3643014

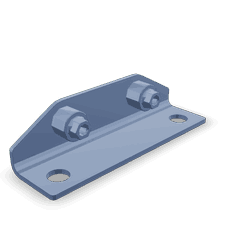

Vibration Isolator Bracket

Cummins®

AVAILABLE

1 is currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The 3643014 Vibration Isolator Bracket, designed by Cummins, addresses mechanical vibrations in commercial trucks. This component stabilizes various truck components, contributing to vehicle efficiency and reliability by mitigating the adverse effects of vibrations, which can lead to premature wear and reduced performance 3.

Basic Concepts of Vibration Isolator Brackets

A Vibration Isolator Bracket reduces the transmission of vibrations within a vehicle by providing a flexible mounting point that absorbs and dampens vibrations, preventing their spread throughout the truck’s structure. This is crucial in heavy-duty trucks, where vibrations can significantly impact the durability and performance of critical components 1.

Purpose of the 3643014 Vibration Isolator Bracket

The 3643014 Vibration Isolator Bracket is designed to reduce mechanical vibrations in commercial trucks. It stabilizes components such as engines, transmissions, and exhaust systems. By minimizing vibrations, this bracket maintains the alignment and integrity of these parts, ensuring they operate within their designed parameters and reducing the likelihood of premature failure 3.

Key Features

This Cummins part features a robust material composition, typically including high-strength alloys and polymers, which provide durability and resistance to wear. Its design incorporates elements such as flexible mounting points and vibration-dampening materials, which enhance its performance. Additionally, the bracket may include unique characteristics such as adjustable mounting options to accommodate various truck configurations and component sizes 3.

Benefits

The advantages provided by the 3643014 Vibration Isolator Bracket include improved component longevity, as reduced vibrations lead to less wear and tear on truck parts. Enhanced driver comfort is another benefit, as vibrations can cause discomfort and fatigue during long drives. Additionally, by ensuring components operate efficiently, this bracket may contribute to potential fuel efficiency gains, as stable components can lead to more consistent performance and reduced energy loss 3.

Installation Considerations

Proper installation of the 3643014 Vibration Isolator Bracket is crucial for its effective performance. Guidelines and best practices include ensuring the mounting surface is clean and free of debris, using the correct fasteners, and verifying that the bracket is securely attached. Preparatory steps may involve inspecting the area for any existing damage or wear that could affect the bracket’s performance. Tools required for installation typically include standard wrenches and possibly a torque wrench to ensure fasteners are tightened to the manufacturer’s specifications 3.

Troubleshooting Common Issues

Frequent problems associated with Vibration Isolator Brackets can include loosening of fasteners, wear on the bracket itself, or failure of the vibration-dampening materials. Suggested troubleshooting steps include regular inspections for signs of wear or damage, tightening fasteners as necessary, and replacing the bracket if it shows significant signs of degradation. Addressing these issues promptly can help maintain the bracket’s effectiveness and prevent more serious problems from developing 3.

Maintenance Tips

Regular maintenance of the 3643014 Vibration Isolator Bracket is important to ensure optimal performance and longevity. Recommendations include inspecting the bracket at regular intervals for signs of wear, corrosion, or damage. Care procedures may involve cleaning the bracket to remove any accumulated dirt or debris and lubricating moving parts if applicable. Following these maintenance tips can help extend the life of the bracket and ensure it continues to effectively reduce vibrations 3.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. Its product range includes a variety of components and systems designed to enhance the performance, efficiency, and reliability of commercial vehicles 2.

Role of Part 3643014 Vibration Isolator Bracket in Engine Systems

The 3643014 Vibration Isolator Bracket is integral to maintaining the stability and efficiency of various engine components. When integrated into an engine system, this bracket effectively mitigates vibrations that can be generated by the alternator.

In a typical engine arrangement, the alternator is responsible for generating electrical power to charge the battery and power the vehicle’s electrical systems. However, the operation of the alternator can produce vibrations that, if left unchecked, may affect the performance and longevity of surrounding components.

The 3643014 bracket is designed to absorb and isolate these vibrations, ensuring that the alternator operates smoothly without transmitting excessive vibrations to the engine block or other sensitive parts.

Additionally, the bracket often interfaces with the alternator guard, which serves to protect the alternator from physical damage and environmental factors. By securing the alternator guard in place, the bracket helps maintain the integrity of the alternator package, ensuring that all components within this package function optimally.

Overall, the 3643014 Vibration Isolator Bracket plays a significant role in enhancing the reliability and performance of the engine system by effectively managing vibrations and supporting the structural arrangement of key components 3.

Conclusion

The 3643014 Vibration Isolator Bracket by Cummins is a critical component in the maintenance and efficiency of commercial truck engines. By effectively managing vibrations, this part ensures the longevity and optimal performance of engine components, contributing to the overall reliability of the vehicle.

-

Minaker, B. P. (2019). Fundamentals of Vehicle Dynamics and Modelling. John Wiley Sons.

↩ -

Majewski, A., & Jaskelainen, H. (2023). Diesel Emissions and Their Control: Second Edition. SAE International.

↩ -

Boyce, M. P. (2011). Gas Turbine Engineering Handbook (4th ed.). Butterworth-Heinemann.

↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.