This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

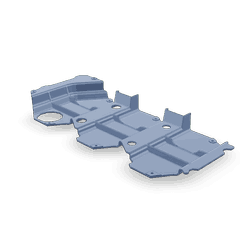

The Cummins 2830882 Breather Baffle is a component designed for use in heavy-duty trucks. It serves a specific function within the vehicle’s fuel system, contributing to the overall efficiency and reliability of the truck. Understanding its purpose and operation is key to maintaining the vehicle’s performance and longevity.

Basic Concepts

A breather baffle is a device installed within the fuel tank of a vehicle. Its primary role is to manage the airflow within the tank, ensuring that the fuel system operates under optimal conditions. By controlling the pressure inside the tank, the breather baffle helps maintain the integrity of the fuel system, preventing issues such as fuel vaporization and contamination 1.

Purpose of the 2830882 Breather Baffle

The Cummins 2830882 Breather Baffle plays a role in the truck’s fuel system by managing fuel tank pressure and preventing fuel contamination. As the vehicle operates, the fuel within the tank expands and contracts due to temperature changes. The breather baffle allows air to enter and exit the tank as needed, stabilizing the pressure inside. This function is vital for preventing fuel from vaporizing excessively, which can lead to engine performance issues. Additionally, by filtering the air that enters the tank, the breather baffle helps keep contaminants out of the fuel, ensuring cleaner combustion and reduced wear on engine components 2.

Key Features

The Cummins 2830882 Breather Baffle is characterized by its robust design and the materials used in its construction. It is engineered to withstand the harsh conditions found within a heavy-duty truck’s fuel system. The baffle is made from durable materials that resist corrosion and wear, ensuring long-term reliability. Its design includes features that enhance its performance, such as a filtration system to trap contaminants and a structure that efficiently manages airflow.

Benefits

Incorporating the Cummins 2830882 Breather Baffle into a truck’s fuel system offers several advantages. It contributes to improved fuel system efficiency by maintaining optimal pressure levels within the fuel tank. This stability ensures that the fuel delivery system operates smoothly, leading to consistent engine performance. Additionally, by preventing fuel contamination, the breather baffle helps protect the engine from damage caused by impurities in the fuel, enhancing the truck’s overall performance and reliability 3.

Installation Process

Installing the Cummins 2830882 Breather Baffle requires careful attention to ensure a secure fit and proper function. The process involves accessing the fuel tank, positioning the baffle correctly within the tank, and securing it in place. Tools and equipment necessary for installation may include wrenches, a fuel system cleaner, and possibly a fuel tank seal kit, depending on the specific requirements of the truck model. Following manufacturer guidelines for installation is crucial to ensure the breather baffle functions as intended.

Troubleshooting and Maintenance

Common issues with the breather baffle may include blockages in the airflow path or damage to the filtration system. Regular inspection and cleaning can help prevent these problems. Diagnostic procedures for identifying issues may involve checking for signs of fuel contamination, unusual engine performance, or pressure irregularities within the fuel tank. Maintenance tips include periodic cleaning of the baffle and ensuring that it remains securely installed. Addressing issues promptly can help maintain the efficiency and reliability of the truck’s fuel system.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is committed to innovation, quality, and customer satisfaction. The company’s product range includes engines and components for on-highway, off-highway, and stationary applications, demonstrating its versatility and expertise in the automotive industry. Cummins’ commitment to advancing technology and improving product performance underscores its position as a leader in the field.

Compatibility of Cummins Breather Baffle Part 2830882

The Cummins Breather Baffle part number 2830882 is designed to manage the airflow within the engine’s crankcase, ensuring optimal performance and longevity. This part is compatible with a variety of Cummins engine models, each of which has specific configurations and requirements.

ISB Series Engines

- ISB CM2150

- ISB/ISD4.5 CM2150 B119

- ISB/ISD6.7 CM2150 SN

- ISB5.9 CM2880 B110

- ISB6.7 CM2250

- ISBE CM2150

- ISBE CM800

- ISBE4 CM850

The ISB series engines, including the CM2150, CM2250, and CM2880 models, benefit from the breather baffle’s ability to prevent oil vapor from re-entering the intake manifold, thus maintaining clean airflow and reducing engine wear.

QSB Series Engines

- QSB4.5 CM2250 EC

- QSB4.5 CM850 (CM2850)

- QSB5.9 CM2880 B115

- QSB6.7 CM2250

- QSB6.7 CM850 (CM2850)

- QSB7 CM2880 B117

The QSB series engines, which include the CM2250, CM2880, and CM850 models, also rely on the breather baffle to manage crankcase pressure and prevent oil contamination. The breather baffle’s design ensures that these engines operate efficiently, even under demanding conditions.

Grouping by Engine Series

ISB Series Group

The ISB series engines, with their various configurations, are designed for applications requiring high performance and reliability. The breather baffle part 2830882 is engineered to fit seamlessly into these engines, providing the necessary air management to maintain optimal engine health.

QSB Series Group

The QSB series engines are built for durability and efficiency, often used in heavy-duty applications. The breather baffle part 2830882 is compatible with these engines, ensuring that they can handle the rigors of demanding environments while maintaining peak performance.

Role of Part 2830882 Breather Baffle in Engine Systems

The part 2830882 Breather Baffle is a component in the arrangement of various engine systems, particularly in the management of crankcase ventilation. This component is strategically positioned within the valve cover to optimize the functionality of the engine’s ventilation system.

Integration with Valve Cover

The breather baffle works in conjunction with the valve cover to regulate the flow of gases within the crankcase. By directing the flow of these gases, the baffle ensures that the valve cover maintains an optimal pressure level. This is achieved by allowing fresh air to enter the crankcase while venting out contaminated air, thus preventing the buildup of pressure that could lead to oil leaks or other mechanical issues.

Function within the Valve Cover

Inside the valve cover, the breather baffle plays a significant role in separating the clean air intake from the contaminated air exhaust. This separation is vital for maintaining the integrity of the engine’s lubrication system. The baffle ensures that the valves within the cover operate in a clean environment, free from contaminants that could otherwise accelerate wear and reduce efficiency.

Overall System Benefits

The effective placement and function of the breather baffle within the valve cover contribute to the overall health and performance of the engine. By ensuring proper ventilation and maintaining a clean operating environment for the valves, the baffle helps in prolonging the lifespan of the engine components and enhancing the engine’s reliability and performance.

Conclusion

The Cummins 2830882 Breather Baffle is a critical component for maintaining the efficiency and reliability of heavy-duty truck engines. By managing airflow within the fuel tank and crankcase, it ensures optimal pressure levels and prevents contamination, contributing to the overall performance and longevity of the engine.

-

Caines, Arthur J, Roger F Haycock, and John E Hillier. Automotive Lubricants Reference Book. SAE International, 2004.

↩ -

Martyr, A.J. Engine Testing: Theory and Practice: Third Edition. SAE International, 2007.

↩ -

Zhao, Hua. Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press, 2010.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.