This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

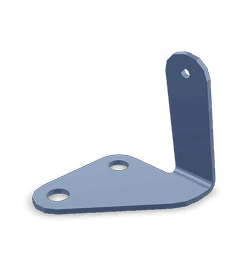

The Cummins 5293174 Wiring Retainer Bracket is a component designed to secure and organize wiring harnesses within the electrical system of commercial trucks. Its role is significant in maintaining the integrity and efficiency of the truck’s electrical infrastructure, which is vital for the overall performance and safety of the vehicle 1.

Purpose and Function

The Wiring Retainer Bracket serves to hold wiring harnesses in place, ensuring they remain organized and protected within the truck’s engine compartment. By securing the wiring, it helps prevent chafing, abrasion, and potential damage from moving parts or vibrations. This function is integral to maintaining the reliability of the electrical connections and reducing the risk of electrical faults that could lead to system failures 2.

Key Features

The design of the Cummins 5293174 incorporates several features that enhance its performance and durability. Constructed from high-strength materials, it is built to withstand the harsh conditions found in commercial truck environments. Its design allows for easy attachment and adjustment, facilitating a secure fit around the wiring harnesses. Additionally, the bracket’s material is resistant to corrosion and extreme temperatures, ensuring long-term reliability 3.

Benefits

The use of the Wiring Retainer Bracket offers several advantages. It improves wire management by keeping harnesses neatly organized and away from potential damage sources. This organization reduces the likelihood of electrical faults, contributing to the overall safety and reliability of the truck’s electrical system. Furthermore, by securing the wiring, it helps maintain consistent electrical connections, which is crucial for the proper functioning of various truck systems 4.

Installation and Usage

Proper installation of the Wiring Retainer Bracket is key to ensuring its effectiveness. It should be securely fastened to the truck’s frame or designated mounting points, following the manufacturer’s guidelines. Care should be taken to ensure that the wiring is not twisted or overly tightened, as this could lead to damage. Regular checks should be performed to ensure the bracket remains securely attached and the wiring is in good condition.

Maintenance and Troubleshooting

To maintain the Wiring Retainer Bracket, regular inspections are recommended to ensure it remains in good condition and securely attached. Any signs of wear, corrosion, or damage should be addressed promptly to prevent potential issues. Common troubleshooting steps include checking for loose connections, ensuring the bracket is properly secured, and verifying that the wiring is not damaged or frayed.

Manufacturer Information

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its wide range of diesel engines and related components. With a history of innovation and quality, Cummins has established a strong reputation for producing reliable and high-performance parts. The company’s product range includes engines, filtration systems, emissions solutions, and aftermarket parts, all designed to meet the demanding requirements of commercial trucking.

Compatibility

This part is engineered to fit seamlessly with various Cummins engine models, ensuring optimal performance and reliability.

ISB6.7 and CM2350 Engines

This Cummins part is specifically compatible with the ISB6.7 and CM2350 engines. These engines are known for their robust performance and are widely used in various applications, including heavy-duty trucks and industrial machinery. The bracket’s design allows for efficient management of the complex wiring systems found in these engines, reducing the risk of damage and ensuring that all electrical connections remain secure.

B101 Engine

The B101 engine also benefits from the use of the Wiring Retainer Bracket 5293174. This engine is typically used in agricultural and construction equipment, where durability and reliability are paramount. The bracket’s precise fit ensures that the wiring is properly managed, enhancing the engine’s overall performance and longevity.

Grouping by Application

In addition to individual engine compatibility, the Wiring Retainer Bracket 5293174 is also grouped by application. For instance, it is suitable for use in:

- Heavy-Duty Trucks: Ensuring that the wiring is securely managed in the demanding environments of long-haul trucking.

- Industrial Machinery: Providing a reliable solution for the complex wiring needs of industrial equipment.

- Agricultural Equipment: Offering durability and ease of maintenance for the rigorous conditions of farming and construction.

By fitting seamlessly with these engines and applications, the Wiring Retainer Bracket 5293174 plays a crucial role in maintaining the integrity of the electrical systems within Cummins engines.

Role of 5293174 in Engine Systems

The 5293174 plays a role in organizing and securing the Electronic Control Module (ECM) Wiring Harness within various engine systems. This part ensures that the wiring harness is properly positioned and protected from potential damage caused by engine vibrations, heat, or moving parts.

When integrating the 5293174 with the ECM Wiring Harness, it is important to consider the following aspects:

-

Secure Mounting: The bracket provides a stable mounting point for the harness, reducing the risk of wires becoming dislodged or frayed over time. This is particularly important in high-vibration environments typical of engine compartments.

-

Thermal Protection: By keeping the wiring harness away from direct contact with hot engine components, the bracket helps maintain the integrity of the wires and insulation, ensuring reliable performance of the ECM.

-

Space Management: The bracket assists in managing the available space within the engine bay, allowing for efficient routing of the harness without interference with other components. This is vital for maintaining a tidy and organized engine compartment.

-

Maintenance Accessibility: Proper installation of the bracket facilitates easier access to the wiring harness for inspection, diagnosis, and repairs. This can significantly reduce downtime during maintenance procedures.

-

Integration with Other Systems: The 5293174 often works in conjunction with other brackets and mounting points to create a comprehensive wiring management system. This holistic approach ensures that all wiring components are securely held in place, contributing to the overall reliability of the engine system.

Conclusion

The Cummins 5293174 Wiring Retainer Bracket is a vital component in the electrical system of commercial trucks, ensuring the secure and organized management of wiring harnesses. Its robust design, compatibility with various Cummins engines, and role in maintaining the integrity of electrical connections contribute to the overall performance, safety, and reliability of the vehicle.

-

Bonnick, A. (2004). A Practical Approach to Motor Vehicle Engineering and Maintenance. Elsevier.

↩ -

Sobey, E. (2009). A Field Guide to Automotive Technology. Chicago Review Press.

↩ -

Hilgers, M. (2023). Electrical Systems and Mechatronics, Second Edition. Springer Vieweg.

↩ -

Norman, A. (2016). Diesel Technology Fundamentals Service Repair Eighth Edition. The Goodheart-Willcox Company Inc.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.