This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

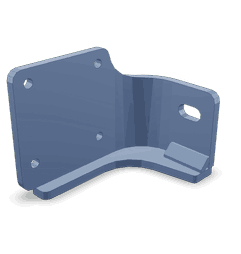

The Cummins Marine Gear Bracket, part number 5294300, is a critical component designed for integration with specific Cummins marine engines. Cummins, a reputable manufacturer in the commercial truck industry, is known for producing a wide range of parts and systems that contribute to the efficiency and reliability of commercial vehicles. This part is engineered to ensure robust and reliable performance in marine environments, where durability and precision are paramount 1.

Purpose and Function

For the QSB6.7 M CM2250 engine, the Marine Gear Bracket plays a pivotal role in the engine’s operation. It is specifically tailored to fit the unique design and requirements of this engine model, ensuring that it can withstand the rigors of marine use. The bracket is integral to the engine’s gear system, providing the necessary support and alignment for smooth and efficient operation 2.

Key Features

The Marine Gear Bracket is constructed from high-quality materials that resist corrosion and can endure the demanding conditions of marine use. Its design ensures that it fits snugly and securely, minimizing the risk of misalignment or failure under load. This bracket’s robust construction and the use of corrosion-resistant materials enhance its longevity and reliability in demanding environments 3.

Benefits

The use of the Marine Gear Bracket offers several advantages. It contributes to improved stability of the marine gear within the transmission system, leading to enhanced performance and reliability of the engine. Additionally, its durable construction can result in potential cost savings for operators by reducing the need for frequent replacements or repairs. The bracket’s design also aids in maintaining the efficiency of the drivetrain, which can contribute to overall fuel economy 4.

Installation Process

Proper installation of the Marine Gear Bracket is crucial for ensuring optimal performance and longevity. The process involves securing the bracket to the transmission housing using the appropriate fasteners, ensuring that the marine gear is properly aligned. It is important to follow manufacturer guidelines for torque specifications and to verify that all connections are secure. Careful attention to these details during installation will help maintain the integrity of the drivetrain system.

Common Issues and Troubleshooting

Typical problems that may arise with the Marine Gear Bracket include misalignment, wear, or damage due to environmental factors. Troubleshooting steps may involve inspecting the bracket for signs of wear or damage, ensuring that all fasteners are secure, and verifying the alignment of the marine gear. Regular maintenance and inspections can help identify and address issues before they lead to more significant problems.

Maintenance Guidelines

To ensure continued reliable operation, the Marine Gear Bracket should be included in the regular maintenance schedule for the engine. This includes periodic inspections for signs of wear or damage, cleaning to remove any debris or contaminants, and verifying the tightness of all fasteners. Replacement guidelines should be followed if the bracket shows significant wear or if it has been damaged.

Conclusion

The Cummins Marine Gear Bracket, part number 5294300, is a fundamental component that enhances the support and functionality of the power train in marine engine systems. Its role in maintaining alignment, reducing vibrations, and ensuring efficient power transfer underscores its importance in the overall performance and reliability of marine propulsion systems. Proper installation, regular maintenance, and adherence to manufacturer guidelines are essential for maximizing the benefits of this part.

-

Lakshminarayanan, P. A., & Nayak, N. S. (2011). Critical Component Wear in Heavy Duty Engines. John Wiley & Sons.

↩ -

Drozdziel, P. (2023). The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects. Routledge.

↩ -

Fischer, R., Kucukay, F., Jurgens, G., Najork, R., & Pollak, B. (2015). The Automotive Transmission Book Powertrain. Springer.

↩ -

Ferrari, A., & Pizzo, P. (2022). Injection Technologies: Mixture Formation Strategies. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.