This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Bushing Sleeve 3942013, manufactured by Cummins, is a component designed to enhance the operational efficiency and durability of commercial trucks. Cummins, a well-established name in the commercial truck industry, produces a range of parts and systems that contribute to the reliability and performance of heavy-duty vehicles. This Cummins part plays a significant role in maintaining the mechanical integrity of trucks.

Basic Concepts of Bushing Sleeves

Bushing sleeves are cylindrical components used in mechanical systems to provide a bearing surface between rotating and stationary parts. They help reduce friction and wear, thereby contributing to the longevity and efficiency of machinery. In the context of commercial trucks, bushing sleeves are vital for ensuring smooth operation and minimizing maintenance needs 1.

Purpose of the 3942013 Bushing Sleeve

This part is specifically designed to fit within the mechanical system of a truck, where it supports and guides moving parts. Its placement is crucial for maintaining the alignment and function of connected components. By providing a low-friction surface, the bushing sleeve helps in reducing wear and tear on the parts it interfaces with, thus contributing to the overall durability of the truck’s mechanical system.

Key Features

The 3942013 is constructed from high-quality materials that offer superior resistance to wear and corrosion. Its design includes precise tolerances to ensure a snug fit within the truck’s mechanical system. Additionally, the bushing sleeve may feature unique characteristics such as anti-rotation tabs or lubrication grooves, which enhance its performance and longevity.

Benefits

The incorporation of the 3942013 into a truck’s mechanical system offers several benefits. These include improved durability of the mechanical components it supports, reduced wear on connected parts, and enhanced overall performance of the truck. The bushing sleeve’s ability to minimize friction also contributes to more efficient operation, potentially leading to fuel savings over time.

Installation Process

Installing this part requires careful attention to detail to ensure proper fit and function. The process involves cleaning the installation area, aligning the bushing sleeve with the corresponding components, and securing it in place. Tools such as presses or alignment tools may be required to ensure the bushing sleeve is installed correctly.

Troubleshooting Common Issues

Common issues associated with bushing sleeves can include wear, misalignment, or damage due to excessive load or contamination. Addressing these problems may involve inspecting the bushing sleeve for signs of wear, ensuring proper alignment of connected components, or cleaning the installation area to remove contaminants. Regular maintenance and inspection can help prevent these issues.

Maintenance Tips

To ensure the longevity and optimal performance of the 3942013, regular maintenance is recommended. This includes periodic inspection for signs of wear or damage, cleaning the installation area to prevent contamination, and ensuring that connected components are properly aligned. Following the manufacturer’s guidelines for maintenance can help maximize the lifespan of the bushing sleeve.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and aftermarket parts. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company’s extensive product range and commitment to customer satisfaction make it a preferred choice for commercial truck operators worldwide.

Bushing Sleeve 3942013 Compatibility with Cummins Engines

This part is a critical component that fits into various Cummins engine models. This part is essential for maintaining the integrity and functionality of the engine’s internal mechanisms. Below is a detailed description of the engine models with which this bushing sleeve is compatible.

ISB Series

- ISB CM2150

- ISB CM550

- ISB CM850

- ISB/ISD4.5 CM2150 B119

- ISB/ISD6.7 CM2150 SN

- ISB4.5 CM2350 B104

- ISB5.9 CM2880 B110

- ISB6.7 CM2250

- ISB6.7 CM2350 B101

The ISB series engines are known for their robust design and high performance, making them suitable for a variety of applications, from heavy-duty trucks to industrial machinery. The Bushing Sleeve 3942013 is designed to fit seamlessly into these engines, ensuring smooth operation and longevity.

ISBE Series

- ISBE CM2150

- ISBE4 CM850

The ISBE series engines are engineered for high-efficiency and low emissions, making them ideal for applications where environmental considerations are paramount. This part is compatible with these engines, providing the necessary support and alignment for optimal performance.

ISC Series

- ISC CM2150

- ISC CM554

- ISC CM850

The ISC series engines are designed for applications requiring high torque and durability. This part fits these engines, ensuring that the internal components remain properly aligned and protected.

ISD Series

- ISD4.5 CM2220 D108

The ISD series engines are built for heavy-duty applications, offering exceptional power and reliability. This part is a crucial component for these engines, maintaining the alignment of critical parts and ensuring smooth operation.

ISF Series

- ISF3.8 CM2220 AN

The ISF series engines are designed for applications that require a balance of power and efficiency. This part is compatible with these engines, providing the necessary support for their internal components.

ISL Series

- ISL CM2150

- ISL CM554

- ISL9 CM2150 SN

The ISL series engines are known for their versatility and performance, making them suitable for a wide range of applications. This part fits these engines, ensuring that they operate smoothly and efficiently.

ISZ Series

- ISZ13 CM2150 Z105

The ISZ series engines are designed for applications requiring high power and efficiency. This part is compatible with these engines, providing the necessary support and alignment for optimal performance.

This bushing sleeve is a vital component for the engines listed above, ensuring that they function correctly and efficiently. Its compatibility with a wide range of Cummins engines underscores its importance in maintaining the performance and reliability of these powerful machines.

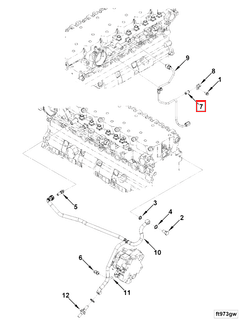

Role of Part 3942013 Bushing Sleeve in Engine Systems

This part is an essential component in various engine systems, facilitating smooth operation and efficient performance. It is strategically positioned within the fuel system to ensure optimal functionality of several key components.

Fuel System Integration

In the fuel system, the 3942013 Bushing Sleeve is integral to the fuel filter and fuel plumbing. It provides a secure connection between the fuel supply tube and the fuel filter, ensuring a leak-free passage of fuel. This component also plays a role in the fuel drain tube and fuel drain tube kit, allowing for efficient drainage and maintenance of the fuel system.

Injector and Plumbing Connections

The Bushing Sleeve is utilized in the injector fuel supply tube and injector plumbing, where it ensures a stable connection that prevents fuel leaks and maintains consistent fuel pressure. This is vital for the precise operation of the injector, which relies on a steady fuel supply for optimal performance.

Fuel Transfer and Pump Systems

Within the fuel transfer tube and fuel transfer pump systems, the 3942013 Bushing Sleeve helps in maintaining the integrity of the fuel lines. It ensures that the fuel transfer process is smooth and uninterrupted, which is essential for the overall efficiency of the engine.

Catalytic Converter and Cooler Systems

In systems involving the catalytic converter and cooler, the Bushing Sleeve aids in the secure attachment of various components. This ensures that the exhaust gases are effectively managed and that the cooling system operates efficiently, contributing to the engine’s performance and longevity.

Engine Control Module and Performance

The integration of the Bushing Sleeve within the engine control module (ECM) plumbing ensures that all fuel-related sensors and actuators receive a consistent and reliable fuel supply. This consistency is key to the ECM’s ability to make accurate adjustments to the engine’s performance parameters.

Campaign Kit and Maintenance

In campaign kits designed for engine maintenance and upgrades, the 3942013 Bushing Sleeve is often included to ensure that all new components are properly connected and sealed. This is particularly important in high-performance engines where precision and reliability are paramount.

The 3942013 Bushing Sleeve, through its various applications, plays a significant role in maintaining the efficiency and reliability of engine systems. Its presence ensures that fuel systems, injectors, and various plumbing connections operate seamlessly, contributing to the overall performance and durability of the engine.

Conclusion

The Bushing Sleeve 3942013 is a critical component in the maintenance and operation of Cummins engines. Its role in reducing friction, ensuring proper alignment, and facilitating efficient fuel transfer and management is essential for the longevity and performance of commercial trucks. Regular maintenance and proper installation are key to maximizing the benefits of this part, ensuring that engines operate smoothly and efficiently.

-

BT Fijalkowski, Automotive Mechatronics Operational and Practical Issues Volume 1, Springer, 2011.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.