This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins Instrument Panel Bracket, part number 3328382, is a component designed for commercial trucks, playing a role in the overall functionality of a truck’s dashboard by providing a secure mounting point for various dashboard components. Understanding the function and importance of instrument panel brackets is key to maintaining the operational integrity of a truck’s dashboard.

Basic Concepts of Instrument Panel Brackets

An instrument panel bracket serves as a structural support for the dashboard of a vehicle. It integrates with other components of the dashboard to hold gauges, controls, and displays in place. These brackets are typically made from materials such as steel, aluminum, or plastic, chosen for their strength, durability, and resistance to environmental factors. The material selection impacts the bracket’s ability to withstand vibrations, temperature fluctuations, and physical stress 1.

Purpose of the 3328382 Instrument Panel Bracket

This Cummins part is specifically designed to support and secure various dashboard components in commercial trucks. It ensures that gauges, controls, and displays remain firmly in place, contributing to the driver’s ability to monitor and operate the vehicle effectively. This bracket plays a role in maintaining the structural integrity of the dashboard, which is subject to vibrations and movements during operation.

Key Features

The 3328382 features a design that maximizes stability and durability. Constructed from high-quality materials, it includes precise mounting points that ensure a secure fit. Its design may incorporate features that enhance functionality, such as adjustable mounting options or corrosion-resistant coatings, contributing to its longevity and performance in various operating conditions.

Benefits

The installation of this part offers several benefits. It contributes to improved dashboard stability, ensuring that all mounted components remain secure during operation. This security enhances safety by preventing components from becoming dislodged or damaged. Additionally, a well-designed bracket can contribute to the aesthetic appeal of the truck’s interior, providing a clean and professional look.

Installation Process

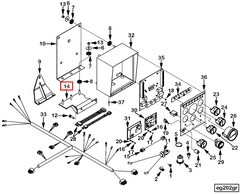

Installing the 3328382 involves several steps to ensure a proper fit and secure attachment. Preparatory steps may include cleaning the mounting area and ensuring that all necessary tools are available. The installation process requires careful alignment with the dashboard’s mounting points, followed by securing the bracket in place using the provided fasteners. Tips for a successful installation include double-checking the alignment before tightening fasteners and ensuring that all components are securely attached.

Troubleshooting and Maintenance

Common issues with instrument panel brackets may include loose fittings or damage due to wear and tear. Troubleshooting steps involve inspecting the bracket and its mounting points for signs of wear, ensuring that all fasteners are tight, and replacing any damaged components as necessary. Regular maintenance, such as checking for corrosion and ensuring that all connections are secure, can help prolong the life and functionality of the 3328382 2.

Cummins: Manufacturer Overview

Cummins Inc. is a well-established manufacturer in the commercial truck industry, known for its commitment to quality and innovation. With a broad product range that includes engines, filtration systems, and aftermarket parts, Cummins has built a reputation for reliability and performance. The company’s dedication to advancing technology and meeting the needs of its customers underscores its position as a leader in the industry.

Role of the 3328382 in Engine Systems

This part is an integral component in the assembly and functionality of engine systems. It provides a secure mounting point for the instrument panel, ensuring that all gauges, indicators, and controls are properly aligned and accessible to the operator. This bracket is designed to withstand the vibrations and stresses inherent in engine operation, maintaining the structural integrity of the instrument panel.

In engine systems, the Instrument Panel Bracket interfaces with various components to facilitate efficient operation and monitoring. It supports the engine instrument cluster, which includes essential gauges such as the tachometer, speedometer, fuel gauge, and temperature indicators. These gauges rely on the stability provided by the bracket to deliver accurate readings, allowing for precise monitoring of engine performance and conditions.

Additionally, the bracket plays a role in the organization and accessibility of control switches and buttons. It ensures that these controls are within easy reach of the operator, promoting safe and effective management of engine functions. The bracket also aids in the routing of wiring harnesses, helping to keep cables organized and protected from damage, which is vital for the reliable transmission of data and power between the engine instruments and the engine control unit (ECU).

Furthermore, the Instrument Panel Bracket contributes to the overall aesthetic and ergonomic design of the engine compartment. By providing a sturdy foundation for the instrument panel, it allows for a clean and professional installation, enhancing the visual appeal and usability of the engine system. This attention to detail not only improves the operator’s experience but also reflects the quality and craftsmanship of the engine’s design.

Conclusion

The 3328382 Instrument Panel Bracket is a vital component in the maintenance and operation of commercial trucks, ensuring the stability and accessibility of dashboard components. Its design and functionality contribute to the safety, efficiency, and aesthetic appeal of the vehicle’s interior. Regular maintenance and proper installation are essential to maximize the benefits of this part, reflecting Cummins’ commitment to quality and innovation in the commercial truck industry.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.