This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

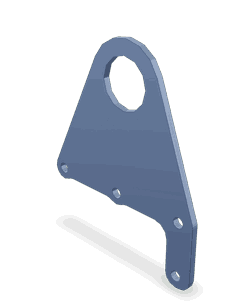

The 3883586 Lifting Bracket, manufactured by Cummins, is a specialized component designed for use in commercial trucks. Cummins, a well-established name in the commercial truck industry, produces a range of high-quality components that enhance the performance and reliability of heavy-duty vehicles. This part is integral to the maintenance and operational efficiency of commercial trucks, facilitating the safe handling and securing of heavy components during repair and maintenance procedures.

Basic Concepts of Lifting Brackets

Lifting brackets are mechanical devices used across various automotive and industrial applications to support and secure components during maintenance or repair. They function by providing a stable and secure point for lifting equipment to attach, ensuring that the component being lifted is held firmly in place. This reduces the risk of accidents and damage to both the component and the vehicle 1.

Purpose of the 3883586 Lifting Bracket

The 3883586 Lifting Bracket is specifically designed to play a role in the operation and maintenance of commercial trucks by aiding in the safe lifting and securing of heavy components. Its design allows for efficient and secure attachment to lifting equipment, ensuring that components are handled with precision and care. This is particularly important in heavy-duty truck maintenance, where the weight and size of components can pose significant challenges 2.

Key Features

This Cummins part is constructed from high-quality materials, ensuring durability and effectiveness in demanding environments. Its design incorporates several elements that enhance its performance, including reinforced attachment points and a robust frame that can withstand significant loads. Additionally, the bracket features a unique design that allows for easy attachment and detachment, streamlining the maintenance process.

Benefits

Using the 3883586 Lifting Bracket offers several advantages. It enhances safety during lifting operations by providing a secure attachment point for lifting equipment. Its durable construction ensures long-term reliability, reducing the need for frequent replacements. Moreover, the efficient design of the bracket can lead to potential cost savings over time by minimizing downtime and the risk of damage to components during maintenance.

Installation and Usage

Proper installation and usage of the 3883586 Lifting Bracket are crucial for ensuring its effectiveness and safety. It is important to follow manufacturer guidelines for installation, which may include securing the bracket to the vehicle frame and ensuring that all attachment points are properly aligned. Safety protocols should be observed during use, including the use of appropriate lifting equipment and ensuring that the bracket is securely attached before lifting any components 3.

Troubleshooting and Maintenance

Regular inspections and maintenance are key to ensuring the longevity and reliability of the 3883586 Lifting Bracket. Common issues may include wear and tear on attachment points or damage to the bracket itself. Troubleshooting these issues typically involves a thorough inspection of the bracket and its attachment points, followed by any necessary repairs or replacements. Maintenance routines should include cleaning the bracket and checking for any signs of damage or wear.

Cummins: Manufacturer Overview

Cummins Inc. is a global leader in the design, manufacture, and distribution of engines and related technologies. With a history spanning over a century, Cummins has established a reputation for producing high-quality, reliable components for the commercial truck industry. Their product range includes engines, filtration systems, and aftermarket parts, all designed to enhance the performance and efficiency of heavy-duty vehicles. Cummins’ commitment to quality and innovation makes them a trusted source for truck components, including the 3883586 Lifting Bracket.

Cummins Engine Part 3883586: Lifting Bracket Compatibility

The Cummins part 3883586, a Lifting Bracket, is designed to be compatible with a range of Cummins engines, ensuring secure and reliable lifting operations. This part is engineered to fit seamlessly with the following engines:

ISM Series Engines

- ISM CM570

- ISM CM570/870

- ISM CM876

- ISM11 CM876 SN

The ISM series engines are known for their robust performance and reliability, making them suitable for various heavy-duty applications. The Lifting Bracket part 3883586 is specifically designed to fit these engines, providing a secure attachment point for lifting equipment.

L10 Series Engines

- L10 CELECT

- L10 GAS

- L10 MECHANICAL

The L10 series engines are engineered for high efficiency and durability, often used in both marine and industrial applications. The Lifting Bracket part 3883586 is compatible with these engines, ensuring that the lifting process is both safe and efficient.

M11 Series Engines

- M11 CELECT

- M11 CELECT PLUS

- M11 MECHANICAL

The M11 series engines are designed for superior performance and reliability, making them ideal for a wide range of applications. The Lifting Bracket part 3883586 is engineered to fit these engines, providing a reliable solution for lifting operations.

QSM11 Series Engines

- QSM11 CM570

- QSM11 CM876

The QSM11 series engines are known for their advanced technology and performance. The Lifting Bracket part 3883586 is compatible with these engines, ensuring that the lifting process is both secure and efficient.

By using the Cummins part 3883586, technicians and operators can ensure that their lifting operations are performed safely and effectively, regardless of the specific engine model.

Role of Part 3883586 Lifting Bracket in Engine Systems

The Lifting Bracket (Part 3883586) is an integral component in the arrangement and handling of various engine systems. Its primary function is to provide a secure and stable point for lifting and maneuvering heavy engine components during installation, maintenance, or removal processes.

When integrated into an engine system, the Lifting Bracket is typically attached to specific points on the engine block or other substantial components. This ensures that the weight is evenly distributed, minimizing the risk of damage to the engine during lifting operations.

In conjunction with other lifting equipment, such as cranes or hoists, the Lifting Bracket allows for precise control and stability. This is particularly important when dealing with complex engine arrangements where multiple components need to be aligned accurately.

The Lifting Bracket also plays a significant role in the safety protocols of engine maintenance. By providing a designated lifting point, it reduces the likelihood of accidents caused by improper lifting techniques. This is essential in high-stakes environments where engine reliability and safety are paramount.

Furthermore, the use of the Lifting Bracket simplifies the process of rearranging engine components. Whether it’s for routine maintenance or major overhauls, having a reliable lifting point speeds up the process and enhances efficiency.

Conclusion

In summary, the Lifting Bracket (Part 3883586) is a fundamental element in the safe and effective handling of engine systems, contributing to both the integrity of the engine and the safety of the personnel involved. Its compatibility with a range of Cummins engines, combined with its robust design and ease of use, makes it an invaluable component in the maintenance and operation of commercial trucks.

-

Boyce, M. P. (2002). Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing.

↩ -

Dixon, J. (2014). Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning.

↩ -

Atkins, R. D. (2009). An Introduction to Engine Testing and Development. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.