3627324

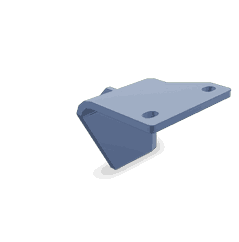

Magnetic Switch Bracket

Cummins®

AVAILABLE

1 is currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3627324 Magnetic Switch Bracket, manufactured by Cummins, is a component designed for use in commercial truck operations. Cummins, a well-established name in the industry, produces a range of parts and systems that contribute to the efficiency and reliability of heavy-duty trucks. This Cummins part plays a role in the electrical system of trucks.

Basic Concepts

Magnetic switch brackets operate on the principle of magnetism. These brackets use magnetic forces to hold electrical switches in place, ensuring they remain securely positioned within the truck’s electrical system. The fundamental principle involves the interaction between magnetic fields and metallic components, allowing for a stable and reliable mounting solution for switches. This design helps in maintaining the integrity of electrical connections and contributes to the overall functionality of the truck’s electrical system 1.

Purpose and Function

The 3627324 serves to securely mount electrical switches within a truck’s electrical system. It interacts with other components by providing a stable platform for switches, which are essential for various electrical functions within the truck. This bracket contributes to the truck’s overall performance by ensuring that electrical connections are maintained, thereby supporting the reliable operation of electrical systems.

Key Features

The 3627324 is designed with several features that enhance its functionality. It is constructed from durable materials to withstand the rigors of commercial truck operations. The bracket’s magnetic design allows for easy installation and removal of switches, facilitating maintenance and repairs. Additionally, its design ensures a secure hold on switches, reducing the risk of electrical faults due to loose connections.

Benefits

The use of the 3627324 offers several advantages. It improves the efficiency of electrical systems by ensuring secure and stable connections. The reliability of the bracket contributes to the overall dependability of the truck’s electrical system, reducing the likelihood of unexpected failures. Furthermore, the ease of installation and maintenance can lead to cost savings for fleet operators by simplifying repair processes and reducing downtime.

Installation Process

Installing the 3627324 involves several steps to ensure proper placement and functionality. First, identify the location where the bracket will be mounted. Use the appropriate tools to secure the bracket in place, ensuring it is level and firmly attached. Then, position the electrical switch within the bracket, making use of the magnetic properties to hold it securely. Finally, verify the connection by testing the electrical system to confirm that the switch is functioning correctly. Safety precautions, such as disconnecting the battery before beginning work, should be observed throughout the installation process.

Troubleshooting

Common issues with the 3627324 may include loose connections or failure of the switch to operate correctly. To troubleshoot these problems, first, check the bracket’s attachment to ensure it is secure. Inspect the switch for any signs of damage or wear that may affect its operation. If the switch appears to be functioning correctly, test the electrical connections to identify any faults. Addressing these issues promptly can help maintain the reliability of the truck’s electrical system.

Maintenance Tips

Regular maintenance of the 3627324 is important to ensure its longevity and optimal performance. Inspect the bracket and switch regularly for signs of wear or damage. Clean the bracket and switch contacts to remove any dirt or corrosion that may affect electrical connections. Following these maintenance tips can help prevent issues and ensure the continued reliable operation of the truck’s electrical system.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of heavy-duty applications. Cummins’ commitment to excellence and customer satisfaction has made it a trusted name among fleet operators and manufacturers alike 2.

Magnetic Switch Bracket 3627324 Compatibility with Cummins Engines

The Magnetic Switch Bracket part number 3627324, manufactured by Cummins, is designed to fit a variety of Cummins engines. This bracket plays a role in the engine’s operation by ensuring the magnetic switch is properly positioned and secured, which is essential for the accurate detection of engine speed and position.

QSK38 and QSK50 Series

The Magnetic Switch Bracket 3627324 is compatible with the following engines in the QSK38 and QSK50 series:

- QSK38 CM2150 MCRS

- QSK38 CM850 MCRS

- QSK50 CM2150 K107

- QSK50 CM2150 MCRS

- QSK50 CM2350 K108

These engines are known for their robust design and high performance, often used in heavy-duty applications such as marine and industrial settings. The bracket ensures that the magnetic switch is correctly aligned to provide reliable data for the engine control unit.

QSK60 Series

The bracket also fits the following engines in the QSK60 series:

- QSK60 CM500

- QSK60 CM850 MCRS

- QSK60 G CM2358 K110

- QSK60G

The QSK60 series engines are designed for high power output and efficiency, commonly used in power generation and heavy industrial applications. The Magnetic Switch Bracket 3627324 ensures the magnetic switch is securely mounted, which is critical for maintaining engine performance and reliability.

QSK78 Series

For the QSK78 series, the bracket is compatible with:

- QSK78 CM500

This engine is part of the larger QSK series, known for its durability and efficiency in demanding environments.

QSV Series

The Magnetic Switch Bracket 3627324 also fits the following engines in the QSV series:

- QSV81G

- QSV91-G4 CM558/CM700 V102

- QSV91G

- QSW/QSV82

- QSW73

These engines are typically used in a variety of applications, including marine, power generation, and industrial uses. The bracket ensures the magnetic switch is correctly positioned to support the engine’s control systems.

Other Models

Additionally, the bracket is compatible with the following engines:

- 6C8.3

- GTA38 G CMEICS G116C

- K38

- K50

These engines, while less common, are still integral to various applications where reliability and performance are paramount. The Magnetic Switch Bracket 3627324 ensures that the magnetic switch is securely mounted, providing accurate data for engine management systems.

Understanding the Integration of Part 3627324 Magnetic Switch Bracket in Engine Systems

The part 3627324 Magnetic Switch Bracket is a component in the orchestration of various engine systems, particularly those involving electric starting mechanisms. This bracket serves as a pivotal mounting point for the magnetic switch, ensuring secure and efficient operation within the engine’s electrical starting system.

Role in Electric Starting Systems

In electric starting systems, the Magnetic Switch Bracket is instrumental in facilitating the connection between the starting motor and the switch. This bracket allows for the magnetic switch to be securely positioned, enabling it to effectively engage with the starting motor when activated. The reliable mounting provided by the bracket is key to the consistent performance of the starting system, ensuring that the motor receives the necessary electrical signal to initiate engine start-up.

Interaction with Electrical Starting Accessories

The bracket’s design also plays a significant role in the integration of electrical starting accessories. By providing a stable mounting solution, it allows for the seamless incorporation of these accessories into the starting system. This is particularly important for accessories that require precise alignment and secure attachment to function correctly. The bracket ensures that these components are held in the optimal position, contributing to the overall efficiency and reliability of the starting process.

Support for Accessories and Motor Components

Beyond its primary function, the Magnetic Switch Bracket supports the integration of various accessories within the engine system. It acts as a foundational element for the attachment of electric starting accessories, ensuring that they are securely fastened and correctly aligned. This support is vital for the operation of components such as the starting motor and switch, facilitating their interaction and contributing to the smooth initiation of the engine.

Enhancing System Reliability

The secure mounting provided by the Magnetic Switch Bracket enhances the reliability of the engine’s starting system. By ensuring that the magnetic switch is firmly in place, it minimizes the risk of disconnection or misalignment, which could otherwise lead to starting failures. This reliability is essential for the consistent operation of the engine, particularly in environments where starting efficiency is paramount.

Conclusion

In summary, the 3627324 Magnetic Switch Bracket is a key component in the effective integration and operation of electric starting systems within engines. Its role in securely mounting the magnetic switch and supporting the alignment of starting accessories and motor components is fundamental to the reliable and efficient start-up of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.