This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

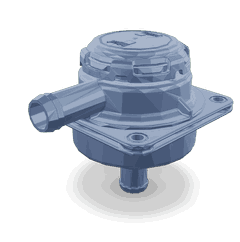

This article provides an in-depth overview of the BREATHER, CRANKCASE (Part #5267075) manufactured by Cummins. It covers the basic concepts, functionality, purpose, key features, benefits, and maintenance suggestions for this component. The information is intended for engineers, mechanics, truck drivers, and fleet operators.

Basic Concepts and Functionality

The crankcase breather is a critical component designed to manage pressure within the crankcase of an engine. It allows for the release of gases and vapors that accumulate during engine operation. The breather ensures that the crankcase maintains a stable pressure, which is important for the proper functioning of the engine 1.

Purpose of the 5267075 BREATHER, CRANKCASE

The 5267075 BREATHER, CRANKCASE plays a vital role in the engine’s ventilation system by allowing the release of blow-by gases that escape past the piston rings. This helps in maintaining optimal pressure within the crankcase, which can affect engine performance and longevity. It also helps prevent the buildup of contaminants that could lead to engine wear 2.

Key Features

- Designed for use in Cummins engines

- Constructed from durable materials to withstand high temperatures and pressures

- Engineered to efficiently vent crankcase gases

- Incorporates a filtration system to trap contaminants

- Compatible with specific Cummins engine models

Benefits

- Helps maintain stable crankcase pressure

- Reduces the risk of engine wear by venting blow-by gases

- Enhances engine performance and longevity

- Minimizes the buildup of contaminants within the crankcase

- Contributes to overall engine efficiency

Troubleshooting and Maintenance

Regular inspection of the crankcase breather is recommended to ensure it is functioning correctly. Signs of a malfunctioning breather may include oil leaks, increased engine noise, or contaminated oil. Maintenance procedures may involve cleaning or replacing the breather if signs of wear or damage are detected. It is also important to ensure that the breather is properly installed and sealed to prevent air leaks 3.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. The company is known for its commitment to innovation, quality, and customer satisfaction. Cummins engines are used in a variety of applications, including commercial trucks, where reliability and performance are paramount 4.

Compatibility of 5267075 BREATHER, CRANKCASE

This Cummins part is designed to fit a variety of Cummins engines, ensuring optimal performance and reliability. This part is essential for managing the crankcase ventilation and pressure, which is crucial for the engine’s overall health and efficiency.

Compatible Engines

F3.8 Series:

- F3.8 CM2350 F120B

- F3.8 CM2350 F128C

- F3.8 CM2620 F137B

- QSF3.8 CM2350 F107

F4.5 Series:

- F4.5 CM2620 F139B

ISB4.5 Series:

- ISB4.5 CM2350 B104

ISF3.8 Series:

- ISF3.8 CM2220 AN

- ISF3.8 CM2350 F109

The 5267075 BREATHER, CRANKCASE is engineered to provide a secure fit and efficient operation across these engines, ensuring that the crankcase ventilation system functions as intended. This part is a critical component for maintaining the integrity of the engine’s crankcase and preventing issues related to pressure build-up and contamination.

Role of 5267075 BREATHER, CRANKCASE in Engine Systems

The 5267075 BREATHER, CRANKCASE is an essential component in maintaining the health and efficiency of engine systems. Its primary function is to manage the pressure within the crankcase by allowing air and gases to escape, thereby preventing the buildup of harmful contaminants and pressure that could otherwise lead to engine damage.

Interaction with Engine Components

-

Crankcase Ventilation System: The 5267075 BREATHER, CRANKCASE is integral to the crankcase ventilation system. It works in conjunction with the Positive Crankcase Ventilation (PCV) valve to ensure that blow-by gases—which consist of unburned fuel, combustion byproducts, and moisture—are effectively routed back into the intake manifold. This process not only reduces emissions but also helps in maintaining optimal engine performance 5.

-

Oil Management: By regulating the pressure within the crankcase, the 5267075 BREATHER, CRANKCASE assists in preventing oil leaks. Excessive pressure can force oil past seals and gaskets, leading to leaks. Proper ventilation ensures that the crankcase maintains a stable environment, safeguarding the integrity of oil seals and prolonging the life of the engine’s lubrication system.

-

Fuel Efficiency and Emissions Control: Efficient crankcase ventilation directly impacts fuel efficiency and emissions. The 5267075 BREATHER, CRANKCASE, by ensuring that blow-by gases are properly managed and recirculated, helps in reducing unburned hydrocarbons released into the atmosphere. This not only complies with environmental regulations but also enhances the overall efficiency of the engine.

-

Engine Longevity: Consistent and proper ventilation of the crankcase contributes to the longevity of the engine. By preventing the accumulation of sludge and contaminants, the 5267075 BREATHER, CRANKCASE helps in maintaining clean oil, which is vital for the lubrication of moving parts. This reduces wear and tear, leading to a more durable engine.

Conclusion

In summary, the 5267075 BREATHER, CRANKCASE plays a significant role in the efficient operation and maintenance of engine systems by ensuring proper ventilation, managing oil integrity, and contributing to reduced emissions and enhanced fuel efficiency. Regular maintenance and inspection of this part are crucial for the longevity and performance of Cummins engines.

-

Wright, G. (2015). Fundamentals of Medium-Heavy Duty Diesel Engines. Jones & Bartlett Learning.

↩ -

Smil, V. (2010). The History and Impact of Diesel Engines and Gas Turbines. The MIT Press.

↩ -

Stiesch, G. (2003). Modeling Engine Spray and Combustion Processes. Springer Verlag.

↩ -

Boyce, M. P. (2011). Gas Turbine Engineering Handbook 4th Edition. Butterworth-Heinemann.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for QSK23 CM2250 K109. Bulletin Number 4367359.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.