This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

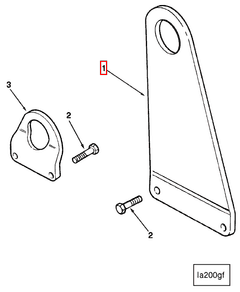

The Cummins 3251231 Lifting Bracket is a component designed to facilitate the safe and efficient lifting of commercial trucks during maintenance and repair activities. Its role is significant in the context of commercial truck maintenance and operation, as it ensures that lifting processes are conducted with precision and safety, thereby contributing to the overall efficiency and safety of maintenance operations 1.

Purpose and Functionality

This Cummins part plays a role in the operation of a truck by providing a secure point of attachment for lifting equipment. The bracket is engineered to distribute the weight of the truck evenly during lifting, which is crucial for preventing damage to the vehicle and ensuring the safety of personnel involved in the lifting process 2. By facilitating safe and efficient lifting, it allows for thorough inspections and repairs that might otherwise be difficult or dangerous to perform.

Key Features

The primary features of the 3251231 Lifting Bracket include its robust design, which is crafted from high-strength materials to withstand the stresses of lifting heavy loads. The bracket is designed to be compatible with a variety of lifting equipment, ensuring versatility in its application. Its construction includes reinforced points for attachment, which enhance its durability and reliability under load 3.

Benefits

Using the 3251231 Lifting Bracket offers several advantages. It contributes to improved safety by providing a secure attachment point for lifting equipment, reducing the risk of accidents during maintenance operations. Additionally, it enhances efficiency by allowing for quicker and more straightforward lifting processes. This can lead to potential cost savings in maintenance operations by minimizing the time and resources required for lifting tasks.

Installation Process

The proper installation of the 3251231 Lifting Bracket involves several steps. It is important to use the appropriate tools and follow safety precautions to ensure a secure and effective installation. The process includes locating the correct position on the truck frame, aligning the bracket, and securing it in place with the provided fasteners. Detailed instructions and safety guidelines should be followed to prevent damage to the bracket or the truck.

Maintenance and Care

To ensure the longevity and reliable performance of the 3251231 Lifting Bracket, regular maintenance and care are recommended. This includes cleaning the bracket to remove any debris or corrosion, inspecting it for signs of wear or damage, and performing any necessary repairs or replacements. Adhering to a maintenance schedule helps to identify potential issues before they lead to failure, ensuring the bracket remains in optimal condition.

Troubleshooting Common Issues

Common problems that may arise with the 3251231 Lifting Bracket include corrosion, wear on attachment points, and structural damage. Addressing these issues promptly is important to maintain the bracket’s functionality. Solutions may involve cleaning and treating corrosion, replacing worn fasteners, or repairing structural damage. Regular inspections can help identify these issues early, allowing for timely intervention.

Compatibility and Usage

The 3251231 Lifting Bracket is designed for use with specific types of trucks and models. Its application is versatile, suitable for a range of maintenance scenarios where secure lifting is required. Understanding the compatibility of the bracket with different truck models ensures its effective use in various maintenance operations.

Safety Considerations

When using the 3251231 Lifting Bracket, adhering to safety protocols is paramount to prevent accidents and ensure the well-being of personnel. This includes conducting a pre-lift inspection of the bracket and lifting equipment, ensuring all fasteners are secure, and following load limits and operational guidelines. Safety training for personnel involved in lifting operations is also recommended to promote a safe working environment.

Cummins Corporation

Cummins Corporation is a renowned provider of automotive components, with a history of innovation and quality in the commercial truck industry. The company’s product range includes a variety of parts and systems designed to enhance the performance, efficiency, and safety of commercial vehicles. Cummins’ reputation for reliability and excellence makes it a trusted choice for automotive components, including the 3251231 Lifting Bracket.

Cummins Lifting Bracket 3251231 Compatibility with Engine Models

The Cummins Lifting Bracket part number 3251231 is a critical component designed to facilitate the lifting and handling of various engine models. This part is engineered to ensure secure and efficient lifting operations, providing a reliable solution for maintenance and repair tasks.

L10 Series Engines

The Cummins Lifting Bracket 3251231 is compatible with both the L10 GAS and L10 MECHANICAL engines. These engines, part of the L10 series, are known for their robust design and reliability. The bracket is specifically designed to fit the unique mounting points and structural requirements of these engines, ensuring a secure fit and ease of use during lifting operations.

M11 Series Engines

Similarly, the Cummins Lifting Bracket 3251231 is also compatible with the M11 CELECT PLUS and M11 MECHANICAL engines. The M11 series engines are recognized for their advanced technology and performance. The bracket’s design accommodates the specific mounting configurations of these engines, providing a seamless integration that enhances the efficiency of lifting and handling procedures.

By ensuring compatibility with these engine models, the Cummins Lifting Bracket 3251231 offers a versatile solution for technicians and maintenance personnel, facilitating safe and effective engine handling across different engine types.

Role of Part 3251231 Lifting Bracket in Engine Systems

In the context of engine systems, the 3251231 Lifting Bracket is integral to the overall lifting arrangement. This component is designed to provide a secure and stable connection point for lifting operations, ensuring that the engine can be safely moved and positioned as required.

When integrated into the lifting arrangement, the 3251231 Lifting Bracket works in conjunction with other lifting components to distribute the load evenly. This helps prevent undue stress on any single point, which could lead to structural failure or damage to the engine. The bracket’s design allows for precise alignment and attachment, making it easier to use lifting equipment such as cranes or hoists.

In practical applications, the Lifting Bracket is often attached to key points on the engine, such as the engine block or frame. This setup ensures that when the lifting operation commences, the engine remains balanced and secure. The bracket’s robust construction is engineered to handle the weight and stress associated with lifting heavy engine components, providing reliability and safety during maintenance, installation, or transportation.

Additionally, the presence of the 3251231 Lifting Bracket in the lifting arrangement simplifies the process of attaching and detaching lifting gear. This efficiency is particularly beneficial in time-sensitive operations, allowing mechanics and engineers to perform tasks with greater speed and confidence.

Overall, the 3251231 Lifting Bracket plays a significant role in enhancing the safety and effectiveness of engine lifting procedures, contributing to a smoother and more reliable workflow in engine maintenance and installation processes.

Conclusion

The Cummins 3251231 Lifting Bracket is a vital component in the maintenance and repair of commercial trucks and engines. Its robust design, compatibility with various engine models, and role in ensuring safe and efficient lifting operations make it an indispensable tool for technicians and maintenance personnel. Regular maintenance, proper installation, and adherence to safety protocols are essential to maximize the benefits of this Cummins part, ensuring reliable and safe lifting operations across different applications.

-

Reif, Konrad Ed. Diesel Engine Management Systems and Components. Springer Vieweg, 2014.

↩ -

Goodnight, Nicholas, and Kirk VanGelder. Automotive Braking Systems CDX Master Automotive Technician Series. Jones Bartlett Learning, 2019.

↩ -

Mollenhauer, Klaus, and Helmut Tschoeke. Handbook of Diesel Engines. Springer, 2010.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.