This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Crankcase Breather 3688716 is a component manufactured by Cummins, a well-established name in the automotive industry, particularly known for its diesel engines. This breather plays a role in the operation of commercial trucks by ensuring the engine’s crankcase maintains optimal pressure and cleanliness, which is vital for the engine’s performance and longevity.

Basic Concepts of Crankcase Breather

A crankcase breather is a device designed to release pressure that builds up inside the engine’s crankcase. As the engine operates, it produces gases and vapors that need to be expelled to prevent pressure buildup, which could lead to oil leaks and other engine issues. The breather allows these gases to escape while preventing external contaminants from entering the crankcase, thus maintaining engine health 1.

Purpose of the 3688716 Crankcase Breather

The 3688716 Crankcase Breather is specifically engineered to manage the pressure within the crankcase of a truck’s engine. It facilitates the expulsion of contaminants and moisture that accumulate during engine operation. By doing so, it helps in preserving the engine’s internal components, ensuring smooth operation and reducing the risk of damage caused by pressure buildup or contamination 2.

Key Features

The 3688716 Crankcase Breather is characterized by its robust design and the use of high-quality materials, ensuring durability and reliable performance. Its design incorporates features that enhance its efficiency in expelling contaminants while preventing the ingress of external particles. The breather’s construction is tailored to withstand the harsh conditions typical of commercial truck operations, ensuring long-term reliability 3.

Benefits of Using the 3688716 Crankcase Breather

Incorporating the 3688716 Crankcase Breather into truck engines offers several advantages. It contributes to improved engine performance by maintaining optimal crankcase pressure and cleanliness. This, in turn, can lead to enhanced engine longevity and reduced maintenance requirements. The breather’s efficient design also aids in easier maintenance, allowing for straightforward inspection and servicing 4.

Installation and Compatibility

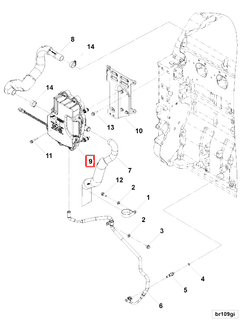

Proper installation of the 3688716 Crankcase Breather is crucial for its effective operation. It is designed to be compatible with specific Cummins engines and truck models, ensuring a seamless integration into the engine system. Following the manufacturer’s guidelines for installation is recommended to ensure compatibility and optimal performance.

Maintenance and Troubleshooting

Regular maintenance of the 3688716 Crankcase Breather is important to ensure its continued efficient operation. This includes periodic inspection for signs of wear or damage and cleaning as necessary. Troubleshooting common issues, such as reduced efficiency or contamination, can often be addressed by following the manufacturer’s maintenance recommendations and ensuring the breather is correctly installed and functioning as intended.

Environmental Impact

The 3688716 Crankcase Breather contributes to reducing emissions and enhancing fuel efficiency by maintaining optimal engine conditions. By ensuring the crankcase is free from contaminants and operates under the correct pressure, the breather helps the engine run more efficiently, which can lead to lower emissions and improved fuel economy, aligning with environmental standards and regulations.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a history of innovation and a commitment to quality, Cummins has established itself as a trusted name in the automotive industry, providing reliable and efficient power solutions for various applications, including commercial trucks.

Compatibility with Cummins Engines

The Crankcase Breather part 3688716, manufactured by Cummins, is designed to manage the ventilation and pressure within the engine’s crankcase. This part ensures that the engine operates efficiently by allowing the escape of gases and preventing the buildup of harmful pressure.

Compatibility with ISX15 Engines

The ISX15 CM2250 and ISX15 CM2350 X101 engines are equipped with the Crankcase Breather part 3688716. This part is integral to maintaining the integrity of the crankcase by facilitating the controlled release of gases, which helps in reducing the risk of engine damage due to pressure buildup.

Compatibility with QSX15 Engines

The QSX15 CM2250 and QSX15 CM2250 ECF engines also utilize the Crankcase Breather part 3688716. This part ensures that the crankcase remains ventilated, which is crucial for the longevity and performance of these engines. The breather helps in maintaining optimal pressure levels, thereby preventing potential issues related to crankcase pressure.

Compatibility with X15 CM2350 X116B

The X15 CM2350 X116B engine is another model that incorporates the Crankcase Breather part 3688716. This part is essential for managing the crankcase ventilation in this engine, ensuring that the engine operates smoothly and efficiently. The breather’s role in this engine is to prevent the accumulation of gases that could otherwise lead to pressure-related problems.

Compatibility with QSX15 CM2350 X105

The QSX15 CM2350 X105 engine is designed to work seamlessly with the Crankcase Breather part 3688716. This part is crucial for the proper functioning of the engine’s crankcase ventilation system, ensuring that the engine maintains optimal pressure levels and operates without issues related to gas buildup.

Role of Part 3688716 Crankcase Breather in Engine Systems

In the context of engine systems, the part 3688716 Crankcase Breather is integral to maintaining the health and efficiency of the engine. This component is designed to manage the pressure within the crankcase by allowing gases to escape, which helps in preventing the buildup of harmful contaminants.

When the engine operates, it produces blow-by gases—a mixture of air, fuel, and combustion byproducts—that escape past the piston rings into the crankcase. The Crankcase Breather, part 3688716, provides a controlled pathway for these gases to be vented. This process is essential for several reasons:

-

Pressure Regulation: By allowing gases to escape, the breather helps maintain a stable pressure within the crankcase. This stability is important for the proper functioning of seals and gaskets, which rely on consistent pressure to maintain their integrity.

-

Contaminant Removal: The breather system often includes a filter that captures particulate matter and moisture from the expelled gases. This filtration is vital for preventing these contaminants from circulating within the engine, which could lead to increased wear and reduced performance.

-

Lubrication System Protection: The crankcase breather works in conjunction with the Positive Crankcase Ventilation (PCV) system to ensure that the lubrication system remains clean. By venting gases away from the crankcase, it reduces the likelihood of sludge formation, which can impair the effectiveness of the oil.

-

Emission Control: Modern engines are equipped with systems that recirculate crankcase gases back into the intake manifold, where they are burned again in the combustion chamber. The Crankcase Breather, part 3688716, plays a role in this process by ensuring that gases are properly directed and filtered before re-entry.

Conclusion

In summary, the part 3688716 Crankcase Breather is a component that supports multiple aspects of engine operation, from pressure management and contaminant removal to lubrication system protection and emission control. Its effective functioning is essential for the overall performance and longevity of the engine.

-

Martyr, A.J. (2007). Engine Testing: Theory and Practice: Third Edition. SAE International.

↩ -

Lakshminarayanan, P. A., & Agarwal, A. K. (2019). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer.

↩ -

Reif, K. (Ed.). (2015). Gasoline Engine Management Systems and Components. Springer Vieweg.

↩ -

Bennett, S., & Norman, I. A. (2011). Heavy Duty Truck Systems Fifth Edition. Delmar Cengage Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.