This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

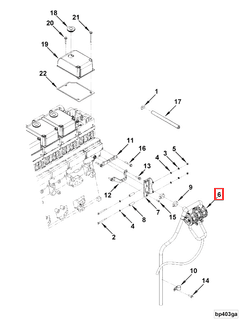

The BREATHER, CRANKCASE (Part #2863341) manufactured by Cummins is a component designed to facilitate the ventilation of the crankcase in heavy-duty trucks. It plays a role in the crankcase ventilation system by allowing the release of blow-by gases and maintaining clean crankcase air, which is vital for the engine’s operation 1.

Basic Concepts of Crankcase Ventilation

The crankcase ventilation system is designed to manage the gases that escape past the piston rings into the crankcase, known as blow-by gases. These gases contain combustion byproducts and can contaminate the engine oil if not properly ventilated. The system’s role is to expel these gases while allowing fresh air to enter the crankcase, thus maintaining oil cleanliness and engine efficiency. The breather is a key component in this system, facilitating the flow of gases and air 2.

Function and Operation of the BREATHER, CRANKCASE

The BREATHER, CRANKCASE operates by allowing the passage of gases and air through a series of filters and passages. As the engine runs, blow-by gases are directed through the breather, where they are filtered to remove contaminants before being released into the atmosphere. Simultaneously, the breather allows fresh air to enter the crankcase, ensuring that the internal environment remains clean and conducive to optimal engine performance 3.

Purpose of the BREATHER, CRANKCASE in Truck Operation

In the operation of a heavy-duty truck, the BREATHER, CRANKCASE contributes to engine efficiency, longevity, and performance by ensuring that the crankcase remains free of contaminants. By maintaining clean crankcase air, the breather helps to preserve the quality of the engine oil, which is crucial for lubrication and cooling. This, in turn, supports the engine’s overall efficiency and durability 4.

Key Features of the Cummins BREATHER, CRANKCASE

The Cummins BREATHER, CRANKCASE is characterized by its robust design and construction. It is made from high-quality materials that ensure durability and reliability under the demanding conditions of heavy-duty truck operation. The breather incorporates advanced filtration technology to effectively remove contaminants from the blow-by gases, enhancing its functionality within the crankcase ventilation system.

Benefits of Using the Cummins BREATHER, CRANKCASE

Incorporating the Cummins BREATHER, CRANKCASE into a truck’s engine system offers several advantages. These include improved engine performance due to cleaner crankcase air, reduced maintenance needs as a result of effective filtration, and enhanced durability of the engine components thanks to the breather’s role in maintaining oil quality.

Troubleshooting and Maintenance Suggestions

Common issues related to the BREATHER, CRANKCASE may include clogging of the filter elements or damage to the housing. Regular maintenance practices, such as inspection and cleaning of the breather, can help ensure optimal performance and longevity. It is advisable to follow the manufacturer’s guidelines for maintenance intervals and procedures to keep the breather in top condition.

Installation and Replacement Procedures

Proper installation and replacement of the BREATHER, CRANKCASE involve several steps to ensure correct fitting and function within the engine system. It is important to follow the manufacturer’s instructions carefully, paying attention to the orientation of the breather and the securement of all connections. Best practices include verifying the compatibility of the replacement part with the engine model and ensuring that all seals and gaskets are in good condition.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the automotive and heavy-duty truck industry. The company’s commitment to excellence is reflected in its wide range of products, including the BREATHER, CRANKCASE, which is designed to meet the rigorous demands of heavy-duty applications.

Role of Part 2863341 BREATHER,CRANKCASE in Engine Systems

In the intricate arrangement of an engine system, the BREATHER, CRANKCASE assumes a significant role by facilitating the efficient management of gases within the crankcase. This component is integral to maintaining the engine’s performance and longevity.

Integration with Crankcase Components

The BREATHER, CRANKCASE is designed to interface directly with the crankcase, a vital part of the engine that houses the crankshaft. Its primary function is to allow the escape of gases that accumulate within the crankcase during engine operation. These gases, which include unburned fuel, combustion byproducts, and moisture, can build up pressure if not properly vented. The breather ensures that this pressure is relieved in a controlled manner, preventing damage to the crankcase and associated components.

Interaction with the Crankcase Breather System

Part 2863341 is a key element in the crankcase breather system, working in conjunction with other breather components to maintain a balanced internal environment. It is typically connected to a network of hoses and valves that direct the flow of gases either back into the intake system for re-burning or to an external vent. This recirculation not only helps in reducing emissions but also ensures that the engine operates within optimal parameters.

Contribution to Engine Base and Overall System

At the engine base, the BREATHER, CRANKCASE contributes to the stability and efficiency of the entire system. By managing crankcase pressure, it aids in reducing oil consumption and preventing oil leaks, which are common issues when crankcase pressure is not properly controlled. Furthermore, it supports the engine’s lubrication system by ensuring that oil does not become contaminated with combustion gases, which can lead to decreased lubrication efficiency and increased wear on moving parts.

Enhancing Component Longevity

The effective operation of the BREATHER, CRANKCASE is essential for the longevity of various engine components. By preventing the buildup of harmful gases, it protects sensitive parts such as piston rings, bearings, and the crankshaft itself from premature wear. This, in turn, contributes to the overall reliability and performance of the engine.

Conclusion

In summary, part 2863341 BREATHER,CRANKCASE plays a pivotal role in the engine system by ensuring proper ventilation of the crankcase, contributing to the efficient operation and durability of the engine components.

-

Modelling Diesel Combustion, P A Lakshminarayanan and Yogesh V Aghav, Springer Science, 2010

↩ -

Automotive Engines Diagnosis Repair and Rebuilding, Tim Giles, Cengage Learning, 2019

↩ -

Gas Turbine Engineering Handbook 4th Edition, Meherwan P Boyce, Butterworth-Heinemann, 2011

↩ -

Fault Code Troubleshooting Manual, ISG12 CM2880 G107, Bulletin Number 4332693

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.