This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

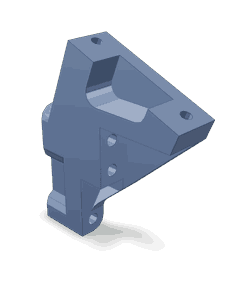

The Cummins Pump Bracket 3093263 is a component designed for use in heavy-duty trucks, specifically engineered to support and secure various pump types within a truck’s engine system. This part ensures the stability and efficiency of pump operations, which are vital for the engine’s performance and reliability 1.

Basic Concepts of Pump Brackets

A pump bracket is a structural component that secures and supports pumps within an engine system. Its primary function is to provide a stable mounting point for the pump, ensuring it remains securely in place during operation. This stability minimizes movement and vibration, contributing to the overall stability and efficiency of the pump’s operation within the engine system 2.

Purpose of Pump Bracket 3093263 in Truck Operation

The Pump Bracket 3093263 is specifically designed to support and secure pumps in heavy-duty truck engines manufactured by Cummins. It interacts with other engine components to ensure the pump operates within the optimal parameters for performance and reliability. By providing a stable mounting solution, the bracket contributes to the truck’s overall performance, ensuring the pump functions efficiently under various operating conditions 3.

Key Features of Pump Bracket 3093263

The Pump Bracket 3093263 is characterized by its robust design and material selection, which are tailored to meet the demanding requirements of heavy-duty truck engines. It is constructed from high-strength materials to ensure durability and resistance to the stresses encountered in truck engine environments. The design of the bracket includes features that enhance its compatibility with Cummins engines, ensuring a secure fit and optimal performance 4.

Benefits of Using Pump Bracket 3093263

The use of the Pump Bracket 3093263 offers several advantages, including improved engine stability, reduced vibration, and enhanced pump efficiency. By securely mounting the pump, the bracket helps to minimize movement and vibration, which can contribute to improved engine performance and reliability. Additionally, the stable mounting provided by the bracket can lead to more efficient pump operation, potentially contributing to better fuel economy and reduced emissions 5.

Installation and Compatibility

Proper installation of the Pump Bracket 3093263 is important to ensure its effectiveness and compatibility with Cummins engine models. Installation guidelines should be followed to ensure the bracket is securely mounted and aligned correctly with the pump and engine components. The bracket is designed to be compatible with a range of Cummins engine models, ensuring it can be used across various heavy-duty truck applications 6.

Troubleshooting and Maintenance

Common issues associated with pump brackets can include misalignment, wear, or damage, which may affect the pump’s operation. Regular inspection and maintenance of the Pump Bracket 3093263 are recommended to ensure its longevity and optimal performance. Maintenance procedures may include checking for signs of wear or damage, ensuring the bracket remains securely mounted, and addressing any issues promptly to prevent further complications 7.

Cummins: Manufacturer Overview

Cummins Inc. is a leading manufacturer in the heavy-duty truck industry, known for its wide range of products and commitment to quality and innovation. The company has a long history of providing reliable and high-performance engine solutions for various applications. Cummins’ reputation is built on its dedication to customer satisfaction, ensuring that its products, including the Pump Bracket 3093263, meet the high standards expected in the heavy-duty truck industry 8.

Compatibility with Cummins Engines

The Pump Bracket 3093263 is designed to fit seamlessly with a variety of Cummins engines, ensuring a secure and reliable connection for the pump assembly. This bracket is integral to maintaining the structural integrity and operational efficiency of the engine.

QST30 CM552 Engines

The 3093263 Pump Bracket is specifically engineered to integrate with the QST30 CM552 engines. This bracket plays a role in aligning and securing the pump, facilitating smooth operation and reducing wear and tear on the engine components. Its precision-engineered design ensures compatibility with the unique specifications of the QST30 CM552 engines, providing a robust solution for maintaining engine performance 9.

Other Cummins Engines

In addition to the QST30 CM552 engines, the 3093263 Pump Bracket is also compatible with a range of other Cummins engines. This versatility allows for a broad application across various engine models, making it a valuable component for maintenance and repair purposes. The bracket’s design accommodates the specific mounting points and alignment requirements of these engines, ensuring a secure fit and optimal performance 10.

Role of Pump Bracket 3093263 in Engine Systems

The Pump Bracket 3093263 serves as a mounting point, securing the Fuel Injection Pump (FIP) to the engine block or other structural components. By providing a stable and precise mounting location, the bracket ensures that the FIP remains correctly aligned with the camshaft and other related components. This alignment is necessary for the accurate timing of fuel injection, which directly influences engine performance, fuel efficiency, and emissions.

Additionally, the Pump Bracket helps in managing the stresses and vibrations that the FIP experiences during engine operation. It distributes these forces across the engine structure, preventing undue strain on the pump itself. This not only enhances the durability of the FIP but also contributes to the overall reliability of the engine system 11.

Conclusion

The Pump Bracket 3093263 plays a significant role in maintaining the structural integrity and operational precision of the Fuel Injection Pump within engine systems. Its robust design, compatibility with various Cummins engines, and the benefits it offers in terms of engine stability and efficiency make it a critical component in the operation of heavy-duty trucks.

-

Road and Off-Road Vehicle Dynamics, Moustafa ElGindy and Zeinab ElSayegh, Springer Nature, 2023.

↩ -

Heavy Duty Truck Systems Fifth Edition, Sean Bennett, Ian Andrew Norman, Delmar Cengage Learning, 2011.

↩ -

The History and Impact of Diesel Engines and Gas Turbines, Vaclav Smil, The MIT Press, 2010.

↩ -

Operation and Maintenance Manual, QSF3.8 CM2880 F112, Bulletin Number 4383826.

↩ -

Road and Off-Road Vehicle Dynamics, Moustafa ElGindy and Zeinab ElSayegh, Springer Nature, 2023.

↩ -

Heavy Duty Truck Systems Fifth Edition, Sean Bennett, Ian Andrew Norman, Delmar Cengage Learning, 2011.

↩ -

The History and Impact of Diesel Engines and Gas Turbines, Vaclav Smil, The MIT Press, 2010.

↩ -

Operation and Maintenance Manual, QSF3.8 CM2880 F112, Bulletin Number 4383826.

↩ -

Road and Off-Road Vehicle Dynamics, Moustafa ElGindy and Zeinab ElSayegh, Springer Nature, 2023.

↩ -

Heavy Duty Truck Systems Fifth Edition, Sean Bennett, Ian Andrew Norman, Delmar Cengage Learning, 2011.

↩ -

The History and Impact of Diesel Engines and Gas Turbines, Vaclav Smil, The MIT Press, 2010.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.