This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

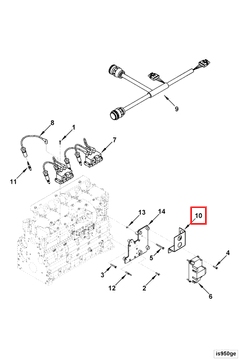

The Cummins 3938921 Wiring Retainer Bracket is designed to enhance the electrical system’s integrity in heavy-duty trucks. It secures and organizes wiring harnesses, which are essential for the truck’s operation. By maintaining the wiring in an orderly and protected manner, the bracket contributes to the overall efficiency and reliability of the vehicle’s electrical system 1.

Purpose and Function

The Wiring Retainer Bracket anchors and arranges the wiring harnesses within the truck’s engine compartment. This organization prevents wires from becoming tangled or damaged, which could lead to electrical faults. By securing the wires, the bracket helps maintain a clean and efficient electrical pathway, ensuring that the truck’s systems operate smoothly and without interruption 2.

Key Features

The design of the Cummins 3938921 incorporates durable materials that can withstand the harsh conditions of a heavy-duty truck environment. It is constructed to offer robust mounting options, allowing for flexible installation that can accommodate various truck configurations. The bracket’s unique attributes, such as its corrosion-resistant coating and precise engineering, enhance its performance and longevity.

Benefits

Utilizing the Wiring Retainer Bracket offers several advantages. It improves wire management by keeping the harnesses in place, which reduces the likelihood of wear and tear on the wires. This, in turn, lowers the risk of electrical faults that could compromise the truck’s operation. Additionally, by ensuring that the wiring is secure and well-organized, the bracket contributes to the safety and reliability of the truck’s electrical system.

Installation and Compatibility

Proper installation of the Wiring Retainer Bracket is crucial for its effective function. It should be mounted according to the manufacturer’s guidelines to ensure it is securely fastened and correctly positioned. Compatibility with specific truck models and engine types is important to guarantee that the bracket fits and operates as intended within the truck’s electrical system.

Maintenance and Troubleshooting

To maintain the Wiring Retainer Bracket and ensure its optimal performance, regular inspections should be conducted to check for any signs of wear or damage. If issues arise, such as loose mounting or damaged brackets, they should be addressed promptly to prevent further complications. Troubleshooting may involve tightening fasteners, replacing worn components, or adjusting the bracket’s position to resolve any problems.

Safety Considerations

When installing or working with the Wiring Retainer Bracket, it is important to follow safety practices to avoid electrical hazards. This includes ensuring that the truck’s battery is disconnected before beginning any work on the electrical system. Personal protective equipment should be worn, and all tools and equipment should be insulated to prevent accidental contact with live wires.

Cummins Overview

Cummins Inc. is a prominent manufacturer of diesel engines with a rich history of innovation and quality in the automotive industry. The company’s components, including the Wiring Retainer Bracket, are designed to meet the demanding requirements of heavy-duty applications. Cummins’ commitment to excellence ensures that their products contribute to the reliability and performance of the vehicles they are installed in 3.

Role of Part 3938921 Wiring Retainer Bracket in Engine Systems

The 3938921 Wiring Retainer Bracket is an essential component in maintaining the integrity and organization of various wiring systems within engine assemblies. Its primary function is to secure and manage the wiring harnesses, ensuring they remain in place and protected from potential damage during engine operation.

Integration with Harness

The Wiring Retainer Bracket is strategically positioned along the wiring harness to prevent chafing and abrasion. By clamping the harness in place, it reduces the risk of wires coming into contact with moving parts or sharp edges within the engine bay. This not only preserves the functionality of the harness but also enhances the overall reliability of the electrical system.

Electronic Control Module (ECM) Wiring

In systems where the Electronic Control Module (ECM) wiring is involved, the 3938921 Bracket plays a significant role. It ensures that the sensitive ECM wiring remains organized and protected. This is particularly important in modern engines where the ECM controls various functions such as fuel injection, ignition timing, and emissions control. Proper management of ECM wiring is vital for consistent and accurate data transmission, which directly impacts engine performance and efficiency.

System-Wide Application

Across different engine systems, the Wiring Retainer Bracket contributes to the overall tidiness and safety of the wiring layout. Whether it’s in gasoline, diesel, or hybrid engines, the bracket helps in routing wires away from heat sources and mechanical components. This is essential in preventing thermal damage and ensuring that the wires do not interfere with the operation of other engine parts.

Ignition System

In ignition systems, the 3938921 Bracket secures ignition wiring, which is critical for spark plug operation. By keeping the ignition wires in their designated paths, the bracket helps maintain consistent spark delivery to the cylinders. This is fundamental for reliable engine starting and smooth operation, especially under varying load conditions.

Conclusion

The 3938921 Wiring Retainer Bracket is a fundamental component in the maintenance and protection of engine wiring systems, contributing to the durability and performance of the engine as a whole. Its role in securing and organizing wiring harnesses is crucial for the efficient and reliable operation of heavy-duty trucks.

-

Singh, D. K. (2024). Dictionary of Mechanical Engineering. Springer Nature.

↩ -

ElSayed, M. (2017). Fundamentals of Integrated Vehicle Realization. SAE International.

↩ -

Cummins Inc. (n.d.). Company Overview. Retrieved from Cummins Official Website.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.