This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

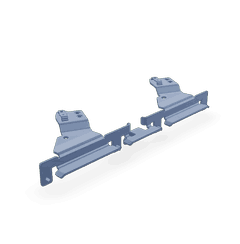

The 5372875 Wiring Retainer Bracket by Cummins is a component designed to secure and organize wiring harnesses within heavy-duty trucks. Its role is significant in maintaining the integrity and efficiency of the truck’s electrical system, ensuring that wires remain protected and properly routed throughout the vehicle.

Basic Concepts of Wiring Retainer Brackets

A Wiring Retainer Bracket is a device used in vehicle electrical systems to hold and organize wiring harnesses. It plays a role in preventing wires from coming into contact with moving parts or sharp edges, which could lead to damage. Additionally, it helps in maintaining a tidy and accessible wiring layout, which is crucial for both maintenance and repair operations 1.

Purpose of the 5372875 Wiring Retainer Bracket

This Cummins part is specifically designed to secure and organize wiring harnesses in the electrical system of a truck. It plays a role in keeping wires in place, reducing the risk of chafing or abrasion against other components. This bracket contributes to the overall operation of the truck by ensuring that the electrical connections remain intact and function as intended.

Key Features

The 5372875 features a robust material composition, typically made from durable plastics or metals, ensuring it can withstand the rigors of heavy-duty truck environments. Its design includes elements such as mounting points and clips that allow for secure attachment to the truck’s frame and wiring harnesses. Additionally, the bracket may have unique characteristics such as corrosion-resistant coatings or flexible mounting options to enhance its performance and durability 2.

Benefits

This part offers several benefits, including improved wire management which leads to a more organized and accessible electrical system. It reduces the risk of electrical faults by keeping wires away from potential damage sources. Furthermore, its durable construction ensures it can withstand harsh operating conditions, contributing to the longevity and reliability of the truck’s electrical system.

Installation Process

Installing the 5372875 involves several steps to ensure secure and effective placement. Begin by identifying the appropriate location on the truck’s frame where the bracket will be mounted. Use the provided mounting hardware to attach the bracket securely. Next, route the wiring harnesses through the bracket, ensuring they are properly secured using the built-in clips or ties. Finally, double-check all connections to ensure they are tight and the wires are not under tension.

Troubleshooting Common Issues

Common problems associated with Wiring Retainer Brackets include loose connections or damaged brackets. To address these issues, inspect the bracket and its mounting points for any signs of wear or damage. Tighten any loose connections and replace any damaged components as necessary. Regularly check the condition of the wiring harnesses to ensure they are not chafing or showing signs of wear 3.

Maintenance Tips

To ensure the longevity and optimal performance of the 5372875, regular maintenance is recommended. This includes routine inspections to check for any signs of wear or damage to the bracket and wiring harnesses. Cleaning the bracket and surrounding areas can prevent the buildup of dirt and debris, which could lead to corrosion or other issues. Additionally, ensuring that all connections remain tight and secure will help maintain the integrity of the electrical system.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for its commitment to quality and innovation. The company offers a wide range of products designed to meet the demanding needs of heavy-duty applications, ensuring reliability and performance in various operating conditions 4.

Role of Part 5372875 Wiring Retainer Bracket in Engine Systems

In the intricate network of an engine system, the 5372875 serves a significant function by ensuring the secure and organized placement of various wiring components. This bracket is instrumental in maintaining the integrity and efficiency of the Electronic Control Module (ECM) Wiring Harness and the overall harness system.

Integration with ECM Wiring Harness

The ECM Wiring Harness is a complex assembly of wires that connects the Electronic Control Module to various sensors and actuators throughout the engine system. The 5372875 plays a key role here by holding the harness in place, preventing it from moving or vibrating excessively. This stability is essential for maintaining consistent electrical connections, which are vital for the accurate transmission of data and signals between the ECM and other engine components 5.

Supporting the Harness System

Beyond the ECM Wiring Harness, the 5372875 also supports the broader harness system within the engine. This includes securing wires that supply power to ignition systems, fuel injectors, and other critical components. By keeping these wires organized and protected, the bracket helps in reducing the risk of electrical shorts or damage due to abrasion against moving parts within the engine compartment.

Enhancing System Reliability

The organized and secure placement of wiring, facilitated by the 5372875, contributes to the overall reliability of the engine system. It ensures that all electrical connections remain intact under various operating conditions, from normal driving to more strenuous situations like off-roading or high-performance driving. This reliability is paramount in preventing unexpected failures and ensuring the engine operates smoothly and efficiently.

Conclusion

In summary, the 5372875 Wiring Retainer Bracket is a vital component in the engine system, providing the necessary support and organization for the ECM Wiring Harness and the broader harness system. Its role in maintaining secure and stable wiring connections is fundamental to the efficient and reliable operation of the engine.

-

Crolla, David. Crolla Encyclopedia. Wiley, 2015.

↩ -

Watson, Ben. Mobile Equipment Hydraulics A Systems and Troubleshooting Approach. Cengage Learning, 2011.

↩ -

Hilgers, Michael. Alternative Powertrains and Extensions to the Conventional Powertrain. Springer Nature, 2023.

↩ -

Reif, Konrad Ed. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Cummins Inc. B6.7 CM2350 B148B and B6.7 CM2450 B217B Stop-Start Applications, Service Manual (5411262).

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.