This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Bushing part 4322656, manufactured by Cummins, is a specialized component designed for use in commercial trucks and various engine models. Cummins, a well-established name in the automotive industry, produces a wide range of parts that contribute to the efficiency and reliability of heavy-duty vehicles. Bushings, in general, play a significant role in mechanical systems by providing support and reducing friction between moving parts. This particular bushing is integral to the operation of commercial trucks and engines, enhancing their performance and durability.

Basic Concepts of Bushings

Bushings are cylindrical components used to reduce friction, wear, and noise between moving parts in mechanical systems. They differ from other types of bearings, such as ball bearings, by providing a solid surface for rotation or oscillation rather than rolling elements. Bushings are typically made from materials like bronze, nylon, or various polymers, each offering distinct properties such as load-bearing capacity, wear resistance, and thermal stability. The choice of material depends on the specific application and the operating conditions the bushing will encounter 1.

Purpose of Bushing 4322656 in Truck and Engine Operation

Bushing 4322656 is specifically designed to support and align components within the truck’s and engine’s mechanical system, reducing friction and wear on moving parts. By doing so, it contributes to the smooth operation of the truck and engine, enhancing their overall performance and longevity. This bushing plays a role in maintaining the alignment and stability of critical components, ensuring that they function efficiently under the demanding conditions typical of commercial truck and engine operations 2.

Key Features of Bushing 4322656

Bushing 4322656 features a design that maximizes its performance and durability in commercial truck and engine applications. It is composed of high-quality materials selected for their strength, wear resistance, and ability to operate under high loads and temperatures. The bushing’s design includes precision machining to ensure a perfect fit within the truck’s and engine’s mechanical system, minimizing the risk of misalignment or excessive wear. Additionally, it may incorporate special coatings or treatments to further enhance its performance and longevity.

Benefits of Using Bushing 4322656

The use of Bushing 4322656 offers several advantages in commercial truck and engine applications. Its durable construction and precise design contribute to improved performance and reduced maintenance requirements. By minimizing friction and wear on moving parts, this bushing helps to extend the lifespan of critical components, reducing the need for frequent replacements. Furthermore, its reliable operation under demanding conditions ensures that trucks and engines can maintain high levels of performance and efficiency over time 3.

Installation and Integration

Proper installation of Bushing 4322656 is crucial to ensure its effective operation within the truck’s and engine’s mechanical system. Installation guidelines recommend careful alignment and secure fitting to prevent misalignment or excessive wear. Specific requirements may include the use of lubricants or sealants to enhance performance and protect against corrosion. Integrating this bushing into a truck’s or engine’s system requires attention to detail to ensure compatibility with other components and adherence to manufacturer specifications.

Troubleshooting Common Issues

Common issues associated with bushings include wear, misalignment, and failure due to excessive loads or temperatures. Troubleshooting Bushing 4322656 involves identifying signs of wear or damage, such as unusual noise, vibration, or decreased performance. Addressing these issues may require inspection, cleaning, or replacement of the bushing. Regular maintenance and monitoring can help prevent serious problems and ensure the continued reliable operation of the truck and engine.

Maintenance Tips

Regular maintenance of Bushing 4322656 is key to ensuring optimal performance and longevity. Maintenance tips include periodic inspection for signs of wear or damage, cleaning to remove contaminants that could accelerate wear, and lubrication to reduce friction and heat. Replacement schedules should be based on the manufacturer’s recommendations or as dictated by the condition of the bushing. Adhering to these maintenance practices can help extend the life of the bushing and maintain the efficiency of the truck and engine.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a trusted name in the commercial truck and engine industry, known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of heavy-duty applications. Cummins’ dedication to excellence and continuous improvement ensures that its products, including Bushing 4322656, deliver reliable performance and durability in commercial truck and engine operations.

Role of Part 4322656 Bushing in Engine Systems

The 4322656 Bushing is an integral component in the assembly and operation of several engine systems. Its primary function is to provide a smooth and low-friction interface between moving parts, thereby enhancing the efficiency and longevity of the engine.

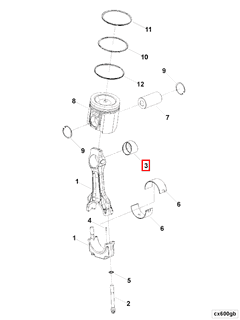

Interaction with Engine Connecting Rod

In the engine connecting rod system, the 4322656 Bushing is positioned to facilitate the connection between the rod and the crankshaft. This bushing allows for the necessary rotational movement while minimizing wear and tear on the connecting rod. By reducing friction, it ensures that the connecting rod can efficiently transfer the piston’s linear motion to the crankshaft’s rotational motion, contributing to the overall performance and reliability of the engine.

Integration with Engine Piston

When integrated with the engine piston, the 4322656 Bushing plays a role in the piston pin (wrist pin) system. It is placed within the piston or the small end of the connecting rod to allow for smooth articulation as the piston moves up and down. This bushing helps in maintaining the alignment and reducing the stress on the piston pin, which is essential for the piston’s consistent and precise movement within the cylinder.

Function in Wiring Retainer Bracket

Although less commonly associated, the 4322656 Bushing can also be utilized in the wiring retainer bracket system. Here, it serves to secure wiring harnesses and electrical components in place while allowing for some degree of movement to accommodate engine vibrations and thermal expansion. This application ensures that the wiring remains intact and functional under varying operational conditions, contributing to the engine’s electrical system reliability.

Conclusion

Bushing 4322656, manufactured by Cummins, is a critical component in commercial trucks and various engine models. Its design and features contribute to the smooth operation, performance, and longevity of these vehicles and engines. Proper installation, maintenance, and troubleshooting are essential to ensure the reliable operation of this bushing in demanding commercial applications.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.