3062483

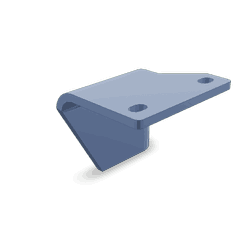

Magnetic Switch Bracket

Cummins®

AVAILABLE

2 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins Magnetic Switch Bracket, identified by part number 3062483, is designed to facilitate the mounting and operation of magnetic switches in commercial trucks. This part ensures the proper functioning of these switches, contributing to the overall reliability and performance of the vehicle.

Basic Concepts and Functionality

Magnetic switch brackets operate on the principle of magnetism, allowing for the secure attachment of magnetic switches to metallic surfaces within the truck. These switches are used in conjunction with sensors and other electronic components to monitor and control various systems, such as engine functions, lighting, and auxiliary equipment. The magnetic property of the bracket ensures a stable and vibration-resistant connection, which is essential in the dynamic environment of a commercial truck 1.

Purpose and Role in Truck Operation

The Cummins Magnetic Switch Bracket provides a stable platform for magnetic switches, enabling functions such as engine start/stop, lighting control, and monitoring of various systems. The bracket ensures that the switches remain securely in place, even under the harsh conditions typically experienced by commercial trucks, thus contributing to the efficient and reliable operation of the vehicle 2.

Key Features

The Cummins Magnetic Switch Bracket is characterized by several key features that enhance its functionality and durability. Its design incorporates high-strength materials to withstand the rigors of truck operation. The bracket is engineered to provide a strong magnetic hold, ensuring that the switches remain firmly attached. Additionally, it is designed for easy installation and compatibility with a range of magnetic switches, making it a versatile component for various truck models.

Benefits

The advantages provided by the Cummins Magnetic Switch Bracket include improved efficiency and reliability in the operation of truck systems. By securely mounting magnetic switches, the bracket helps to prevent issues such as switch detachment or malfunction, which can lead to system failures. Furthermore, the robust design of the bracket contributes to the longevity of the switches and the overall system, reducing the need for frequent replacements or repairs.

Installation Process

Installing the Cummins Magnetic Switch Bracket involves several steps to ensure proper attachment and functionality. First, identify the appropriate mounting location on the truck’s metallic surface. Next, align the bracket with the surface and press firmly to establish a magnetic connection. Ensure that the bracket is level and securely attached before proceeding to mount the magnetic switch. Use the appropriate tools to connect the switch to the bracket and verify that all connections are secure and functioning correctly.

Troubleshooting Common Issues

Common problems that may arise with the Cummins Magnetic Switch Bracket include weak magnetic hold or switch malfunction. To address these issues, first, check the condition of the mounting surface for any debris or corrosion that may interfere with the magnetic connection. Clean the surface if necessary and reattach the bracket. If the switch is not functioning correctly, verify the electrical connections and ensure that the switch is compatible with the bracket. Consult the manufacturer’s guidelines for further troubleshooting steps if needed.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins Magnetic Switch Bracket, regular maintenance practices should be observed. Inspect the bracket and mounting surface periodically for signs of wear or damage. Clean the surface to remove any buildup that may affect the magnetic hold. Additionally, check the electrical connections to the switch for corrosion or loose fittings and address any issues promptly to prevent system failures.

Safety Considerations

When working with the Cummins Magnetic Switch Bracket, it is important to observe safety protocols and precautions. Ensure that the truck is turned off and the key is removed before beginning any installation or maintenance procedures. Use appropriate personal protective equipment, such as gloves and safety glasses, to protect against potential hazards. Follow the manufacturer’s instructions carefully to avoid damage to the bracket or switch and to ensure safe and effective operation.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the commercial truck industry. The company’s commitment to excellence is reflected in its wide range of products, including the Cummins Magnetic Switch Bracket, which is designed to meet the demanding requirements of commercial truck applications 3.

Compatibility with Cummins Engines

The Magnetic Switch Bracket part number 3062483, manufactured by Cummins, is designed to fit a variety of Cummins engines. This bracket plays a role in the engine’s ignition system by ensuring the magnetic switch is properly positioned and secured.

K-Series Engines

- K19

- K38

- K50

These K-series engines benefit from the precise alignment provided by the Magnetic Switch Bracket, ensuring reliable engine operation.

KTA19 Series Engines

- KTA19GC

- KTA19GC CM558

The KTA19GC and KTA19GC CM558 engines are equipped with the Magnetic Switch Bracket to maintain the integrity of the ignition system.

M11 Series Engines

- M11 CELECT PLUS

- M11 MECHANICAL

Both the M11 CELECT PLUS and M11 MECHANICAL engines utilize the Magnetic Switch Bracket to secure the magnetic switch, ensuring consistent performance.

N14 Series Engines

- N14 MECHANICAL

The N14 MECHANICAL engine relies on the Magnetic Switch Bracket for proper positioning of the magnetic switch, contributing to the engine’s overall reliability.

NH/NT Series Engines

- NH/NT 855

The NH/NT 855 engine incorporates the Magnetic Switch Bracket to maintain the alignment of the magnetic switch, ensuring smooth engine operation.

QSK19 Series Engines

- QSK19 CM2350 K114

- QSK19 CM2350 K144G

- QSK19 CM500

- QSK19 CM850 MCRS

- QSK19G

- QSK45 CM500

- QSK60 CM500

These QSK19 series engines, including the QSK45 and QSK60 variants, all use the Magnetic Switch Bracket to ensure the magnetic switch is correctly positioned.

QSM11 Series Engines

- QSM11 CM570

The QSM11 CM570 engine employs the Magnetic Switch Bracket to maintain the alignment of the magnetic switch, contributing to the engine’s performance.

QSNT14 Series Engines

- QSNT14 CM876 N102

The QSNT14 CM876 N102 engine uses the Magnetic Switch Bracket to secure the magnetic switch, ensuring reliable ignition system operation.

QST30 Series Engines

- QST30 CM2350 T101

- QST30 CM552

Both the QST30 CM2350 T101 and QST30 CM552 engines are equipped with the Magnetic Switch Bracket to maintain the proper positioning of the magnetic switch.

QSX15 Series Engines

- QSX15 CM2250 ECF

The QSX15 CM2250 ECF engine utilizes the Magnetic Switch Bracket to ensure the magnetic switch is correctly aligned.

V28 Series Engines

- V28

The V28 engine incorporates the Magnetic Switch Bracket to maintain the alignment of the magnetic switch, ensuring consistent engine performance.

Role of Part 3062483 Magnetic Switch Bracket in Engine Systems

The Magnetic Switch Bracket, identified as part 3062483, is an integral component in various engine systems, particularly those involving electric starting mechanisms. This part is designed to securely mount the magnetic switch, ensuring stable and reliable operation of the electric starting system.

Integration with Electric Starting Systems

In electric starting systems, the Magnetic Switch Bracket is used to affix the magnetic switch to the engine or its surrounding structure. This secure mounting is essential for the proper functioning of the starter, as it ensures that the magnetic switch remains in the correct position to engage with the starter solenoid. The bracket’s design allows for easy installation and adjustment, facilitating a smooth integration with the starter and other electrical components.

Compatibility with Accessories and Instrument Panel Mounting

The Magnetic Switch Bracket is often found in systems that include accessories like air starting and electric starting components. It is compatible with instrument panel mounting systems, allowing for organized and accessible placement of the magnetic switch. This is particularly important in systems where space is at a premium, ensuring that all components are neatly arranged without compromising functionality.

Use in Dual Delco-Remy 24V Start Systems

In dual Delco-Remy 24V start systems, the Magnetic Switch Bracket plays a significant role in maintaining the structural integrity of the starting mechanism. By securely holding the magnetic switch in place, it ensures that the dual starting system operates efficiently, providing reliable starts even in demanding conditions.

Electrical System Kit and Instrument Panel Integration

When incorporated into an electrical system kit, the Magnetic Switch Bracket aids in the systematic organization of various electrical components. It is often paired with instrument panel mounting brackets to create a cohesive and well-structured electrical setup. This integration enhances the overall reliability and maintainability of the engine’s electrical system.

Application in 12 Volt Starter Systems

For 12 Volt starter systems, the Magnetic Switch Bracket ensures that the magnetic switch is correctly positioned to interact with the starter motor. This is vital for the consistent and effective operation of the starting system, particularly in environments where precision and reliability are paramount.

Summary of Component Interactions

- Accessories: The bracket facilitates the secure mounting of magnetic switches in various accessory systems, ensuring they function correctly.

- Air Starting and Electric Starting: It provides a stable platform for magnetic switches in both air and electric starting systems.

- Electrical Systems: Enhances the organization and reliability of electrical components within the system.

- Instrument Panel Mounting: Allows for neat and accessible placement of magnetic switches on instrument panels.

- Dual Delco-Remy 24V Start: Ensures the structural integrity and efficient operation of dual starting systems.

- 12 Volt Starter: Critical for the precise engagement of magnetic switches with 12 Volt starters.

Conclusion

The Cummins Magnetic Switch Bracket (part number 3062483) is a vital component in the operation and reliability of commercial truck systems. Its design and functionality ensure the secure and efficient mounting of magnetic switches, contributing to the overall performance and longevity of the vehicle. Regular maintenance and proper installation are essential to maximize the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.