This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins Instrument Panel Mounting Bracket, part number 3053012, is a component designed for commercial trucks. Cummins, a well-established manufacturer in the automotive industry, produces this bracket to ensure the secure attachment of the instrument panel within the vehicle. This part is integral to the structural integrity and operational efficiency of the truck’s dashboard area.

Basic Concepts of Instrument Panel Mounting Brackets

An Instrument Panel Mounting Bracket serves as a foundational support for the instrument panel within a vehicle. Its primary function is to securely hold the instrument panel in place, ensuring it remains stable during operation. This bracket integrates with various components such as the dashboard frame, wiring harnesses, and mounting points. Typically, these brackets are manufactured using durable materials like steel or aluminum, chosen for their strength and resistance to wear and corrosion 1.

Purpose of the Cummins Instrument Panel Mounting Bracket

The Cummins Instrument Panel Mounting Bracket, part number 3053012, plays a role in supporting the instrument panel of a truck. It ensures that the panel remains firmly in position, which is vital for the proper functioning of the vehicle’s dashboard components. This bracket contributes to the overall safety and functionality of the truck by maintaining the structural integrity of the instrument panel, thereby ensuring that all gauges and controls are accessible and operational under various driving conditions.

Key Features

The Cummins Instrument Panel Mounting Bracket features a design that includes precision-engineered mounting points and robust construction. It is made from high-quality materials that offer excellent durability and resistance to the stresses encountered in commercial truck environments. The bracket’s design allows for easy installation and integration with the truck’s existing dashboard structure, ensuring a secure fit.

Benefits

Using the Cummins Instrument Panel Mounting Bracket offers several advantages. It provides enhanced stability for the instrument panel, which is crucial for maintaining the integrity of the dashboard during operation. This stability contributes to improved safety by ensuring that all controls and gauges remain accessible and functional. Additionally, the secure mounting can lead to increased driver comfort and ease of use, as the instrument panel remains in its intended position.

Installation Process

Installing the Cummins Instrument Panel Mounting Bracket involves several steps. First, ensure that the dashboard area is clean and free of any obstructions. Next, align the bracket with the designated mounting points on the dashboard frame. Use the appropriate tools to secure the bracket in place, following the manufacturer’s guidelines for torque specifications. Finally, double-check the installation to ensure that the bracket is firmly attached and that the instrument panel is properly supported.

Troubleshooting and Maintenance

Common issues with the Cummins Instrument Panel Mounting Bracket may include loose connections or corrosion at the mounting points. To address these issues, regularly inspect the bracket for signs of wear or damage. Tighten any loose fasteners and clean the mounting area to prevent corrosion. Maintaining the bracket in good condition will ensure the longevity and optimal performance of the instrument panel support system.

Compatibility and Applications

The Cummins Instrument Panel Mounting Bracket is designed for specific types of trucks and models. It is important to verify compatibility with the truck’s make and model to ensure proper fit and function. In some cases, modifications may be necessary to accommodate different dashboard configurations. Always consult the manufacturer’s guidelines for any specific considerations or requirements.

Cummins: Manufacturer Overview

Cummins is a reputable manufacturer with a long-standing history in the automotive industry. Known for their commitment to quality and innovation, Cummins produces a wide range of components designed to enhance the performance and reliability of commercial vehicles. Their products are engineered to meet the demanding requirements of heavy-duty applications, ensuring durability and efficiency in various operating conditions 2.

Cummins Instrument Panel Mounting Bracket 3053012 Compatibility

The Cummins Instrument Panel Mounting Bracket, part number 3053012, is designed to be compatible with a range of Cummins engines, ensuring a secure and reliable mounting solution for the instrument panel. This bracket is engineered to fit seamlessly with various engine models, providing a robust connection that enhances operational efficiency and safety.

Compatible Engines

-

K19, K38, K50: These engines benefit from the bracket’s precision fit, ensuring that the instrument panel is securely mounted and easily accessible for maintenance and monitoring.

-

M11 MECHANICAL, N14 MECHANICAL: The bracket’s design accommodates the unique layout and mounting requirements of these mechanical engines, facilitating straightforward installation and reliable operation.

-

NH/NT 855: This bracket is engineered to integrate with the NH/NT 855 engine, providing a stable mounting solution that supports the instrument panel’s functionality and durability.

-

QSK19 CM500, V28: The Cummins Instrument Panel Mounting Bracket 3053012 is also compatible with the QSK19 CM500 and V28 engines. Its design ensures that the instrument panel is securely mounted, enhancing the overall performance and ease of use of these engines.

The bracket’s compatibility with these engines underscores Cummins’ commitment to providing high-quality, reliable components that meet the diverse needs of their customers.

Integration of Part 3053012 Instrument Panel Mounting Bracket with Engine Systems

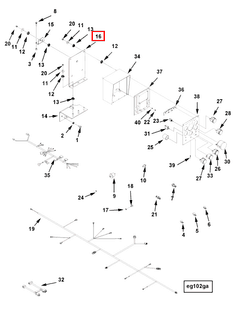

The Cummins Instrument Panel Mounting Bracket, part number 3053012, is integral to the assembly and secure positioning of the Instrument Panel within engine systems. This bracket interfaces directly with the Instrument Panel Enclosure, ensuring that the Instrument Panel is held firmly in place. It supports the Instrument Panel Enclosure, which houses sensitive engine instruments and gauges, providing a stable platform for accurate readings and operation.

In conjunction with the Enclosure Mounting Bracket, the Cummins Instrument Panel Mounting Bracket ensures that the entire Instrument Panel assembly is securely attached to the engine’s structure. This setup is essential for maintaining the integrity of the Instrument Panel Enclosure and protecting the internal components from vibrations and external impacts.

Furthermore, the Cummins Instrument Panel Mounting Bracket plays a role in the alignment and integration of the Instrument Panel with other engine components such as the Belt Guard and Enclosure. By providing a robust mounting solution, it allows for the Instrument Panel to be easily accessed for maintenance or adjustments while ensuring that it remains securely fastened during engine operation.

The bracket’s design also facilitates the connection between the Instrument Panel and the Engine Instrument systems, allowing for seamless data transmission and display. This integration is vital for the overall functionality and reliability of the engine’s monitoring and control systems 3.

Conclusion

The Cummins Instrument Panel Mounting Bracket, part number 3053012, is a critical component for the secure and reliable mounting of the instrument panel in commercial trucks. Its robust design, compatibility with various Cummins engines, and integration with engine systems ensure the stability and functionality of the dashboard. Regular maintenance and proper installation are essential to maximize the benefits of this part, contributing to the overall safety and performance of the vehicle.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.