This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

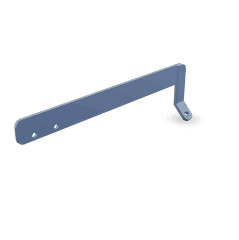

The Cummins 3282318 Shipping Bracket is designed to secure and protect truck components during transportation. This part plays a crucial role in commercial truck operations by ensuring that parts remain fixed and protected during transit, contributing to the efficiency and reliability of truck maintenance and repair processes.

Purpose and Function

The Shipping Bracket serves to secure and protect truck components during transportation. By providing a stable mounting point, it prevents parts from shifting or becoming damaged en route. This function is vital for maintaining the integrity of the components, ensuring they arrive in the condition required for installation and use 1.

Key Features

The primary features of the 3282318 include its robust design, engineered to withstand the rigors of transportation. Constructed from durable materials, it offers resistance to wear and environmental factors. Unique attributes such as its ergonomic shape and easy-to-use fastening system enhance its functionality, making it a reliable choice for securing truck parts 2.

Benefits

The advantages of using the 3282318 include improved safety during transit, as it minimizes the risk of component damage. Its design also facilitates ease of installation, reducing the time and effort required to secure parts for shipping. These benefits contribute to more efficient logistics and maintenance operations for commercial trucks 3.

Installation Process

Proper installation of the 3282318 involves several steps. First, identify the correct mounting points on the truck or trailer. Use the provided hardware to attach the bracket securely. Ensure that all fasteners are tightened to the manufacturer’s specifications to guarantee a firm hold. Following these steps will help in achieving a secure fitting that effectively protects the components during transport 4.

Maintenance and Care

To ensure the longevity and effectiveness of the 3282318, regular maintenance is recommended. This includes cleaning the bracket to remove any dirt or debris that could affect its performance. Inspecting for signs of wear or damage is also important, allowing for timely repairs or replacements. Adhering to these maintenance practices will help in preserving the bracket’s functionality over time 5.

Troubleshooting Common Issues

Common issues with the 3282318 may include loosening of fasteners or damage to the bracket itself. To address these problems, regularly check the tightness of all fasteners and replace any damaged components as needed. This proactive approach can prevent more serious issues from arising and ensure the continued reliability of the bracket 6.

Compatibility and Usage

The 3282318 is designed to work with specific types of trucks and components. It is important to verify compatibility to ensure optimal performance and safety. Considerations may include the size and weight of the components being transported, as well as the specific model of the truck or trailer 7.

Safety Considerations

Using the 3282318 involves several safety considerations. Proper handling and securement of the bracket during transport are crucial to prevent accidents or damage. Compliance with industry standards for transportation and securement of components is also important to ensure safety and regulatory compliance 8.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its commitment to quality and innovation. With a rich history of providing reliable and advanced truck components, Cummins plays a significant role in enhancing the performance and efficiency of commercial vehicles. The company’s dedication to excellence is evident in its wide range of products, including the 3282318 9.

Cummins Shipping Bracket 3282318 Compatibility

The Cummins Shipping Bracket part number 3282318 is designed to be compatible with a range of Cummins engines, ensuring secure mounting and alignment during transportation and installation. This bracket is crucial for maintaining the integrity of the engine during shipping and initial setup phases.

Compatibility with Specific Engine Models

-

6B5.9 and QSB5.9 Engines: The 3282318 is engineered to fit seamlessly with the 6B5.9 and QSB5.9 engines. These engines are known for their robust performance and reliability, often used in heavy-duty applications. The bracket ensures that these engines remain stable and properly aligned during transit, minimizing the risk of damage.

-

44 CM550 Engine: The 44 CM550 engine also benefits from the use of the 3282318. This engine is part of the Cummins lineup that is recognized for its efficiency and durability. The bracket’s design accommodates the specific mounting points and structural requirements of the 44 CM550, providing a secure fit that protects the engine from potential shifts or impacts during shipping.

By ensuring compatibility with these specific engine models, the 3282318 plays a vital role in the safe and efficient transportation of Cummins engines, facilitating smooth installation and operation in various applications.

Integration with Engine Components

Full Flow Oil Filter

The Full Flow Oil Filter is a key component in any engine system, responsible for removing contaminants from the engine oil to ensure smooth operation and longevity of the engine. The Shipping Bracket plays a significant role in securing the Full Flow Oil Filter during transit. By providing a stable mounting point, it prevents the filter from shifting or becoming dislodged, which could lead to damage or misalignment. This ensures that the filter is ready for immediate installation upon arrival, without the need for additional adjustments or repairs 10.

Oil Filter Housing

Often integrated with the Full Flow Oil Filter, the Oil Filter Housing is designed to contain the filter and facilitate the flow of oil through the filtration system. The Shipping Bracket helps in maintaining the alignment and stability of the Oil Filter Housing. This is particularly important for systems where the housing is pre-attached to other components. Secure fastening provided by the bracket prevents any potential damage that could compromise the seal or the structural integrity of the housing 11.

Engine Mounts and Brackets

In more complex engine systems, multiple mounts and brackets are used to secure various components in place. The Shipping Bracket complements these by offering additional support during transportation. It ensures that engine mounts and brackets remain in their designated positions, reducing the risk of misalignment or damage. This is especially beneficial in high-vibration environments typical during shipping, where unsecured components can shift and cause issues 12.

Auxiliary Components

Beyond the primary filtration system, engine systems often include auxiliary components such as sensors, gauges, and additional filtration media. The Shipping Bracket aids in securing these components, ensuring they arrive in optimal condition. This is vital for systems where precise placement and connection of these auxiliary components are necessary for the engine to function correctly 13.

Conclusion

In summary, the Cummins 3282318 Shipping Bracket is instrumental in maintaining the structural integrity and alignment of various engine components during transit. Its role in securing critical parts like the Full Flow Oil Filter and Oil Filter Housing, as well as supporting auxiliary components, ensures that engine systems are delivered in a state ready for immediate and efficient installation.

-

Majewski, Addy, and Hannu Jaskelainen. Diesel Emissions and Their Control: Second Edition. SAE International, 2023.

↩ -

Sheng, Gang. Vehicle Noise, Vibration and Sound Quality. SAE International, 2012.

↩ -

Genta, Giancarlo, and Lorenzo Morello. The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition. Springer, 2019.

↩ -

Harrison, Matthew. Controlling Noise and Vibration in Road Vehicles. SAE International, 2004.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 5613072, Engine: GTA38 G CMEICS G116C.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 5613072, Engine: GTA38 G CMEICS G116C.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 5613072, Engine: GTA38 G CMEICS G116C.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 5613072, Engine: GTA38 G CMEICS G116C.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 5613072, Engine: GTA38 G CMEICS G116C.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 5613072, Engine: GTA38 G CMEICS G116C.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 5613072, Engine: GTA38 G CMEICS G116C.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 5613072, Engine: GTA38 G CMEICS G116C.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 5613072, Engine: GTA38 G CMEICS G116C.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.