This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

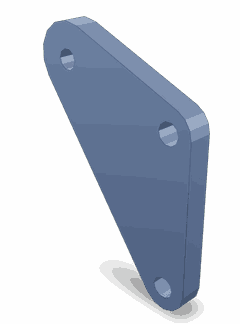

The Idler Pulley Mounting Bracket, identified by Part #3287300, is a component manufactured by Cummins, a leading name in the automotive and heavy-duty truck industry. This bracket plays a role in the functionality and efficiency of heavy-duty trucks, particularly within the engine compartment.

Basic Concepts

The Idler Pulley Mounting Bracket is integral to the belt drive system found in heavy-duty trucks. It serves as a mounting point for the idler pulley, which is a component that helps maintain the proper tension and alignment of the belts that drive various engine accessories. The bracket ensures that the idler pulley is correctly positioned and securely held in place, allowing it to perform its role effectively within the engine compartment 1.

Purpose and Function

The Idler Pulley Mounting Bracket contributes to the operation of a truck by supporting the idler pulley, which in turn helps maintain the correct tension and alignment of the belts. Proper belt tension is important for the efficient transfer of power to engine accessories such as the alternator, water pump, and air conditioning compressor. By ensuring that the belts are properly tensioned and aligned, the bracket helps prevent slippage, reduce wear, and enhance the overall performance and reliability of the engine 2.

Key Features

The Idler Pulley Mounting Bracket is characterized by its durable construction and precise engineering. It is designed to withstand the rigors of heavy-duty truck operation, providing a stable and secure mounting point for the idler pulley. The bracket is compatible with various Cummins engine models, ensuring a proper fit and function within the engine compartment.

Benefits

The use of the Idler Pulley Mounting Bracket offers several advantages. It contributes to improved engine performance by ensuring that the belts driving engine accessories are properly tensioned and aligned. This reduces wear on the belts and pulleys, leading to longer service life and reduced maintenance costs. Additionally, the bracket enhances the reliability of the engine in demanding operating conditions, providing peace of mind to truck operators and fleet managers 3.

Installation and Compatibility

Proper installation of the Idler Pulley Mounting Bracket is important for its effective function. It may require specific tools and procedures to ensure a secure and correct fit within the engine compartment. The bracket is compatible with various Cummins engine models, providing flexibility for fleet managers and maintenance professionals.

Maintenance and Troubleshooting

Regular maintenance of the Idler Pulley Mounting Bracket is important to ensure optimal performance. This includes periodic inspection for signs of wear or damage, and addressing any issues promptly to prevent further complications. Common troubleshooting steps may involve checking the alignment and tension of the belts, and ensuring that the bracket and idler pulley are securely mounted and functioning correctly.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the automotive industry. The company’s product offerings cater to various applications, from on-highway and off-highway to industrial and power generation, providing solutions that meet the diverse needs of customers worldwide.

Idler Pulley Mounting Bracket (Part 3287300) Compatibility with Cummins Engines

The Idler Pulley Mounting Bracket, part number 3287300, is a component in the engine assembly, designed to secure the idler pulley in place. This part is engineered to fit various Cummins engines, ensuring proper alignment and function of the engine’s belt system. Below is a detailed description of its compatibility with different Cummins engine models:

B Series Engines

- 6B5.9

- B5.6 CM2670 B152B

- B6.7 CM2670 B153B

The Idler Pulley Mounting Bracket is compatible with the B series engines, including the 6B5.9, B5.6 CM2670 B152B, and B6.7 CM2670 B153B. These engines are known for their robust design and reliability, often used in heavy-duty applications.

G Series Engines

- B6.7 G CMOH6.0 B125

This bracket fits the B6.7 G CMOH6.0 B125 engine, which is part of the G series. This engine is designed for high-performance applications, and the bracket ensures the idler pulley is correctly positioned to maintain belt tension and efficiency.

ISB/ISD Series Engines

- ISB/ISD4.5 CM2150 B119

- ISB/ISD6.7 CM2150 SN

The Idler Pulley Mounting Bracket is also compatible with the ISB/ISD series engines, including the ISB/ISD4.5 CM2150 B119 and ISB/ISD6.7 CM2150 SN. These engines are widely used in various industries due to their durability and efficiency.

ISB5.9 Series Engines

- ISB5.9 CM2880 B110

- ISB5.9 CM2880 B140

- ISB5.9 CM2880 B149

- ISB5.9G CM2180

The bracket fits the ISB5.9 series engines, which include the ISB5.9 CM2880 B110, ISB5.9 CM2880 B140, ISB5.9 CM2880 B149, and ISB5.9G CM2180. These engines are known for their power and reliability, making them suitable for a wide range of applications.

ISBE Series Engines

- ISBE CM2150

- ISBE CM800

- ISBE4 CM850

The Idler Pulley Mounting Bracket is also compatible with the ISBE series engines, including the ISBE CM2150, ISBE CM800, and ISBE4 CM850. These engines are designed for high-performance and are often used in demanding environments.

QSB6.7 Series Engine

- QSB6.7 CM850 (CM2850)

Lastly, the bracket fits the QSB6.7 CM850 (CM2850) engine, which is part of the QSB series. This engine is known for its efficiency and reliability, making it a popular choice for various applications.

This comprehensive compatibility ensures that the Idler Pulley Mounting Bracket can be used across a wide range of Cummins engines, providing a reliable solution for maintaining the integrity of the engine’s belt system.

Role of Part 3287300 Idler Pulley Mounting Bracket in Engine Systems

The 3287300 Idler Pulley Mounting Bracket is a component in maintaining the alignment and tension of various engine drive systems. It securely mounts the idler pulley, which plays a role in the efficient operation of the alternator drive and water pump drive systems.

Alternator Drive System

In the alternator drive system, the 3287300 Idler Pulley Mounting Bracket ensures that the idler pulley is correctly positioned. This positioning is important for maintaining the proper tension on the drive belt that connects the alternator to the engine’s crankshaft. The correct tension ensures that the alternator operates efficiently, generating the necessary electrical power for the vehicle’s electrical systems without slippage or excessive wear on the belt.

Water Pump Drive System

Similarly, in the water pump drive system, the 3287300 Idler Pulley Mounting Bracket helps in maintaining the alignment and tension of the drive belt that powers the water pump. The water pump is responsible for circulating coolant through the engine to prevent overheating. Proper belt tension, facilitated by the idler pulley mounted on this bracket, ensures that the water pump operates smoothly and effectively, providing consistent coolant flow and protecting the engine from thermal damage.

Overall Engine Performance

By ensuring the correct alignment and tension of the drive belts in both the alternator and water pump systems, the 3287300 Idler Pulley Mounting Bracket contributes to the overall performance and reliability of the engine. It helps in reducing wear and tear on the belts and pulleys, thereby extending the lifespan of these components and enhancing the engine’s efficiency.

Conclusion

The Idler Pulley Mounting Bracket, part number 3287300, is a critical component in the maintenance and efficiency of heavy-duty truck engines. Its role in ensuring proper belt tension and alignment contributes to the reliable operation of engine accessories, reduces maintenance costs, and enhances overall engine performance. With its compatibility across various Cummins engine models, this Cummins part provides a versatile solution for fleet managers and maintenance professionals.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.