This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

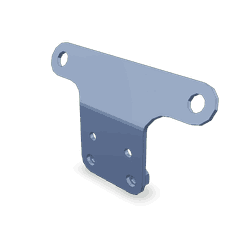

The Cummins 3092245 Wiring Retainer Bracket is a component designed to secure and organize wiring harnesses in heavy-duty trucks. Its role is significant in maintaining the integrity and efficiency of the vehicle’s electrical system. By ensuring that wires are properly managed, the bracket contributes to the overall reliability and performance of the truck 1.

Purpose and Function

The Wiring Retainer Bracket serves to secure and organize the wiring harnesses within the truck’s electrical system. It plays a role in preventing wires from coming into contact with moving parts or sharp edges, which could lead to damage. Additionally, it helps maintain reliable electrical connections by keeping wires in their designated paths, reducing the likelihood of shorts or disconnections 2.

Key Features

The Cummins 3092245 Wiring Retainer Bracket is constructed from durable materials, ensuring it can withstand the harsh conditions often encountered in heavy-duty truck operations. Its design includes features that facilitate easy mounting and adjustment, allowing for versatile installation across different truck models. The bracket is engineered to accommodate various wiring configurations, enhancing its functionality and adaptability 3.

Benefits

The use of the Wiring Retainer Bracket offers several advantages. It improves wire management by keeping harnesses organized and protected, which can lead to a reduction in electrical faults. The bracket’s durable construction contributes to its longevity, ensuring it remains effective over time. Furthermore, by maintaining reliable electrical connections, it plays a part in enhancing overall vehicle safety and performance 4.

Installation and Compatibility

Proper installation of the Wiring Retainer Bracket is crucial for its effectiveness. Guidelines for installation should be followed to ensure it is securely mounted and correctly positioned. The bracket is designed to be compatible with a range of truck models and engine types, making it a versatile component for diverse fleet settings. Ensuring compatibility is important for the correct application and optimal performance of the bracket.

Maintenance and Troubleshooting

Routine maintenance of the Wiring Retainer Bracket is recommended to ensure its continued effectiveness. This may include checking for signs of wear or damage and ensuring that wires remain securely fastened. Troubleshooting common issues related to wiring harness management and electrical connections can often be addressed by verifying the bracket’s installation and condition, and making adjustments as necessary.

Safety Considerations

When installing or maintaining the Wiring Retainer Bracket, it is important to observe safety protocols and precautions. This includes ensuring that the electrical system is properly managed to avoid risks associated with exposed wires or faulty connections. The importance of proper electrical system management for overall vehicle safety cannot be overstated, as it plays a role in preventing accidents and ensuring the truck operates efficiently.

Cummins Overview

Cummins Inc. is a company with a long history of expertise in diesel engine manufacturing. It is committed to providing reliable components for the commercial trucking industry. The company’s focus on quality and performance is evident in its range of products, including the Cummins 3092245 Wiring Retainer Bracket, which is designed to meet the demanding requirements of heavy-duty truck operations.

Cummins Wiring Retainer Bracket 3092245 Compatibility

The Cummins Wiring Retainer Bracket part number 3092245 is designed to fit seamlessly with a variety of Cummins engines, ensuring secure and organized wiring management. This bracket is crucial for maintaining the integrity of the electrical system by holding wiring in place, preventing tangling, and protecting against wear and tear.

QST30 CM552 Engines

For the QST30 CM552 engines, the Wiring Retainer Bracket 3092245 is engineered to fit precisely, providing a reliable solution for managing the engine’s wiring. This bracket is essential for maintaining the efficiency and safety of the engine’s electrical system, ensuring that all wiring is properly secured and protected.

Grouping of Compatible Engines

The Wiring Retainer Bracket 3092245 is not limited to the QST30 CM552 engines but is also compatible with a range of other Cummins engines. This part is designed to fit various engine models, making it a versatile solution for multiple applications. The bracket’s universal design ensures that it can be used across different engine types, providing a consistent and reliable fit.

By using the Wiring Retainer Bracket 3092245, engine operators can ensure that their electrical systems remain organized and protected, contributing to the overall performance and longevity of their engines.

Role of Part 3092245 Wiring Retainer Bracket in Engine Systems

The 3092245 Wiring Retainer Bracket is an essential component in maintaining the integrity and organization of wiring systems within engine setups. It is specifically designed to secure and manage wiring harnesses and cables, ensuring they remain in place and are protected from potential damage during engine operation.

Integration with Aftercooler (Left) Brackets

When installed alongside the aftercooler (left) brackets, the 3092245 Wiring Retainer Bracket helps in routing and securing wiring that runs adjacent to the aftercooler. This ensures that the wiring does not interfere with the aftercooler’s operation or become damaged due to vibrations or heat. The retainer bracket provides a stable mounting point, reducing the risk of wire chafing or disconnection, which could lead to performance issues or electrical faults.

Coordination with Engine Control Module (ECM)

The Engine Control Module (ECM) relies on a network of wires to communicate with various sensors and actuators throughout the engine system. The 3092245 Wiring Retainer Bracket plays a significant role in organizing these wires, preventing them from becoming tangled or stressed. By securing the wiring near the ECM, the bracket helps maintain a clean and efficient pathway for signals, ensuring reliable data transmission and overall system performance.

Support for Engine Control Module Mounting

In scenarios where the ECM is mounted in proximity to the wiring retainer bracket, the 3092245 component aids in maintaining a tidy and secure wiring environment. This is particularly important in high-vibration environments where unsecured wiring could lead to intermittent connections or complete failures. The bracket ensures that the wires remain taut and organized, supporting the ECM’s function by providing a stable and protected wiring layout.

Conclusion

Overall, the 3092245 Wiring Retainer Bracket is a key element in the engine’s electrical system, enhancing both the durability and reliability of the wiring infrastructure. Its role in securing and organizing wiring harnesses is critical for maintaining the efficiency and safety of heavy-duty truck operations.

-

Atkins, R. D. (2009). An Introduction to Engine Testing and Development. SAE International.

↩ -

Huang, M. (2002). Vehicle Crash Dynamics. CRC Press.

↩ -

Hilgers, M. (2023). Fuel Consumption and Consumption Optimization, Second Edition. Springer Nature.

↩ -

Naunheimer, H., Bertsche, B., Ryborz, J., & Novak, W. (2011). Automotive Transmissions Fundamentals Selection Design and Application. Springer Vieweg.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.