This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

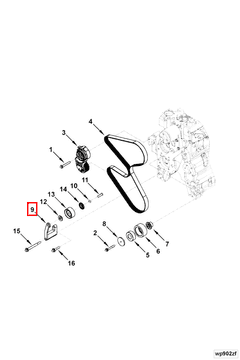

The 3288476 Idler Pulley Bracket, manufactured by Cummins, is a critical component in commercial trucks, designed to enhance the efficiency of the belt drive system. This bracket ensures the proper operation of various engine accessories by maintaining optimal belt tension and alignment.

Basic Concepts of Idler Pulley Brackets

An Idler Pulley Bracket functions as a mounting point for the idler pulley within a belt drive system. Its primary role is to maintain proper belt tension and alignment, which is essential for the smooth and efficient operation of the system 1. By interacting with belts and pulleys, it helps distribute the load evenly across the belt, reducing the risk of slippage or premature wear.

Purpose of the 3288476 Idler Pulley Bracket

This Cummins part is designed to maintain the correct tension and alignment of the belts in a truck’s engine system. Proper belt tension is crucial for the reliable operation of engine accessories such as alternators, water pumps, and air conditioning compressors. The 3288476 ensures that the belts run smoothly and efficiently, minimizing the risk of belt failure 2.

Key Features

The 3288476 Idler Pulley Bracket is constructed from durable materials to ensure longevity and reliability in demanding commercial truck environments. It features robust mounting options for secure attachment to the truck’s engine frame and includes precision-machined surfaces to ensure smooth operation of the idler pulley. Additionally, the bracket may incorporate vibration dampening elements to reduce noise and enhance system efficiency 3.

Benefits

This part offers several advantages. By maintaining optimal belt tension, it contributes to improved belt life and reduces the likelihood of belt failure. The precise alignment facilitated by the bracket minimizes belt wear and noise, leading to a quieter and more efficient operation of the belt drive system. Furthermore, the durable construction and high-quality materials used in the bracket enhance the overall reliability and performance of the truck’s engine accessories.

Installation Considerations

When installing the 3288476, it is important to follow guidelines to ensure proper alignment and tension. The installation process may require specific tools, such as torque wrenches, to secure the bracket and pulley correctly. Careful attention should be paid to the manufacturer’s instructions to avoid over-tightening or under-tightening, which can lead to belt issues. Ensuring that the bracket is level and securely mounted will contribute to the efficient operation of the belt drive system.

Troubleshooting Common Issues

Common problems associated with Idler Pulley Brackets include noise, wear, and misalignment. Noise can often be traced to improper tension or alignment, while wear may indicate a need for belt replacement or adjustment of the bracket. Misalignment can result from incorrect installation or wear on the bracket itself. Troubleshooting steps may involve inspecting the belt tension, checking the alignment of the pulleys, and ensuring that the bracket is securely mounted. Addressing these issues promptly can prevent more significant problems down the line.

Maintenance Tips

Routine maintenance of the 3288476 is important to ensure its continued reliable operation. Regular inspection intervals should be established to check for signs of wear or damage on the bracket and pulley. Lubrication requirements, if any, should be followed to keep moving parts operating smoothly. Additionally, monitoring the condition of the belts and ensuring they are properly tensioned will contribute to the longevity and efficiency of the belt drive system.

Cummins: Manufacturer Overview

Cummins Inc. is a well-established manufacturer with a strong reputation in the commercial truck industry. The company has a history of producing high-quality engine components and systems, known for their durability and performance. Cummins offers a wide range of products designed to meet the demanding requirements of commercial trucking, ensuring that their components contribute to the reliable and efficient operation of trucks in various applications.

Role of Part 3288476 Idler Pulley Bracket in Engine Systems

The 3288476 Idler Pulley Bracket is an integral component in maintaining the efficiency and reliability of various engine systems. It serves as a mounting point for the idler pulley, which is essential in the operation of the drive belt system.

In the context of the drive system, the idler pulley bracket ensures proper tension and alignment of the drive belt. This is vital for the seamless transfer of power from the engine to auxiliary components such as the alternator, air conditioning compressor, and power steering pump. The correct tension provided by the idler pulley, secured by the bracket, prevents slippage and ensures consistent performance of these components.

When considering the water pump, the idler pulley bracket plays a supportive role in the maintenance of the cooling system. The drive belt, tensioned by the idler pulley, powers the water pump, which circulates coolant through the engine to manage temperatures. A well-aligned and tensioned belt, facilitated by the idler pulley bracket, ensures the water pump operates efficiently, thereby maintaining optimal engine temperature and preventing overheating.

Conclusion

The 3288476 Idler Pulley Bracket is a key element in the drive system, directly influencing the performance of the water pump and other belt-driven components. Its role in maintaining belt tension and alignment is fundamental to the reliable operation of these engine systems. Regular maintenance and proper installation are essential to ensure the continued efficiency and reliability of the belt drive system.

-

Dixon, John C. Tyres Suspension and Handling Second Edition. SAE International, 1996.

↩ -

Kershaw, John F. SAE International’s Dictionary for Automotive Engineers. SAE International, 2023.

↩ -

Quigley, Jon M. SAE International’s Dictionary of Testing, Verification and Validation. SAE International, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.