This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

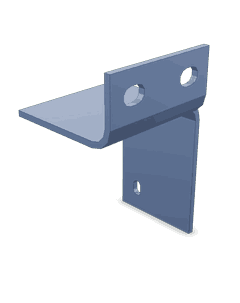

The Magnetic Switch Bracket (Part #4913801) manufactured by Cummins is a component designed to enhance the operation of heavy-duty trucks. It plays a role in the electrical system by facilitating the connection and disconnection of electrical components, contributing to the overall efficiency and reliability of the vehicle. Its significance in the automotive industry lies in its ability to improve the functionality of heavy-duty trucks, ensuring they operate smoothly under demanding conditions 1.

Basic Concepts of Magnetic Switch Brackets

A Magnetic Switch Bracket is a device that uses magnetic principles to hold and release electrical contacts. It functions by utilizing the attractive force between magnetic materials to either connect or disconnect electrical circuits. This mechanism is particularly useful in automotive systems where reliable and rapid switching of electrical components is required. The principles of magnetism are integral to the design and operation of the bracket, allowing it to perform its function efficiently and consistently 2.

Purpose and Role in Truck Operation

The purpose of the Magnetic Switch Bracket in heavy-duty trucks is to facilitate the switching of electrical circuits, which is vital for the operation of various components such as lights, sensors, and other electrical systems. It contributes to the overall functionality and efficiency of the vehicle by ensuring that electrical connections are made and broken as needed, without manual intervention. This automation enhances the reliability of the truck’s electrical system, allowing for smoother and more consistent operation 3.

Key Features

The 4913801 Magnetic Switch Bracket features a robust design that includes a durable material composition, typically involving high-strength metals to withstand the rigors of heavy-duty truck environments. Its design elements are tailored to ensure precise alignment and secure attachment of electrical contacts. Unique characteristics such as corrosion resistance and high magnetic strength enhance its performance and durability, making it suitable for long-term use in demanding applications 4.

Benefits

Using the 4913801 Magnetic Switch Bracket offers several benefits. It improves operational efficiency by ensuring reliable and rapid switching of electrical circuits. Enhanced safety features are inherent in its design, as it reduces the risk of electrical faults that could arise from poor connections. Additionally, fleet operators may experience potential cost savings due to the bracket’s durability and reduced need for frequent replacements or repairs 5.

Installation Process

Installing the Magnetic Switch Bracket involves several steps to ensure proper setup. Necessary tools include a wrench, screwdriver, and possibly a multimeter for testing electrical connections. Preparatory steps involve ensuring the electrical system is de-energized to prevent accidents. Detailed installation instructions include mounting the bracket in the designated location, securing it with the provided fasteners, and connecting the electrical contacts. Testing the connections for proper function is the final step to ensure the bracket is installed correctly 6.

Troubleshooting and Maintenance

Common issues with the Magnetic Switch Bracket may include weakened magnetic strength, corrosion, or misaligned contacts. Troubleshooting steps involve inspecting the bracket for physical damage, cleaning any corrosion, and ensuring the contacts are properly aligned. Maintenance tips to ensure longevity and optimal performance include regular inspection for signs of wear, cleaning the bracket to prevent corrosion, and testing the electrical connections periodically to ensure they remain secure and functional 7.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the automotive industry. The company’s commitment to manufacturing high-quality components is evident in its product range, which is designed to meet the demanding requirements of various applications, ensuring reliability and performance 8.

Magnetic Switch Bracket 4913801 in Cummins Engines

The Magnetic Switch Bracket 4913801, manufactured by Cummins, is a critical component in several engine models. This part is integral to the operation of the engine’s ignition system, ensuring that the magnetic switch is securely mounted and properly aligned.

M11 Mechanical Engines

In the M11 Mechanical engines, the Magnetic Switch Bracket 4913801 plays a pivotal role in maintaining the integrity of the engine’s ignition timing. This bracket is designed to withstand the high operational stresses and temperatures typical of these engines, ensuring reliable performance over extended periods.

The bracket’s precise fit and secure mounting are essential for the accurate positioning of the magnetic switch, which in turn affects the timing of the spark in the engine’s cylinders. This synchronization is crucial for the engine’s efficiency and overall performance.

The design of the bracket ensures that it can endure the vibrations and mechanical forces exerted during engine operation, maintaining its structural integrity and the proper alignment of the magnetic switch. This reliability is critical for the consistent and efficient operation of the M11 Mechanical engines 9.

Role of Part 4913801 Magnetic Switch Bracket in Engine Systems

The 4913801 Magnetic Switch Bracket is an integral component in the integration of accessories and electric starting systems within engine assemblies. This bracket facilitates the secure mounting of the magnetic switch, which is essential for the operation of the electric starting system.

When the ignition is activated, the magnetic switch, housed within the 4913801 bracket, engages the starter motor. This action is pivotal for the initial cranking of the engine, allowing for a smooth and reliable start. The bracket ensures that the switch remains in the correct position and orientation, which is necessary for consistent performance and durability of the starting system.

In addition to its role in the starting system, the 4913801 bracket also supports various accessories that may be connected to the engine. These accessories can include alternators, fuel pumps, and other electrical components that require a stable and secure mounting point. The bracket’s design allows for efficient wiring management, reducing the risk of electrical interference and ensuring that all connections remain intact during engine operation.

The integration of the 4913801 Magnetic Switch Bracket within these systems enhances the overall reliability and efficiency of the engine. By providing a robust mounting solution for the magnetic switch and supporting accessories, this component contributes to the seamless operation of the electric starting system and the proper functioning of engine-related accessories 10.

Conclusion

The 4913801 Magnetic Switch Bracket is a vital component in the operation of heavy-duty trucks and Cummins engines. Its role in facilitating the reliable and rapid switching of electrical circuits contributes to the overall efficiency and reliability of the vehicle. The robust design, key features, and benefits of this Cummins part make it an essential element in ensuring the smooth operation of heavy-duty trucks under demanding conditions. Proper installation, maintenance, and troubleshooting are crucial to maximizing the performance and longevity of the Magnetic Switch Bracket.

-

Hu, H., Smaling, R., & Baseley, S. (2014). Heavy-Duty Wheeled Vehicles. SAE International.

↩ -

Kasab, J., & Strzelec, A. (2020). Automotive Emissions Regulations and Exhaust Aftertreatment Systems. SAE International.

↩ -

Reif, K. (2014). Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg.

↩ -

Sobey, E. (2009). A Field Guide to Automotive Technology. Chicago Review Press.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5612959.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5612959.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5612959.

↩ -

Cummins Inc. (n.d.). Company Overview. Retrieved from Cummins Official Website.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5612959.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5612959.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.