Bracket is a key component in maintaining the structural and functional integrity of the wiring within engine systems, supporting both monitoring and electronic engine operations. Its robust design, ease of installation, and compatibility with various Cummins engines make it an essential part for ensuring the reliability and performance of heavy-duty truck electrical systems 3.

-

Tyres Suspension and Handling Second Edition, John C Dixon, SAE International, 1996

↩ ↩ ↩ ↩ -

X15 CM2350 X125M, Bulletin Number 5504346, Fault Code Troubleshooting Manual

↩ ↩ ↩ -

Diesel Technology Fundamentals Service Repair Eighth Edition, Andrew Norman, The Goodheart-Willcox Company Inc, 2016

↩ ↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.