This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

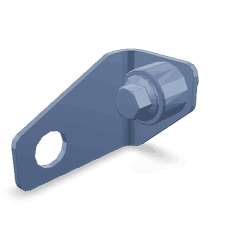

The Cummins 3643410 Vibration Isolator Bracket is a component designed to enhance the operational efficiency of commercial trucks. Its primary function is to mitigate vibrations emanating from the engine and drivetrain, contributing to a smoother ride and potentially extending the lifespan of various truck components.

Basic Concepts of Vibration Isolator Brackets

A Vibration Isolator Bracket serves to dampen the vibrations produced by the engine and other moving parts within a truck’s engine compartment. By securely mounting components while allowing for some degree of movement, these brackets help to absorb and dissipate vibrational energy, thereby reducing the impact of vibrations on the truck’s structure and its occupants 1.

Purpose of the 3643410 Vibration Isolator Bracket

The 3643410 Vibration Isolator Bracket is specifically engineered to reduce the transmission of engine and drivetrain vibrations to the truck’s frame. This reduction in vibration can lead to improved ride comfort for the driver and passengers, as well as decreased wear on the truck’s components, which may result in longer-lasting parts and potentially lower maintenance costs 2.

Key Features

The 3643410 Vibration Isolator Bracket is characterized by its robust design and the quality materials used in its construction. It is crafted to withstand the rigors of commercial truck operation, featuring a durable build that can handle significant vibrational forces. The bracket’s design may include features such as vibration-dampening pads or materials, which are integral to its function 3.

Benefits of Using the 3643410 Vibration Isolator Bracket

Utilizing the 3643410 Vibration Isolator Bracket can lead to several advantages. These include an enhanced ride comfort due to reduced vibrations, which can be particularly noticeable at higher speeds or over rough terrain. Additionally, by minimizing the vibrational forces transmitted to the truck’s components, the bracket may contribute to a reduction in wear and tear, potentially leading to extended component lifespan and improved overall truck performance 4.

Installation Process

Installing the 3643410 Vibration Isolator Bracket involves several steps to ensure it is properly secured and functions as intended. The process typically requires specific tools and may involve removing existing brackets or components to make way for the new installation. Careful attention to alignment and securing the bracket firmly in place is crucial to its effectiveness.

Troubleshooting Common Issues

Common issues with the 3643410 Vibration Isolator Bracket may include improper installation, which can lead to continued vibrations or even damage to the bracket itself. Troubleshooting steps may involve re-evaluating the installation process, ensuring all fasteners are tightened to the manufacturer’s specifications, and checking for any signs of wear or damage that could indicate a need for replacement.

Maintenance Tips

To ensure the optimal performance and longevity of the 3643410 Vibration Isolator Bracket, regular maintenance is recommended. This includes periodic inspections for signs of wear, damage, or loosening of fasteners. Depending on the operating conditions and the truck’s usage, replacement guidelines may vary, but adhering to the manufacturer’s recommendations can help maintain the bracket’s effectiveness.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product offerings are designed to meet the diverse needs of its customers, providing reliable and efficient power solutions for various applications.

Cummins Engine Compatibility with Part 3643410

The Vibration Isolator Bracket, part number 3643410, manufactured by Cummins, is designed to mitigate engine vibrations, ensuring smoother operation and longevity of the engine. This part is compatible with several Cummins engine models, specifically the QSK45 CM500, QSK60 CM500, QSK60 CM850 MCRS, and QSK78 CM500.

For the QSK45 CM500 and QSK60 CM500 engines, the Vibration Isolator Bracket is engineered to fit seamlessly, providing a stable mounting point that reduces the transfer of vibrations from the engine to the chassis. This is particularly important in maintaining the structural integrity of the vehicle and enhancing the overall driving experience.

In the case of the QSK60 CM850 MCRS and QSK78 CM500 engines, the bracket’s design accommodates the increased power output and operational demands of these higher-capacity engines. The bracket’s robust construction ensures it can handle the additional stress and vibrations generated by these engines, contributing to their reliable performance.

The compatibility of the Vibration Isolator Bracket across these engines underscores its versatility and importance in the Cummins engine lineup. By effectively managing engine vibrations, this component plays a vital role in the overall efficiency and durability of the engines it supports.

Role of Part 3643410 Vibration Isolator Bracket in Engine Systems

The part 3643410 Vibration Isolator Bracket is a component in the assembly and operation of various engine systems. Its primary function is to mitigate vibrations that are generated by the engine’s operation, ensuring smoother and more efficient performance of interconnected components.

Integration with Compressor Guard

When integrated with the compressor guard, the Vibration Isolator Bracket plays a significant role in maintaining the structural integrity and operational efficiency of the compressor. By reducing vibrations, it helps prevent undue stress on the compressor guard, which is vital for protecting internal components from damage due to debris or accidental contact. This ensures that the compressor operates within optimal parameters, enhancing its longevity and reliability.

Role in Package Assembly

In the context of a packaged engine system, the Vibration Isolator Bracket is instrumental in maintaining the balance and stability of the entire assembly. It helps in evenly distributing the vibrational forces across the package, which is essential for the proper functioning of all enclosed components. This is particularly important in packaged systems where space is limited, and components are in close proximity to each other. The bracket ensures that vibrations do not lead to misalignment or damage to other parts within the package.

Interaction with Guard Components

The Vibration Isolator Bracket also interacts effectively with various guard components within the engine system. Guards are often used to protect sensitive parts from environmental factors and operational wear. By isolating vibrations, the bracket ensures that these guards remain firmly in place and do not become dislodged or damaged over time. This is essential for maintaining the protective integrity of the guard components, ensuring they continue to shield critical engine parts from harm.

Conclusion

In summary, the 3643410 Vibration Isolator Bracket is a key component in enhancing the performance and durability of engine systems by effectively managing vibrational forces. Its integration with compressor guards, packaged assemblies, and other guard components underscores its importance in maintaining the overall efficiency and reliability of the engine.

-

Bartz, Wilfried J. Engine Oils and Automotive Lubrication Mechanical Engineering Book 80. CRC Press, 2019.

↩ -

Gifford, Clive. Cars Encyclopedia. DK Publishing, 2014.

↩ -

Bonnick, Allan. A Practical Approach to Motor Vehicle Engineering and Maintenance. Elsevier, 2004.

↩ -

Aird, Forbes. Bosch Fuel Injection Systems. HP Books, 2001.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.