3068915

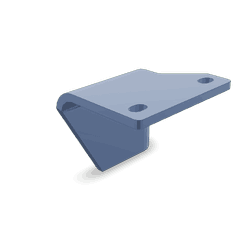

Magnetic Switch Bracket

Cummins®

AVAILABLE

3 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Magnetic Switch Bracket (Part #3068915) by Cummins is a specialized component designed for use in commercial trucks. It serves a specific purpose within the truck’s electrical system, facilitating the operation of various electrical components. This part is integral to ensuring the reliable and efficient functioning of the truck’s electrical circuits.

Basic Concepts

Magnetic switch brackets operate on the principle of magnetism to control electrical circuits. They are designed to open and close circuits based on the presence or absence of a magnetic field. In truck systems, these brackets are used to manage the flow of electricity to different components, ensuring that they operate only when needed. This not only conserves energy but also enhances the overall efficiency of the truck’s electrical system 1.

Purpose and Functionality

The Magnetic Switch Bracket plays a role in the truck’s electrical system by providing a reliable method for controlling the activation and deactivation of electrical components. It is integrated with other systems such as the engine control unit (ECU) and various sensors to ensure that electrical components are powered only when necessary. This integration helps in maintaining the optimal performance of the truck while reducing unnecessary energy consumption 2.

Key Features

The primary features of the Magnetic Switch Bracket include its magnetic properties, which allow it to respond to magnetic fields for circuit control. The design of the bracket is robust, ensuring durability under the demanding conditions of commercial truck operations. It is constructed from high-quality materials that resist corrosion and wear, contributing to its longevity and reliability.

Benefits

The Magnetic Switch Bracket offers several advantages. It enhances the efficiency of the truck’s electrical system by ensuring that components are powered only when required. This results in reduced energy consumption and improved overall performance. Additionally, the bracket is designed for ease of installation, minimizing downtime during maintenance procedures. Its reliable operation contributes to the truck’s reliability, reducing the likelihood of electrical failures 3.

Installation Process

Installing the Magnetic Switch Bracket involves several steps to ensure proper functionality. Begin by identifying the correct location for the bracket within the truck’s electrical system. Secure the bracket in place using the provided mounting hardware, ensuring it is firmly attached. Connect the electrical wires to the bracket, following the manufacturer’s wiring diagram to avoid errors. Finally, test the bracket to confirm that it is operating correctly within the system.

Troubleshooting

Common issues with the Magnetic Switch Bracket may include failure to activate or deactivate circuits properly. This can often be traced to wiring issues or corrosion on the bracket’s contacts. Troubleshooting steps involve checking the wiring connections for integrity and cleaning any corrosion from the contacts. If the bracket itself is faulty, replacement may be necessary.

Maintenance Tips

Regular maintenance of the Magnetic Switch Bracket is key to ensuring its longevity and optimal performance. This includes periodic inspection of the wiring connections for signs of wear or corrosion. Cleaning the bracket and its contacts can prevent buildup that may interfere with its operation. Additionally, ensuring that the bracket is securely mounted will help prevent damage from vibrations during truck operation.

Safety Considerations

When working with the Magnetic Switch Bracket, it is important to follow safety guidelines to prevent accidents. Ensure that the truck’s electrical system is de-energized before beginning any work on the bracket. Use appropriate personal protective equipment (PPE) to protect against electrical shocks and other hazards. Adhere to all manufacturer recommendations for installation and maintenance to ensure safe operation.

Cummins Overview

Cummins is a renowned manufacturer in the commercial truck industry, known for its high-quality engines and components. With a history spanning several decades, Cummins has established a reputation for innovation, reliability, and performance. The company offers a wide range of products designed to meet the diverse needs of the commercial trucking sector, contributing to the efficiency and reliability of trucks worldwide 4.

Magnetic Switch Bracket 3068915 Compatibility with Cummins Engines

The Magnetic Switch Bracket part number 3068915, manufactured by Cummins, is designed to fit a variety of Cummins engines. This part is crucial for the proper functioning of the engine’s ignition system, ensuring that the magnetic switch operates correctly to trigger the ignition at the right time.

4B3.9 and 6B5.9 Engines

The 4B3.9 and 6B5.9 engines are part of Cummins’ B and 6B series, respectively. These engines are known for their reliability and performance in various applications, from agricultural to industrial use. The Magnetic Switch Bracket 3068915 is compatible with both these engines, ensuring that the magnetic switch is securely mounted and functions as intended.

6C8.3 and QSC8.3 CM850 (CM2850)

The 6C8.3 engine is a part of Cummins’ C series, while the QSC8.3 CM850 (CM2850) is a more advanced model in the QSC series. Both engines benefit from the precise fit of the Magnetic Switch Bracket 3068915, which is engineered to handle the specific demands of these engines, ensuring optimal performance and longevity.

B3.3 and QSL9 CM850 (CM2850)

The B3.3 engine is a smaller, more compact model within Cummins’ B series, while the QSL9 CM850 (CM2850) is a high-performance engine in the QSL series. Despite their differences, both engines are compatible with the Magnetic Switch Bracket 3068915, which is designed to fit snugly and function reliably in these applications.

L8.9, L8.9 L121, L9.3 L105, L9.5 L117

The L8.9, L8.9 L121, L9.3 L105, and L9.5 L117 engines are part of Cummins’ L series, known for their robustness and efficiency. The Magnetic Switch Bracket 3068915 is compatible with all these engines, providing a secure mounting solution that ensures the magnetic switch operates correctly, regardless of the engine model.

QSB5.9 CM850 and QSB6.7 M CM2250

The QSB5.9 CM850 and QSB6.7 M CM2250 engines are part of Cummins’ QSB series, designed for heavy-duty applications. The Magnetic Switch Bracket 3068915 is engineered to fit these engines, ensuring that the magnetic switch is securely mounted and functions as intended, even under the most demanding conditions.

Role of Part 3068915 Magnetic Switch Bracket in Engine Systems

The Part 3068915 Magnetic Switch Bracket is integral to the seamless operation of various engine systems, particularly within the realms of Electric Starting and Electrical components. This bracket is designed to securely mount the Magnetic Switch, ensuring it remains in optimal position and orientation for efficient functionality.

Integration with Engine Systems

-

Electric Starting System:

- The Magnetic Switch Bracket supports the Magnetic Switch, which is a key component in the Electric Starting System. It facilitates the engagement and disengagement of the starter motor, allowing for controlled engine start-ups.

-

Electrical System:

- Within the Electrical System, the bracket ensures the Magnetic Switch is properly aligned and connected to the necessary wiring. This is essential for the distribution of electrical power to various engine components, ensuring consistent and reliable performance.

-

Instrument Panel:

- The bracket plays a role in the mounting of the Magnetic Switch on the Instrument Panel. This placement allows for easy access and monitoring by the operator, enhancing the overall usability and safety of the engine system.

-

Engine Instrumentation:

- By securely holding the Magnetic Switch, the bracket indirectly supports the accurate reading and display of engine metrics on the Instrument Panel. This is vital for maintaining engine health and performance.

-

Accessories:

- The bracket is also involved in the integration of various accessories that rely on the Magnetic Switch for operation. This includes components like lighting systems, auxiliary power units, and other electrical accessories that enhance engine functionality and user convenience.

In summary, the Part 3068915 Magnetic Switch Bracket is a foundational component that ensures the proper installation and function of the Magnetic Switch across multiple engine systems. Its role in maintaining the structural integrity and operational efficiency of these systems cannot be overstated.

Conclusion

The Magnetic Switch Bracket (Part #3068915) by Cummins is a critical component in the electrical systems of commercial trucks. Its design and functionality contribute to the efficient and reliable operation of various electrical components, enhancing the overall performance of the truck. Proper installation, maintenance, and troubleshooting are essential to ensure the longevity and optimal performance of this Cummins part.

-

Taghavifar, H., & Mardani, A. (2017). Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer.

↩ -

Isermann, R. (2017). Combustion Engine Diagnosis. Springer Vieweg.

↩ -

Lakshminarayanan, P. A., & Aghav, Y. V. (2010). Modelling Diesel Combustion. Springer Science.

↩ -

Giles, T. (2019). Automotive Engines Diagnosis Repair and Rebuilding. Cengage Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.