This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

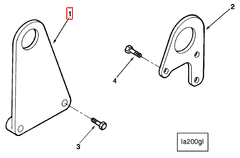

The Cummins 3251557 Lifting Bracket is a specialized component designed for use in commercial trucks. Its purpose is to facilitate the safe and efficient lifting and securing of heavy components during maintenance and repair procedures. This bracket is integral to ensuring that operations are conducted smoothly and safely, highlighting its significance in the maintenance routines of commercial vehicles.

Purpose and Functionality

The 3251557 Lifting Bracket plays a role in the operation of a truck by providing a secure point for lifting equipment to attach to heavy components. This is particularly useful during the removal and installation of major parts such as engines or transmissions. By offering a stable and reliable attachment point, the bracket helps in minimizing the risk of accidents and ensures that the lifting process is conducted with precision and safety 1.

Key Features

The design of the 3251557 Lifting Bracket incorporates several key features that enhance its performance and durability. It is constructed from high-strength materials, ensuring it can withstand the rigors of heavy-duty use. The bracket’s design includes reinforced attachment points and a robust frame, which contribute to its stability and reliability. Additionally, its unique attributes, such as corrosion-resistant coatings, further enhance its longevity in various operating environments 2.

Benefits

Using the 3251557 Lifting Bracket offers several benefits. It improves safety during lifting operations by providing a secure attachment point, reducing the likelihood of accidents. The bracket also enhances stability, ensuring that components are lifted evenly and without unexpected movements. Furthermore, its design allows for ease of use, making it a practical tool for maintenance professionals 3.

Installation Process

Proper installation of the 3251557 Lifting Bracket involves several steps. First, ensure the truck is securely parked on a level surface and the engine is turned off. Use appropriate tools to attach the bracket to the designated points on the truck’s frame. It is important to follow the manufacturer’s instructions closely to ensure a secure fit. Safety precautions, such as wearing protective gear and ensuring the work area is clear of obstacles, should be observed throughout the installation process.

Maintenance and Care

Regular maintenance and care of the 3251557 Lifting Bracket are necessary to ensure its longevity and optimal performance. This includes cleaning the bracket to remove any dirt or debris that may accumulate, inspecting it for signs of wear or damage, and performing any necessary repairs promptly. Adhering to a maintenance schedule will help in identifying potential issues before they become significant problems.

Troubleshooting Common Issues

Common issues with the 3251557 Lifting Bracket may include corrosion, wear on attachment points, or structural damage. To address these problems, first, inspect the bracket thoroughly to identify the specific issue. Corrosion can often be mitigated with a corrosion-resistant coating, while worn attachment points may require reinforcement or replacement. Structural damage should be assessed by a professional to determine the appropriate course of action.

Safety Considerations

When using the 3251557 Lifting Bracket, several safety considerations should be kept in mind. Always adhere to the manufacturer’s guidelines for proper usage, including load limits and recommended lifting techniques. Regular inspections of the bracket for any signs of damage or wear are crucial to ensure it remains safe to use. Additionally, ensuring that all personnel involved in the lifting operation are trained and aware of safety protocols is important for maintaining a safe work environment.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its commitment to quality and innovation. With a rich history of producing reliable and high-performance truck components, Cummins has established a reputation for excellence. The company’s dedication to advancing technology and improving the efficiency and safety of commercial vehicles underscores its position as a trusted provider in the industry.

Cummins Lifting Bracket 3251557 in Engine Applications

The Cummins Lifting Bracket 3251557 is a critical component used in various engine configurations, ensuring secure and efficient lifting operations during maintenance and repair processes. This part is designed to fit seamlessly with several Cummins engines, providing a reliable connection point for lifting equipment.

M11 Mechanical Engine

In the M11 Mechanical engine, the Lifting Bracket 3251557 is strategically positioned to support the engine during lifting procedures. Its robust design ensures that the bracket can withstand the stresses associated with engine handling, providing a stable and secure attachment point. This is particularly important in heavy-duty applications where the engine’s weight and the need for precise lifting are paramount.

Grouping of Engines

The Cummins Lifting Bracket 3251557 is engineered to be compatible with a range of Cummins engines, making it a versatile component in various engine groups. Its design allows for easy installation and removal, facilitating efficient maintenance routines. The bracket’s compatibility extends across different engine models, ensuring that it can be used in multiple applications without the need for modifications.

By integrating the Lifting Bracket 3251557 into the engine’s structure, technicians can perform lifting tasks with confidence, knowing that the bracket is built to handle the demands of the job. This part’s reliability and ease of use make it an essential component in the maintenance toolkit for Cummins engines.

Role of Part 3251557 Lifting Bracket in Engine Systems

The part 3251557 Lifting Bracket is an essential component in the arrangement and maintenance of various engine systems. Its primary function is to facilitate the safe and efficient lifting of heavy engine components, such as the alternator.

When an alternator needs to be accessed for maintenance or replacement, the Lifting Bracket provides a secure point for lifting equipment to attach. This ensures that the alternator can be removed without causing damage to surrounding components or posing a risk to the technician.

In addition to the alternator, the Lifting Bracket can be used in conjunction with other engine components that require lifting. This includes but is not limited to, the starter motor, exhaust manifolds, and certain engine blocks.

The Lifting Bracket is designed to distribute the lifting force evenly, reducing the risk of component deformation or failure during the lifting process. This is particularly important in high-stress areas of the engine where components are already subjected to significant mechanical loads.

Furthermore, the Lifting Bracket plays a role in the overall arrangement of engine components. By providing a stable lifting point, it allows for precise positioning of components during installation or reassembly. This ensures that all components are aligned correctly, which is essential for the proper functioning of the engine.

Conclusion

In summary, the part 3251557 Lifting Bracket is a versatile and reliable component that enhances the safety and efficiency of engine maintenance procedures. Its use in lifting and arranging various engine components underscores its importance in engine systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.