This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

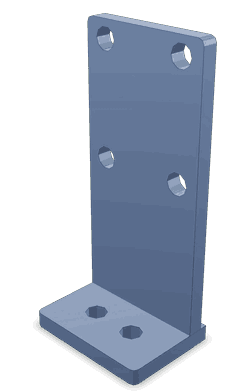

The Cummins 3175861 Shipping Bracket is a component designed for use in commercial truck operations. Its purpose is to facilitate the secure transportation of heavy-duty truck engines during shipping. This bracket plays a significant role in ensuring that engines remain stable and protected during transit, which is vital for maintaining the integrity of the engine and ensuring it arrives at its destination in optimal condition 1.

Purpose and Function

The Cummins 3175861 Shipping Bracket serves multiple functions in the operation of a truck. Primarily, it is used to secure the engine in place during shipping, reducing the risk of damage from movement or vibrations. By providing a stable mounting point, it contributes to the overall efficiency and safety of the transportation process. This bracket ensures that the engine is held firmly, minimizing the potential for shifting or impact damage 2.

Key Features

The Cummins 3175861 Shipping Bracket is characterized by several key features that enhance its performance and durability. It is constructed from high-strength materials, ensuring it can withstand the rigors of transportation. The design includes robust mounting points and secure attachment mechanisms, which provide a stable interface for the engine. Additionally, the bracket is engineered to accommodate various engine sizes and configurations, making it a versatile component for different applications 3.

Benefits

Using the Cummins 3175861 Shipping Bracket offers several benefits. It improves the stability of the engine during transport, which can lead to reduced risk of damage. Enhanced security during shipping means that engines are less likely to suffer from transit-related issues, potentially leading to cost savings for fleet operators. Additionally, the durability of the bracket ensures long-term use, providing consistent performance over multiple shipments.

Installation Process

Installing the Cummins 3175861 Shipping Bracket requires careful attention to ensure proper fitting. Begin by positioning the bracket in the designated location on the engine. Use the provided mounting hardware to secure the bracket in place, ensuring all bolts are tightened to the specified torque settings. It is important to verify that the bracket is aligned correctly and that all attachment points are secure before proceeding with shipping. Tools required may include a torque wrench and socket set.

Maintenance and Care

Regular maintenance of the Cummins 3175861 Shipping Bracket is important to ensure its longevity and optimal performance. Inspect the bracket for any signs of wear or damage before each use. Clean the bracket to remove any debris or corrosion that may have accumulated. If any components show signs of wear, consider replacing them to maintain the integrity of the bracket. Following these maintenance steps will help ensure the bracket remains in good condition for continued use.

Troubleshooting Common Issues

Common issues with the Cummins 3175861 Shipping Bracket may include loose mounting points or damage to the bracket itself. To address these problems, first, inspect the bracket for any visible signs of damage. Tighten any loose bolts or replace damaged components as necessary. If the bracket shows significant wear, it may need to be replaced to ensure the engine remains secure during transport. Regular inspections can help identify and resolve these issues promptly.

Safety Considerations

When using the Cummins 3175861 Shipping Bracket, several safety considerations should be kept in mind. Ensure that the engine is properly balanced and that the weight is distributed evenly to prevent tipping or shifting during transport. Follow the manufacturer’s guidelines for loading and securing the engine. Adhering to these safety practices will help maintain the integrity of the engine and ensure a safe transportation process.

Cummins Overview

Cummins Inc. is a well-established company with a strong reputation in the commercial truck industry. Founded in 1919, Cummins has a long history of producing high-quality engines and components. The company’s product range includes a variety of engines, filtration systems, and aftermarket parts, all designed to meet the demanding needs of commercial trucking. Cummins is known for its commitment to quality and reliability, which is reflected in the design and performance of the 3175861 Shipping Bracket.

Cummins Engine Compatibility with Shipping Bracket Part 3175861

The Cummins Shipping Bracket part number 3175861 is designed to fit a variety of Cummins engines, ensuring secure mounting and transportation. This bracket is compatible with several engine models, including:

-

QSK38 Series:

- QSK38 CM2150 MCRS

- QSK38 CM850 MCRS

-

QSK45 Series:

- QSK45 CM500

-

QSK50 Series:

- QSK50 CM2150 K107

- QSK50 CM2150 MCRS

- QSK50 CM2350 K108

-

QSK60 Series:

- QSK60 CM500

- QSK60G

-

QSK78 Series:

- QSK78 CM500

This bracket is engineered to provide a robust and reliable mounting solution, ensuring that the engines remain stable during transit and installation. Its design accommodates the specific mounting points and structural requirements of the listed engines, facilitating seamless integration and operation.

Role of Part 3175861 Shipping Bracket in Engine Systems

The Part 3175861 Shipping Bracket is an essential component in the secure arrangement and transportation of engine systems. Its primary function is to provide a stable and reliable mounting solution during the shipping process, ensuring that the engine components remain intact and undamaged.

Integration with Base Parts

When integrating with base parts, the Shipping Bracket plays a significant role in maintaining the structural integrity of the engine during transit. It is designed to interface seamlessly with the base part, offering a robust connection point that distributes the weight and stress evenly across the engine system. This helps prevent any potential damage that could occur from shifting or excessive movement during shipping.

Contribution to Overall Arrangement

In the overall arrangement of the engine components, the Shipping Bracket ensures that all parts are securely fastened and organized. This is particularly important for complex engine systems where multiple components need to be transported together. The bracket helps in maintaining the correct alignment and spacing between parts, which is vital for the proper functioning of the engine once it reaches its destination.

Enhancing Shipping Safety

During the shipping process, the Shipping Bracket acts as a protective measure, safeguarding the engine components from external impacts and vibrations. It is engineered to absorb shocks and reduce the risk of parts becoming dislodged or damaged. This is especially important for high-value engine systems where even minor damage can lead to significant repair costs or delays in installation.

Supporting Base Part Stability

The stability of the base part is paramount in ensuring the engine system’s safe transportation. The Shipping Bracket provides additional support to the base part, reinforcing its structure and preventing any potential warping or deformation. This support is crucial for maintaining the engine’s performance and longevity, as a stable base part ensures that all connected components operate within their designed parameters.

Facilitating Easy Handling

One of the practical benefits of the Shipping Bracket is its role in facilitating easy handling of the engine system. By securely attaching to the base part and other components, it allows for safer and more efficient loading and unloading processes. This reduces the risk of injury to personnel and minimizes the likelihood of accidental damage to the engine during transit.

Ensuring Component Alignment

Proper alignment of engine components is essential for their optimal performance. The Shipping Bracket helps in maintaining this alignment by keeping all parts in their designated positions. This is particularly important for precision-engineered components that require exact placement to function correctly. The bracket ensures that once the engine is installed, it can be quickly and accurately aligned, reducing setup time and enhancing overall efficiency.

Conclusion

The Cummins 3175861 Shipping Bracket is a critical component in the secure transportation of heavy-duty truck engines. Its robust design, compatibility with various engine models, and the benefits it offers in terms of stability, safety, and ease of handling make it an indispensable part of the shipping process. Regular maintenance and proper installation are essential to ensure the bracket’s longevity and effectiveness, ultimately contributing to the overall efficiency and reliability of engine transportation in commercial trucking operations.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.