This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The BREATHER, CRANKCASE (Part #4897553) by Cummins is a vital component designed for commercial trucks, aimed at managing the pressure within the engine’s crankcase and expelling contaminants that could otherwise impair engine performance. This part is crucial for maintaining the health and efficiency of the engine system in heavy-duty applications.

Basic Concepts of Crankcase Breathers

A crankcase breather is a device that regulates the pressure inside the crankcase by allowing air to enter and exit. This function is essential to prevent pressure buildup due to piston movement and blow-by gases, which could lead to leaks or damage. Additionally, it aids in removing moisture and contaminants, contributing to the engine’s overall health 1.

Role and Function of the Breather, Crankcase

The BREATHER, CRANKCASE by Cummins is integral to the operation of a truck by managing the internal pressure of the crankcase. It releases excess pressure in a controlled manner, preventing damage to seals and gaskets. Furthermore, it expels contaminants such as moisture and unburnt fuel, ensuring that the engine oil remains clean and effective 2.

Key Features of the Cummins Breather, Crankcase

This Cummins part is constructed with durability and efficiency in mind. It is made from high-quality materials capable of withstanding the harsh conditions of a commercial truck engine. The design includes advanced filtration capabilities to ensure that only clean air enters the crankcase, while contaminants are effectively expelled. Unique design elements may include a multi-stage filtration system and a robust housing that can endure high temperatures and pressures 3.

Benefits of Using the Cummins Breather, Crankcase

Utilizing this part offers several advantages. It contributes to improved engine performance by maintaining optimal crankcase pressure and clean oil. This can lead to enhanced engine longevity and reliability, as the risk of contamination-related issues is reduced. Additionally, the efficient design of the breather can help to minimize oil consumption and reduce the frequency of oil changes, offering cost savings over time 4.

Installation and Integration

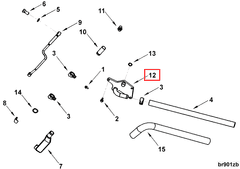

Proper installation of the BREATHER, CRANKCASE is vital for its effective operation. It should be integrated into the truck’s engine system according to the manufacturer’s guidelines. This may involve ensuring a secure fit and proper alignment with other components. Specific requirements may include the use of gaskets or seals to prevent leaks and the correct routing of hoses or tubes connected to the breather.

Maintenance and Troubleshooting

Regular maintenance of the BREATHER, CRANKCASE is recommended to ensure optimal performance. This may include periodic inspection for signs of wear or damage, cleaning or replacing filters as necessary, and checking for proper operation. Troubleshooting common issues may involve addressing leaks, ensuring the breather is not obstructed, and verifying that it is functioning within the specified parameters.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company offers a wide range of products designed to meet the demanding requirements of heavy-duty applications, with a commitment to customer satisfaction and technological advancement.

Conclusion

The BREATHER, CRANKCASE (Part #4897553) by Cummins is a critical component in maintaining the health and efficiency of engine systems. Its role in pressure regulation, contamination control, and lubrication system efficiency is indispensable for optimal engine performance and longevity.

-

Pulkrabek, W. W. (2014). Engineering Fundamentals of the Internal Combustion Engine. Pearson Education.

↩ -

Stiesch, G. (2003). Modeling Engine Spray and Combustion Processes. Springer Verlag.

↩ -

Wharton, A. J. (1991). Diesel Engines. Butterworth-Heinemann Ltd.

↩ -

Cummins Inc. (n.d.). Troubleshooting and Repair Manual for QSK60G Generator CM700. Bulletin Number 4021396.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.