This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

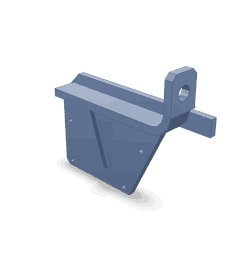

The 3326154 Idler Pulley Bracket, manufactured by Cummins, is a component designed for use in heavy-duty truck maintenance and operation. Cummins, a well-established name in the automotive and heavy-duty truck industry, produces this part to enhance the efficiency and reliability of truck engines. The Idler Pulley Bracket is integral to the belt drive system, ensuring optimal performance and longevity of the truck’s engine components.

Basic Concepts of Idler Pulley Brackets

An Idler Pulley Bracket serves as a mounting point for the idler pulley within the belt drive system of a vehicle. Its primary function is to maintain the correct tension and alignment of the belts that drive various engine accessories, such as the alternator, water pump, and air conditioning compressor. By interacting with belts, tensioners, and pulleys, the idler pulley bracket ensures smooth and efficient operation of these components 1.

Purpose of the 3326154 Idler Pulley Bracket

The 3326154 Idler Pulley Bracket plays a role in the operation of a truck by maintaining proper belt tension and alignment. This ensures that the belts run smoothly and efficiently, reducing the risk of slippage or breakage. Proper tension and alignment are vital for the consistent performance of engine accessories, contributing to the overall reliability and efficiency of the truck’s engine 2.

Key Features

The 3326154 Idler Pulley Bracket is constructed from high-quality materials, ensuring durability and resistance to wear and corrosion. Its design includes precise mounting points and alignment features to facilitate easy installation and accurate belt tensioning. Additionally, the bracket may incorporate unique attributes such as vibration dampening elements to enhance performance and reduce noise 3.

Benefits

Using the 3326154 Idler Pulley Bracket offers several benefits. It contributes to improved belt life by ensuring consistent tension and alignment, reducing the frequency of belt replacements. Additionally, it lowers maintenance requirements by minimizing the need for adjustments and repairs. Enhanced overall engine performance is another advantage, as properly tensioned and aligned belts lead to more efficient operation of engine accessories 4.

Installation Process

Installing the 3326154 Idler Pulley Bracket requires careful attention to detail to ensure correct fitting. The process involves securing the bracket to the engine block using the provided fasteners, positioning the idler pulley, and adjusting the belt tension to the manufacturer’s specifications. Tools required may include a torque wrench for tightening fasteners to the correct specifications and a belt tension gauge for accurate tension adjustment.

Troubleshooting Common Issues

Common problems associated with Idler Pulley Brackets include noise, wear, or misalignment. Noise may indicate improper belt tension or a worn pulley, while wear can result from excessive friction or misalignment. To troubleshoot these issues, inspect the belt for signs of wear or damage, check the tension using a belt tension gauge, and ensure the pulley is properly aligned and free of obstructions.

Maintenance Tips

Regular maintenance practices are essential to ensure the longevity and optimal performance of the 3326154 Idler Pulley Bracket. Inspect the bracket and associated components during routine engine checks, looking for signs of wear, corrosion, or misalignment. Replace worn or damaged parts as necessary, and adjust belt tension according to the manufacturer’s recommendations to maintain efficient operation.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and customer satisfaction in the automotive and heavy-duty truck industry. The company’s commitment to excellence is reflected in its diverse product range, which includes engines, powertrains, and aftermarket parts designed to meet the demanding requirements of modern transportation and power generation applications.

Idler Pulley Bracket 3326154 Compatibility with Cummins Engines

The Idler Pulley Bracket part number 3326154, manufactured by Cummins, is designed to fit seamlessly with various Cummins engine models. This bracket is a critical component in the engine’s belt drive system, ensuring proper tension and alignment of the serpentine belt.

NH/NT 855 Engines

The Idler Pulley Bracket 3326154 is compatible with the NH/NT 855 engines. This bracket ensures that the belt system operates efficiently, maintaining the correct tension and alignment of the pulleys. The NH/NT 855 engines are known for their robust design and reliability, making the 3326154 bracket an essential part for maintaining engine performance.

QSNT14 CM876 N102 Engines

Similarly, the Idler Pulley Bracket 3326154 is also suitable for the QSNT14 CM876 N102 engines. This bracket plays a crucial role in the belt drive system of these engines, ensuring that the belt remains properly tensioned and aligned. The QSNT14 CM876 N102 engines are designed for high performance and durability, and the 3326154 bracket is engineered to meet these demands.

Grouping of Compatible Engines

The Idler Pulley Bracket 3326154 is engineered to fit a range of Cummins engines, including but not limited to the NH/NT 855 and QSNT14 CM876 N102 models. This compatibility is due to the standardized design and specifications of the bracket, which ensures it can be used across multiple engine types. Cummins has designed this bracket to provide a reliable and efficient solution for maintaining the belt drive system in their engines.

Role of Part 3326154 Idler Pulley Bracket in Engine Systems

The 3326154 Idler Pulley Bracket is an integral component in the orchestration of various engine systems, ensuring the seamless operation of several key elements.

Drive System Integration

In the drive system, the 3326154 Idler Pulley Bracket supports the idler pulley, which maintains tension in the belt drive system. This tension is essential for the efficient transfer of power from the engine to auxiliary components such as the alternator, water pump, and air conditioning compressor. The bracket’s precise positioning and secure mounting allow for consistent belt tension, reducing wear and tear on the belt and enhancing the longevity of the drive system components.

Fan System Functionality

Within the fan system, the 3326154 Idler Pulley Bracket plays a significant role by supporting the fan idler pulley. This pulley is responsible for adjusting the fan’s position relative to the engine, optimizing airflow over the radiator for effective cooling. The bracket ensures that the idler pulley remains stable and aligned, which is vital for the fan to operate at the correct angle and speed. This alignment is particularly important during varying engine loads and speeds, ensuring that the engine maintains an optimal operating temperature.

Pivot Bracket Interaction

The interaction between the 3326154 Idler Pulley Bracket and the pivot bracket is another area where this component proves its worth. The pivot bracket often serves as a mounting point for the fan assembly, allowing it to pivot and adjust as needed. The idler pulley bracket works in conjunction with the pivot bracket to provide a stable and adjustable platform for the fan idler pulley. This collaboration ensures that the fan can move freely while remaining securely attached, which is essential for dynamic cooling requirements and engine performance.

Conclusion

The 3326154 Idler Pulley Bracket is a key player in maintaining the integrity and efficiency of the drive, fan, and pivot bracket systems within an engine. Its role in supporting and aligning critical components ensures that these systems operate harmoniously, contributing to the overall performance and reliability of the engine.

-

Sander, F. (2007). Diesel Mechanics, First Edition. Global Media.

↩ -

Giles, T. (2019). Automotive Engines Diagnosis Repair and Rebuilding. Cengage Learning.

↩ -

Boyce, M. P. (2002). Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing.

↩ -

Cummins Inc. (n.d.). ISF2.8 CM2220 F122, Service Manual (5467376).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.