This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

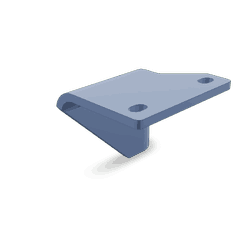

The Magnetic Switch Bracket, identified by Part #3287425, is a component manufactured by Cummins, a renowned leader in the automotive and heavy-duty truck industry. This Cummins part serves a specific purpose within the electrical systems of heavy-duty trucks, facilitating efficient and reliable operation .

Functionality of Magnetic Switch Bracket

The Magnetic Switch Bracket operates by securely holding the magnetic switch in place within the truck’s electrical system. This bracket ensures that the magnetic switch remains in the correct position to interact effectively with other electrical components. Its design allows for a stable connection, which is vital for the consistent performance of the electrical system. The bracket’s magnetic properties help in maintaining a firm grip on the switch, reducing the likelihood of disconnections or misalignments that could disrupt the electrical flow .

Role in Truck Operation

In the context of truck operation, the Magnetic Switch Bracket plays a role in ensuring the smooth functioning of the electrical system. By securely holding the magnetic switch, it contributes to the reliable activation and deactivation of various electrical circuits. This is particularly important in heavy-duty trucks, where the electrical system must operate under demanding conditions. The bracket’s role in maintaining the integrity of the electrical connections is fundamental to the truck’s overall performance and safety .

Key Features

The Magnetic Switch Bracket is characterized by several key features that enhance its performance. It is typically made from durable materials that can withstand the rigors of heavy-duty truck environments. The design of the bracket includes precise dimensions and a robust construction to ensure a secure fit for the magnetic switch. Additionally, the bracket may feature anti-corrosive coatings or treatments to protect against environmental factors that could degrade its performance over time.

Benefits

The advantages of using the Magnetic Switch Bracket include improved reliability of the electrical system, ease of installation, and maintenance benefits. Its secure hold on the magnetic switch reduces the risk of electrical failures due to loose connections. The design of the bracket also facilitates straightforward installation, minimizing downtime during maintenance procedures. Furthermore, its durable construction and protective coatings contribute to longevity and reduced need for frequent replacements.

Installation Process

Installing the Magnetic Switch Bracket involves several steps to ensure proper functionality. First, the area where the bracket will be mounted should be cleaned and prepared. The bracket is then positioned according to the manufacturer’s guidelines, ensuring it is aligned correctly with the magnetic switch and other electrical components. Secure the bracket in place using the provided fasteners, taking care to tighten them to the specified torque settings to avoid over-tightening, which could damage the bracket or the switch. Finally, verify the connection by testing the electrical system to confirm that the switch operates as intended.

Maintenance and Troubleshooting

Maintaining the Magnetic Switch Bracket involves regular inspections to ensure it remains securely attached and free from corrosion or damage. Common issues may include loosening of the fasteners or degradation of the bracket’s material. Troubleshooting steps include tightening any loose fasteners, cleaning the bracket and switch contacts to remove any buildup, and replacing the bracket if it shows signs of significant wear or damage. Regular maintenance helps in identifying potential issues before they lead to electrical system failures.

Safety Considerations

When working with the Magnetic Switch Bracket, it is important to observe safety guidelines to protect against electrical hazards. Ensure the truck’s electrical system is de-energized before beginning any installation or maintenance work. Use appropriate personal protective equipment, such as insulated gloves and safety glasses, to guard against electrical shocks and debris. Follow the manufacturer’s instructions carefully to avoid damaging the bracket or other electrical components. Additionally, be aware of the potential for stored energy in the electrical system, even when the truck is turned off, and take steps to discharge it safely before proceeding with any work.

Cummins Overview

Cummins is a well-established manufacturer with a strong reputation in the automotive and heavy-duty truck industry. The company has a history of innovation and commitment to quality, producing a wide range of components that are designed to meet the demanding requirements of commercial vehicles. Cummins’ products are known for their reliability, performance, and durability, making them a preferred choice among fleet operators and maintenance professionals. The company’s dedication to advancing technology and improving efficiency in the automotive sector underscores its position as a leader in the industry.

Role of Part 3287425 Magnetic Switch Bracket in Engine Systems

The 3287425 Magnetic Switch Bracket is integral to the seamless operation of various engine systems, particularly in the context of accessories and electric starting mechanisms.

In the realm of accessories, this bracket ensures the secure mounting of the magnetic switch, which is often connected to auxiliary systems such as lighting, heating, or cooling units. Its robust design allows for stable attachment, minimizing vibrations that could otherwise disrupt the function of these accessories.

For the electric starting system, the Magnetic Switch Bracket plays a significant role. It provides a firm foundation for the magnetic switch, which is a key component in the starting circuit. This ensures that the switch can reliably engage and disengage the starter motor, facilitating smooth engine startups. The bracket’s magnetic properties also help in reducing electrical resistance, enhancing the efficiency of the starting process.

Overall, the 3287425 Magnetic Switch Bracket contributes to the reliability and performance of engine systems by ensuring that critical components are securely and efficiently mounted.

Conclusion

The Magnetic Switch Bracket (Part #3287425) by Cummins is a vital component in the electrical systems of heavy-duty trucks and engines. Its robust design, ease of installation, and maintenance benefits make it an essential part for ensuring the reliable operation of electrical systems in demanding environments. Regular maintenance and adherence to safety guidelines are crucial for maximizing the performance and longevity of this part.

: Haoran Hu, Rudy Smaling, Simon Baseley, *Heavy-Duty Wheeled Vehicles*, SAE International, 2014.

: R. Matthew Brach, *SAE International's Dictionary of Vehicle Accident Reconstruction and Automotive Safety*, SAE Books, 2023.

: Rob Thompson, *Automotive Maintenance: Light Repair*, Cengage Learning, 2019.SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.