3965124

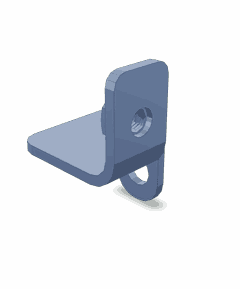

Wiring Retainer Bracket

Cummins®

IN STOCK

4 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3965124 Wiring Retainer Bracket is a component designed to secure and organize wiring harnesses within heavy-duty truck electrical systems. Its role is significant in maintaining the integrity and efficiency of electrical connections, ensuring that the truck’s electrical system operates reliably and safely 1.

Purpose and Function

The Wiring Retainer Bracket serves to secure and organize wiring harnesses, which are bundles of electrical wires that transmit power and signals throughout the truck. By holding the harnesses in place, the bracket helps prevent wires from becoming tangled, damaged, or disconnected. This organization contributes to maintaining the integrity and efficiency of electrical connections, which is vital for the proper functioning of the truck’s electrical system 2.

Key Features

This Cummins part is constructed with durable materials to withstand the harsh conditions often encountered in heavy-duty truck environments. Its design includes features such as mounting options that allow for flexible installation in various truck models. The bracket’s unique characteristics enhance its performance and durability, ensuring long-term reliability in securing wiring harnesses 3.

Benefits

Using the Wiring Retainer Bracket offers several advantages. It improves wire management by keeping harnesses organized and secured, which reduces the risk of electrical faults caused by loose or damaged wires. Additionally, the bracket enhances overall system reliability by ensuring that electrical connections remain intact and functional, contributing to the truck’s safe and efficient operation 4.

Installation and Compatibility

Proper installation of this part involves following specific guidelines to ensure it is securely mounted and effectively holds the wiring harnesses in place. Compatibility with various truck models and electrical systems is an important consideration, ensuring that the bracket can be used across different applications without requiring significant modifications 5.

Maintenance and Troubleshooting

Routine maintenance of the Wiring Retainer Bracket involves inspecting it for signs of wear or damage and ensuring that it remains securely mounted. Troubleshooting common issues related to wiring harness management and electrical connections may involve checking for loose connections, damaged wires, or signs of electrical arcing, and addressing these issues promptly to maintain system integrity 6.

Safety Considerations

When working with electrical components and the Wiring Retainer Bracket, it is important to adhere to safety precautions and best practices. This includes following manufacturer guidelines, using appropriate personal protective equipment, and ensuring that the electrical system is de-energized when performing maintenance or repairs. Adhering to industry standards and regulations is crucial for ensuring the safety of personnel and the reliability of the truck’s electrical system 7.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a strong reputation in the automotive and heavy-duty truck industries, Cummins offers a wide range of products designed to meet the demanding requirements of these sectors. The company’s commitment to quality and performance is evident in its extensive product offerings, which include components like the Wiring Retainer Bracket 3965124 8.

Application in Cummins Engines

ISC CM554 and ISL CM554 Engines

The Wiring Retainer Bracket 3965124 is specifically engineered to fit the ISC CM554 and ISL CM554 engines. These engines are known for their robust performance and reliability, often used in heavy-duty applications such as construction equipment, trucks, and industrial machinery. The bracket ensures that the wiring harness is properly anchored, preventing it from becoming dislodged or damaged due to vibrations or movement 9.

QSC8.3 CM554 and QSL9 CM554 Engines

Similarly, the bracket is also compatible with the QSC8.3 CM554 and QSL9 CM554 engines. These engines are designed for high-performance applications, often found in on-highway and off-highway vehicles. The bracket’s design allows for easy installation and adjustment, ensuring that the wiring harness remains secure and organized, which is crucial for the efficient operation of these engines 10.

Importance of the Wiring Retainer Bracket

The proper installation of the Wiring Retainer Bracket 3965124 is vital for several reasons:

- Protection of Wiring Harness: By securing the wiring harness, the bracket prevents potential damage that could lead to electrical failures.

- Organization: It helps in keeping the wiring tidy and accessible, which is beneficial for maintenance and troubleshooting.

- Vibration Resistance: The bracket’s design ensures that the wiring harness remains in place even under high vibration conditions, which is common in engine environments 11.

Installation Considerations

When installing the Wiring Retainer Bracket 3965124, it is important to follow the manufacturer’s guidelines to ensure proper fit and function. This includes:

- Correct Positioning: Ensuring the bracket is placed in the designated location to provide maximum support.

- Secure Fastening: Using appropriate fasteners to attach the bracket firmly to the engine block.

- Regular Inspection: Periodically checking the bracket for any signs of wear or damage and replacing it if necessary 12.

By adhering to these guidelines, the Wiring Retainer Bracket 3965124 will effectively contribute to the longevity and reliability of the engine’s electrical system.

Role of Part 3965124 Wiring Retainer Bracket in Engine Systems

The part 3965124 Wiring Retainer Bracket is an essential component in organizing and securing various wiring systems within engine assemblies. Its primary function is to maintain the integrity and order of the wiring, ensuring that all connections remain secure and protected from potential damage 13.

Integration with Fuel Pressure Sensor Kit

When integrating with the fuel pressure sensor kit, the Wiring Retainer Bracket plays a significant role in securing the sensor’s wiring. This ensures that the sensor can accurately measure fuel pressure without interference from loose or damaged wires. The bracket helps in maintaining a stable connection, which is vital for the sensor’s reliable operation and the overall performance of the fuel system 14.

Coordination with Harness

The Wiring Retainer Bracket is instrumental in coordinating with the harness by keeping the wiring organized and protected. This is particularly important in high-vibration environments typical of engine compartments. By securing the harness, the bracket prevents chafing and potential short circuits, thereby enhancing the durability and reliability of the electrical system 15.

Support for Electronic Control Module Wiring

In the context of electronic control module (ECM) wiring, the Wiring Retainer Bracket provides necessary support to keep the wiring neat and untangled. This is essential for the ECM to receive accurate data from various sensors and to send precise commands to the actuators. The bracket ensures that the wiring remains in optimal condition, facilitating efficient communication within the engine’s electronic systems 16.

Compatibility with Sensor Kit

When used with a sensor kit, the Wiring Retainer Bracket ensures that all sensor wires are properly managed. This is important for maintaining the accuracy and responsiveness of the sensors. By securing the wires, the bracket helps in preventing any potential issues that could arise from loose or damaged connections, thereby ensuring that the sensor kit functions as intended 17.

Conclusion

The Cummins 3965124 Wiring Retainer Bracket is a vital component in the maintenance and operation of heavy-duty truck electrical systems. Its role in securing and organizing wiring harnesses ensures the integrity and efficiency of electrical connections, contributing to the reliable and safe operation of the truck. Proper installation, maintenance, and adherence to safety considerations are essential for maximizing the benefits of this part.

-

Nunney, MJ. Light and Heavy Vehicle Technology, Fourth Edition. Butterworth-Heinemann, 2007.

↩ -

Reif, Konrad Ed. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Sobey, Ed. A Field Guide to Automotive Technology. Chicago Review Press, 2009.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 4388664, QSK95 CM2350 K113.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 4388664, QSK95 CM2350 K113.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 4388664, QSK95 CM2350 K113.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 4388664, QSK95 CM2350 K113.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 4388664, QSK95 CM2350 K113.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 4388664, QSK95 CM2350 K113.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 4388664, QSK95 CM2350 K113.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 4388664, QSK95 CM2350 K113.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 4388664, QSK95 CM2350 K113.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 4388664, QSK95 CM2350 K113.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 4388664, QSK95 CM2350 K113.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 4388664, QSK95 CM2350 K113.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 4388664, QSK95 CM2350 K113.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 4388664, QSK95 CM2350 K113.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.